High-energy-density explosive mixture and preparation method thereof

A technology of high energy density and mixed explosives, applied in directions such as explosives, can solve the problems of limitation, slow deflagration speed and energy release rate, etc., and achieve the effect of simple and practical preparation method and strong practical value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

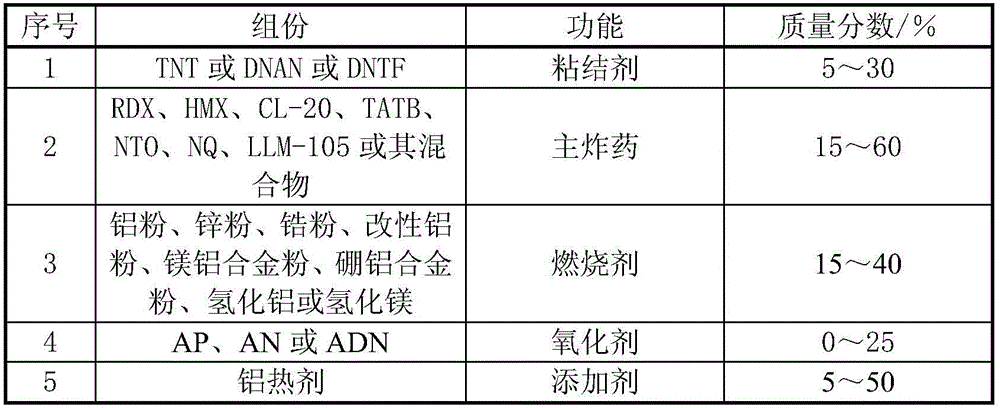

[0021] Embodiment 1: Add Al / Fe 2 o 3 TNT-based high energy density explosives

[0022] Formula composition (mass percentage) is as follows:

[0023]

[0024] The explosive preparation process is as follows:

[0025] ① Premix

[0026] Weigh TNT, RDX, Al and thermite Al / Fe in proportion 2 o 3 , mechanical mixing;

[0027] ②Hot pressing

[0028] Spread the explosive powder mixture in the mold, raise the temperature to 45°C (TNT melting point 80°C), vacuumize, the vacuum degree is -0.094MPa, mechanically pressurize to 40MPa, and hold the pressure for 120min;

[0029] ③ post-processing

[0030] Release the pressure at a rate of 2MPa / s, lower the temperature at a rate of 1°C / min to normal temperature and pressure, and open the mold to obtain a high energy density mixed explosive sample. The density and heat of detonation are shown in Table 2.

Embodiment 2

[0031] Embodiment 2: Add the DNAN base high energy density explosive of Al / CuO

[0032] Formula composition (mass percentage) is as follows:

[0033]

[0034] The explosive preparation process is as follows:

[0035] ① Premix

[0036] Weigh DNAN, NTO, AP, zirconium powder and thermite Al / CuO in proportion, and mix them mechanically;

[0037] ②Hot pressing

[0038] Spread the explosive powder mixture in the mold, raise the temperature to 55°C (DNAN melting point 96°C), vacuumize, the vacuum degree is -0.092MPa, mechanically pressurize 80MPa, and hold the pressure for 90min;

[0039] ③ post-processing

[0040] Release the pressure at a rate of 1MPa / s, lower the temperature at a rate of 0.5°C / s, drop to normal temperature and pressure, and open the mold to obtain a high energy density mixed explosive sample. The density and heat of detonation are shown in Table 2.

Embodiment 3

[0041] Embodiment 3: adding Al / WO 2 DNAN-based High Energy Density Explosives

[0042] Formula composition (mass percentage) is as follows:

[0043]

[0044] The explosive preparation process is as follows:

[0045] ① Premix

[0046] Weigh DNAN, NTO, RDX, aluminum powder and thermite Al / WO in proportion 2 , mechanical mixing;

[0047] ②Hot pressing

[0048] Spread the explosive powder mixture in the mold, raise the temperature to 60°C (DNAN melting point is 96°C), vacuumize, the vacuum degree is -0.092MPa, mechanically pressurize to 80MPa, and hold the pressure for 90min;

[0049] ③ post-processing

[0050] Release the pressure at a rate of 0.8MPa / s, lower the temperature at a rate of 0.5°C / s, drop to normal temperature and pressure, and open the mold to obtain a high energy density mixed explosive sample. The density and heat of detonation are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com