Polycarboxylic acid water-coal-slurry additive as well as preparation method and application thereof

A coal-water slurry and polycarboxylic acid technology, applied in the field of coal-water slurry additives, can solve the problems of high cost of synthetic raw materials, difficult molecular weight of additives, and high viscosity of coal-water slurry, so as to reduce pulping viscosity and raw material costs, and benefit product molecular weight Size, the effect of suppressing the phenomenon of burst aggregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

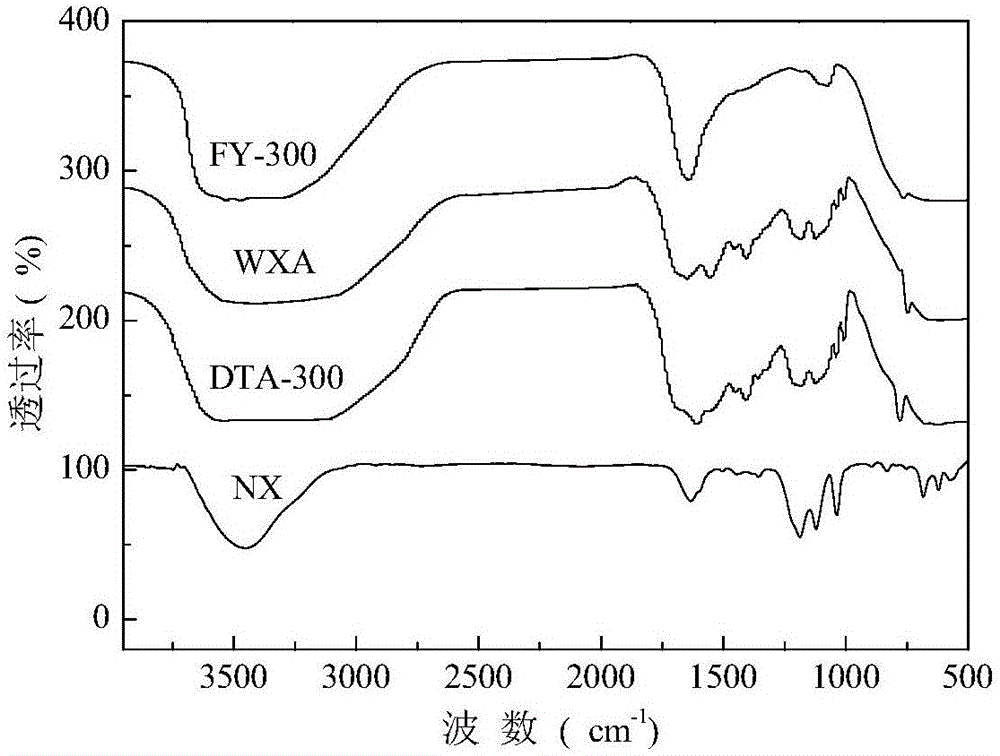

Image

Examples

Embodiment 1

[0057] 1. Preparation of low-rank coal hydrothermal treatment waste liquid:

[0058] (1) Inner Mongolia Autonomous Region Dongming lignite (marked as DM) was crushed and ground to make pretreated coal water slurry, the average particle diameter D50 of coal powder in the pretreated coal water slurry was 50 μm, and the concentration was 30% by weight.

[0059] (2) Preheat the pretreated coal-water slurry prepared in step (1) to 300°C, and then use a 0.1t / d (dry coal) continuous hydrothermal reaction device to hydrothermally treat it at 300°C and 8.7MPa for 1 hour.

[0060] (3) Carry out vacuum suction filtration to the water coal slurry after hydrothermal treatment obtained in step (2), filter cake is hydrothermal upgrading coal (marked as DMU); Collect filtrate (marked as FY-300), and Concentrate under vacuum at 60°C to a solid content of about 10% by weight, and seal and store for future use.

[0061] 2. Preparation of polycarboxylate coal-water slurry additive:

[0062] (4)...

Embodiment 2

[0074] 1. Preparation of low-rank coal hydrothermal treatment waste liquid:

[0075] (1) Inner Mongolia Autonomous Region Dongming lignite (marked as DM) was crushed and ground to make pretreated coal water slurry, the average particle diameter D50 of coal powder in the pretreated coal water slurry was 50 μm, and the concentration was 30% by weight.

[0076] (2) Preheat the pretreated coal-water slurry prepared in step (1) to 325°C, and then use a 0.1t / d (dry coal) continuous hydrothermal reaction device to hydrothermally treat it at 325°C and 12.4MPa for 1 hour.

[0077] (3) Carry out vacuum suction filtration to the water coal slurry after the hydrothermal treatment that obtains in step (2), collect filtrate (marked as FY-325), and under 60 ℃ vacuumize and concentrate to solid content about 10% by weight, Sealed and kept for later use.

[0078] 2. Preparation of polycarboxylate coal-water slurry additive:

[0079] (4) Polyethylene glycol (the number average molecular weigh...

Embodiment 3

[0085] 1. Preparation of low-rank coal hydrothermal treatment waste liquid:

[0086] (1) Inner Mongolia Autonomous Region Dongming lignite (marked as DM) was crushed and ground to make pretreated coal water slurry, the average particle diameter D50 of coal powder in the pretreated coal water slurry was 50 μm, and the concentration was 30% by weight.

[0087] (2) Preheat the pretreated coal-water slurry prepared in step (1) to 250°C, and then use a 0.1t / d (dry coal) continuous hydrothermal reaction device to hydrothermally treat it at 250°C and 4.0MPa for 1.5h.

[0088] (3) Carry out vacuum suction filtration to the water coal slurry after the hydrothermal treatment obtained in step (2), collect filtrate (marked as FY-250), and vacuumize and concentrate at 60 DEG C to a solid content of about 10% by weight, Sealed and kept for later use.

[0089] 2. Preparation of polycarboxylate coal-water slurry additive:

[0090] (4) Polyethylene glycol (number average molecular weight is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Number average molecular weight | aaaaa | aaaaa |

| Number average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com