Vacuum forming device for gypsum mold

A vacuum forming and gypsum technology, which is applied in the directions of casting mold components, casting molding equipment, casting molds, etc., can solve the problems of restricting the reliability and scope of application of gypsum molds, weak fluidity of gypsum mixture, and poor quality stability of molds. Improve work efficiency and mold forming quality and precision, high forming efficiency and forming precision, and low cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

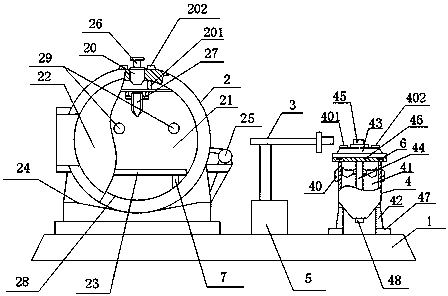

[0012] Such as figure 1 A gypsum casting vacuum forming device shown includes a positioning base 1, a vacuum forming cabin 2, a transfer boom 3 and a gypsum vacuum mixing cabin 4, and the vacuum forming cabin 2 and the transfer boom 3 are installed on the On the positioning base 1 , the gypsum mixing cabin 4 is respectively connected with the positioning base 1 and the vacuum forming cabin 2 through the transfer boom 3 .

[0013] In the present embodiment, the gypsum mixing cabin 4 includes a mixing tank 41, a supporting leg 42, a sealing cover 43, a stirring device 44 and a stirring driving device 45, and the top of the mixing tank 41 is provided with a connection port 46, and through the connection port 46 and The sealing cover 43 is connected, and at least three supporting legs 42 are arranged on the outer surface of the bottom of the mixing tank 41, and the end of the supporting legs 42 is provided with a connecting block 47, and is respectively connected with the position...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com