Polyamide acid composition and preparation method and application thereof

A technology of polyamic acid and composition, which is applied to polyamic acid composition and the fields of preparation and application thereof, can solve the problems of unstable viscosity control, difficulty in increasing polymer molecular chain, etc., and achieve the effect of good technical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

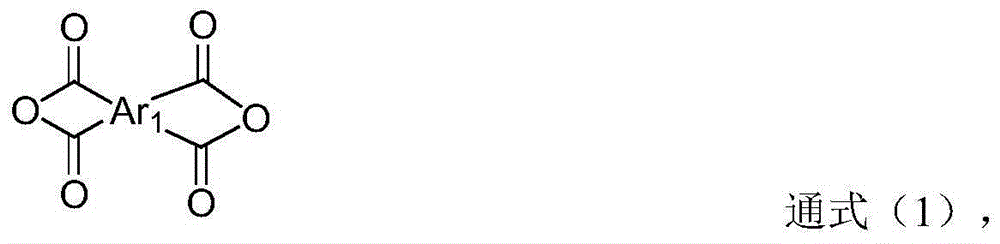

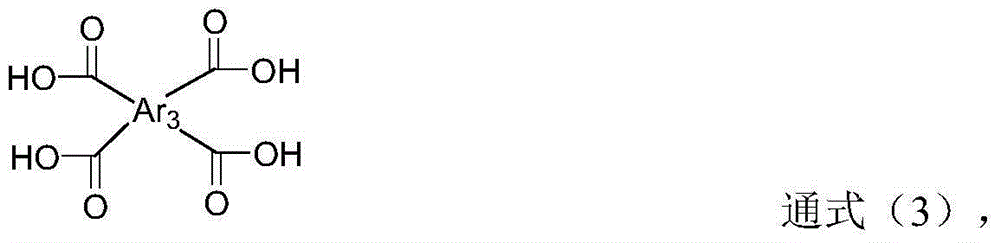

Method used

Image

Examples

Embodiment 1

[0051] Add 10.814g (0.1mol) of p-phenylenediamine and 243ml N,N-dimethylacetamide in the four-necked flask (water content 380ppmw), stir at room temperature and 2 Under protection, after completely dissolving, cool in an ice-water bath to 0°C, add 0.3303g (0.001mol) 3,3′,4,4′-biphenyltetraic acid, stir within the temperature range of 0°C, and the stirring speed is 200 rpm , after completely dissolving, maintain the reaction for 1 hour to obtain a reddish-brown solution, then add 29.1278g (0.099mol) 3,3',4,4'-biphenyltetraacid dianhydride powder to the solution obtained above, Stirring was continued for 5 hours to obtain a light yellow transparent viscous solution, and a desired polyamic acid composition solution with a solid content of 14.8%. After testing, the kinematic viscosity is 146Pa·s at 25°C, and the intrinsic viscosity is 1.58dL / g at 25°C.

Embodiment 2

[0053] Add 10.814g (0.1mol) of p-phenylenediamine and 170ml N,N-dimethylacetamide in the four-necked flask (water content 380ppmw), stir at room temperature and 2 Under protection, after completely dissolving, cool in an ice-water bath to 0°C, add 0.6606g (0.002mol) of 3,3′,4,4′-biphenyltetraacid, stir within a temperature range of 40°C, and the stirring speed is 250 rpm , after completely dissolving, maintain the reaction for 1 hour to obtain a reddish-brown solution, then add 28.8336g (0.098mol) 3,3',4,4'-biphenyltetraacid dianhydride powder to the solution obtained above, Stirring was continued for 5 hours to obtain a red-yellow solution, and the desired polyamic acid composition solution with a solid content of 20.0% was obtained. After testing, the kinematic viscosity is 68Pa·S at 25°C, and the intrinsic viscosity is 0.95dL / g at 25°C.

Embodiment 3

[0055] 10.814g (0.1mol) of p-phenylenediamine and 346ml N-methylpyrrolidone (water content 800ppmw) were added in the four-necked flask, stirred at room temperature and heated under N 2 Under protection, after completely dissolving, cool in an ice-water bath to 0°C, add 1.321g (0.004mol) 3,3′,4,4′-biphenyltetraic acid, stir within a temperature range of 30°C, and the stirring speed is 250 rpm , after completely dissolving, maintain the reaction for 1 hour to obtain a reddish-brown solution, then add 28.2451g (0.096mol) 3,3',4,4'-biphenyltetraacid dianhydride powder to the solution obtained above, Stirring was continued for 6 hours to obtain a black solution, and the desired polyamic acid composition solution with a solid content of 10.0% was obtained. After testing, the kinematic viscosity is 38Pa·S at 25°C, and the intrinsic viscosity is 0.62dL / g at 25°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Kinematic viscosity | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

| Kinematic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com