Teicoplanin purifying method

A technology of teicoplanin and purification method, which is applied in the field of purification of teicoplanin, can solve problems affecting the production environment and personnel health, unsatisfactory decolorization and impurity removal effects, and relatively large impact of teicoplanin control. Achieve the effect of avoiding residue problems, good decolorization effect and large preparation volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

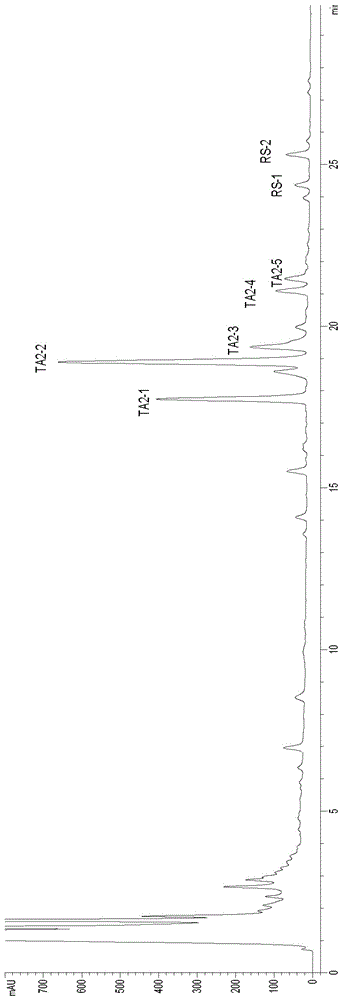

[0048] Get 10L of teicoplanin fermentation broth, adjust the pH value to 11.0, then adopt plate and frame filtration to obtain the teicoplanin filtrate; the teicoplanin filtrate is pumped into the pretreated polar large Pore adsorption HT60 (20-60 mesh) resin chromatography column (Φ10×120cm); then washed with purified water until colorless, and then at an elution rate of 1.5L / h, the volume ratio was sequentially 10:90, 20: 80, 30:70, 40:60 ethanol-water solution (analysis solution) for gradient elution, and the analysis solution used for each gradient elution is 3 times the volume of the packed bed, and the enrichment solution is collected to obtain teicoplanin rich Collect liquid, adopt high performance liquid chromatography to detect this teicoplanin enriched liquid, then detection result is as follows figure 2 shown;

[0049] The obtained teicoplanin enrichment solution was diluted with an equal volume of purified water and then pretreated with a medium-polarity HN60 (...

Embodiment 2

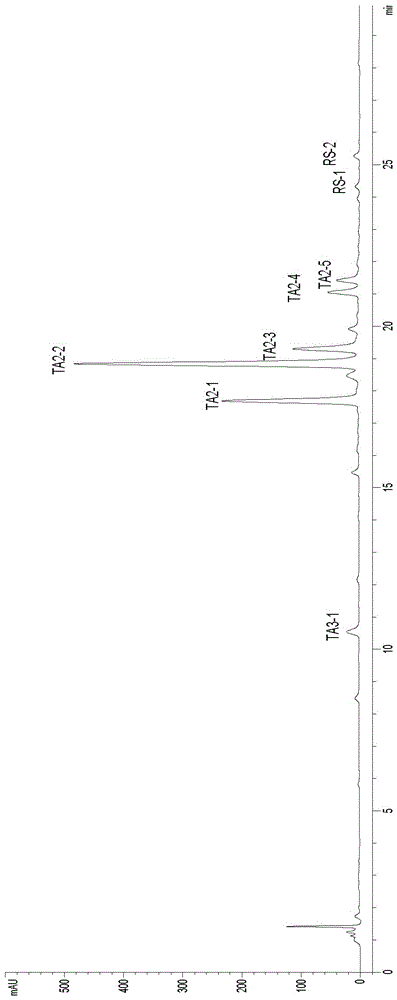

[0051] Get 100L of teicoplanin fermentation broth, adjust the pH value to 10.0, then adopt plate and frame filtration to obtain the teicoplanin filtrate; the teicoplanin filtrate is pumped into the pretreated polar large Pore adsorption HT60 (20-60 mesh) resin chromatography column (Φ25×200cm); then wash with purified water until colorless, and then use gradients at a volume ratio of 10:90 and 20:80 at an elution rate of 20L / h , 30:70, 40:60 ethanol-water solution (analysis solution) for gradient elution, and the analysis solution used for each gradient elution is 5 times the volume of the packed bed, and the enrichment solution is collected to obtain teicoplanin enrichment liquid;

[0052] The obtained teicoplanin enrichment solution was diluted with an equal volume of purified water and pretreated with a medium-polarity HN60 (100 mesh) macroporous adsorption resin column (Φ25×200cm); then washed with purified water until it was colorless, and then washed with 15 L / The el...

Embodiment 3

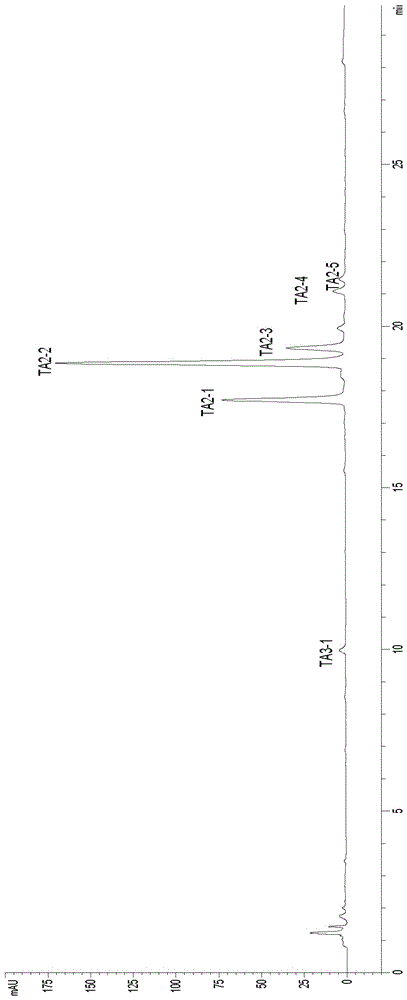

[0054] Get 800L of teicoplanin fermentation broth, adjust the pH value to 12.0, then adopt plate and frame filtration to obtain the teicoplanin filtrate; the teicoplanin filtrate is pumped into the pretreated polar large Pore adsorption HT60 (20-60 mesh) resin chromatography column (Φ50×300cm); then wash with purified water until colorless, and then use gradients at a volume ratio of 10:90 and 20:80 at an elution rate of 60L / h , 30:70, 40:60 ethanol-water solution (analysis solution) for gradient elution, and the analysis solution used for each gradient elution is 5 times the volume of the packed bed, and the enrichment solution is collected to obtain teicoplanin enrichment liquid;

[0055] The obtained teicoplanin enrichment solution was diluted with an equal volume of purified water and pretreated with a medium-polarity HN60 (100 mesh) macroporous adsorption resin column (Φ60×250cm); then washed with purified water until it was colorless, and then washed with 40 L / The el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com