Water treatment agent based on laminated composite metal hydroxide and preparation method of water treatment agent

A hydroxide and layered composite technology, applied in the direction of oxidized water/sewage treatment, water/sewage treatment, chemical instruments and methods, etc., can solve the problems of complex preparation, high cost, difficult regeneration, etc., and achieve simple preparation process, The effect of low cost and reproducible products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

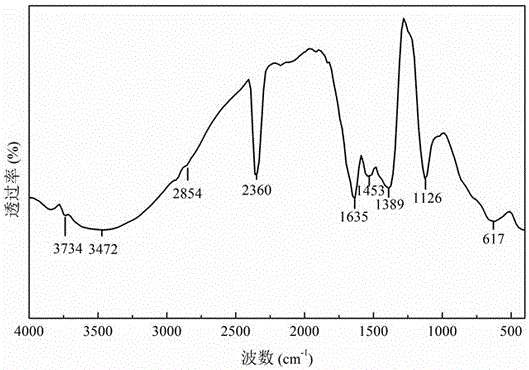

Image

Examples

Embodiment 1

[0035] A method for preparing a water treatment agent based on layered composite metal hydroxides includes the following steps in sequence:

[0036] (1) Prepare a mixed solution of magnesium nitrate and aluminum nitrate with a concentration of 1 mol / L as solution A, and the molar ratio of magnesium to aluminum ions in solution A is 2:3;

[0037] (2) Prepare a mixed lye composed of sodium hydroxide and sodium carbonate as solution B, in which the molar concentration of sodium carbonate is 1.2 mol / L and the molar concentration of sodium hydroxide is 1.6 mol / L;

[0038] (3) Drop A solution and B solution into 200 mL deionized water at a constant speed of 200 mL / h, keep stirring throughout the titration process; continue to stir evenly after the titration is completed, and let stand for 3 hours in a water bath at 80°C for crystallization;

[0039] (4) Centrifugally separate the crystallization mixture and wash the solid with deionized water, recrystallize with ethanol, dry at 80 degrees, a...

Embodiment 2

[0044] A method for preparing a water treatment agent based on layered composite metal hydroxides includes the following steps in sequence:

[0045] (1) Prepare a mixed solution of magnesium nitrate and aluminum nitrate with a concentration of 1 mol / L as solution A, and the molar ratio of magnesium to aluminum ions in solution A is 1:1;

[0046] (2) Prepare a mixed lye composed of sodium hydroxide and sodium carbonate as solution B, in which the molar concentration of sodium carbonate is 1.2 mol / L and the molar concentration of sodium hydroxide is 1.6 mol / L;

[0047] (3) Drop A solution and B solution into 200 mL deionized water at a constant speed of 200 mL / h, and keep stirring throughout the titration process. After the titration is completed, continue to stir evenly, and let it stand for 3 hours to crystallize in a water bath at 80°C;

[0048] (4) Centrifugal separation and wash the obtained solid with deionized water, recrystallize with ethanol, dry at 80 degrees, and grind;

[004...

Embodiment 3

[0052] A method for preparing a water treatment agent based on layered composite metal hydroxides includes the following steps in sequence:

[0053] (1) Prepare a mixed solution of zinc nitrate and aluminum nitrate with a concentration of 1 mol / L as solution A, and the molar ratio of zinc and aluminum ions in solution A is 4:1;

[0054] (2) Prepare a mixed lye composed of sodium hydroxide and sodium carbonate as solution B, in which the molar concentration of sodium carbonate is 1.2 mol / L and the molar concentration of sodium hydroxide is 1.6 mol / L;

[0055] (3) Drop A solution and B solution into 200 mL deionized water at a constant speed of 200 mL / h, and keep stirring throughout the titration process. After the titration is completed, continue to stir evenly, and stand for crystallization in a water bath at 80°C for 24 hours;

[0056] (4) Centrifugal separation and wash the obtained solid with deionized water, recrystallize with ethanol, dry at 80 degrees, and grind;

[0057] (5) Pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com