A microporous hollow nickel oxide gas-sensitive sensing material and device for selective adsorption of formaldehyde and its preparation and application

A sensing material and selective technology, which is applied in nickel oxide/nickel hydroxide, material resistance, analytical materials, etc., can solve the problem of not synthesizing NiO porous hollow sphere structure, so as to improve the gas response rate, increase the active vacancies, The effect of stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

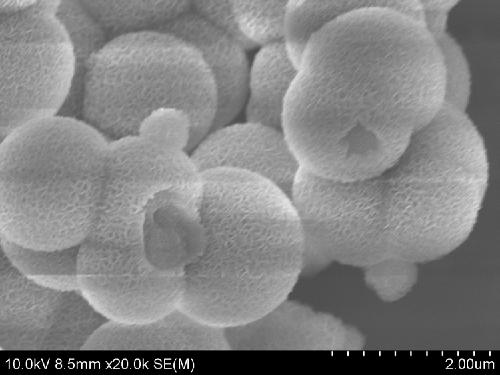

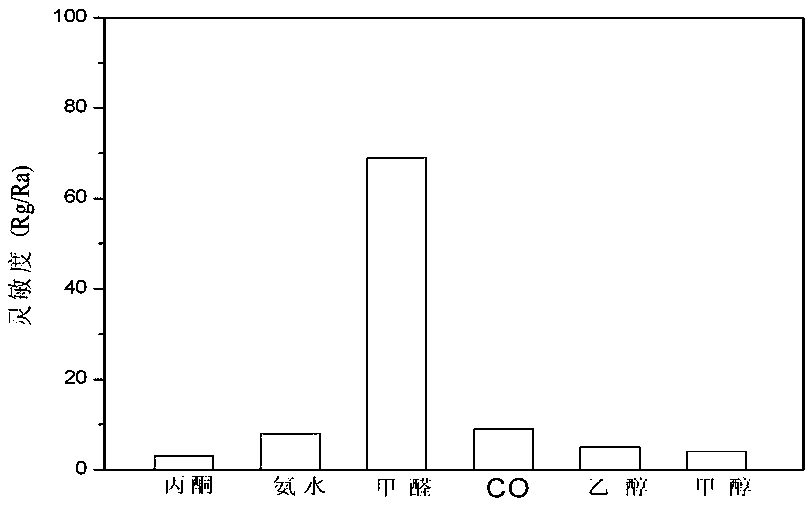

[0024] Weigh 1g of nanocellulose dissolved in 20ml of water and put it into a mixed solution of deionized water and DMSO, stir at room temperature for 20min, add 0.0580g of nickel nitrate and 0.1402g of HMTA; put the beaker into a drying oven at 60°C for 24 hours ;When the temperature of the reaction kettle drops to room temperature, wash the green suspension with alcohol and water for 3-5 times respectively; put it into a muffle furnace and heat it up to 300°C at 5°C / min for 10 hours to obtain microporous hollow nickel oxide balls , the diameter of the hollow sphere is between 1-2 microns ( figure 1 ), put the microporous hollow spheres in alcohol or water for later use; clean the alumina ceramic tubes with deionized water, acetone, and chloroform, dry them, apply the NiO paste evenly on the surface of the ceramic tubes, weld the electrodes, and package them. Aging at 200° C. for 10 days to obtain a gas sensor. The WS-30A gas sensor test system is used to test the response o...

Embodiment 2

[0026] Weigh 1g of nanocellulose and dissolve 20ml of water into a mixed solution of deionized water and DMSO, stir at room temperature for 20min, add 0.0518g of nickel chloride and 0.1402g of HMTA; put the beaker into a dry box at 95°C for 5 Hours; when the temperature of the reactor drops to room temperature, wash the green suspension with alcohol and water for 3-5 times respectively; put it into a muffle furnace and heat it up to 600°C at 10°C / min for 2 hours to obtain microporous hollow nickel oxide Balls, hollow balls with a diameter of 2-2.5 microns, put the microporous hollow balls in alcohol or water for use; clean the alumina ceramic tubes with deionized water, acetone, and chloroform, dry them, and evenly coat the NiO paste Spread on the surface of the ceramic tube, weld the electrodes, package, and age at 300°C for 5 days to obtain the gas sensor. The WS-30A gas sensor test system is used to test the response of different gases with a concentration of 1ppm. It has a...

Embodiment 3

[0028] Weigh 1g of nanocellulose dissolved in 20ml of water and put it into a mixed solution of deionized water and DMSO, stir at room temperature for 20min, 0.1467g of nickel oxalate and 0.5608g of HMTA; put the beaker into a drying oven at 75°C for 12 hours; After the temperature of the reaction kettle drops to room temperature, wash the green suspension with alcohol and water for 3-5 times respectively; put it into a muffle furnace and raise the temperature to 450°C at 3°C / min for 6 hours to obtain microporous hollow nickel oxide balls. The diameter of the hollow sphere is between 2-2.5 microns, and the microporous hollow sphere is placed in alcohol or water for use; the alumina ceramic tube is cleaned with deionized water, acetone, and chloroform, dried, and the NiO paste is evenly coated on the The surface of the ceramic tube is welded with electrodes, packaged, and aged at 250°C for 7 days to obtain a gas sensor. The WS-30A gas sensor test system is used to test the resp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com