Preparation method of two-dimensional and three-dimensional carrier reinforced carbon nitride photocatalytic material

A catalytic material and three-dimensional technology, applied in the field of photocatalysis, can solve the problems of affecting the photocatalytic effect of photocatalysts, low photocatalytic activity, difficulty in wide application, and reduced photocatalytic efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

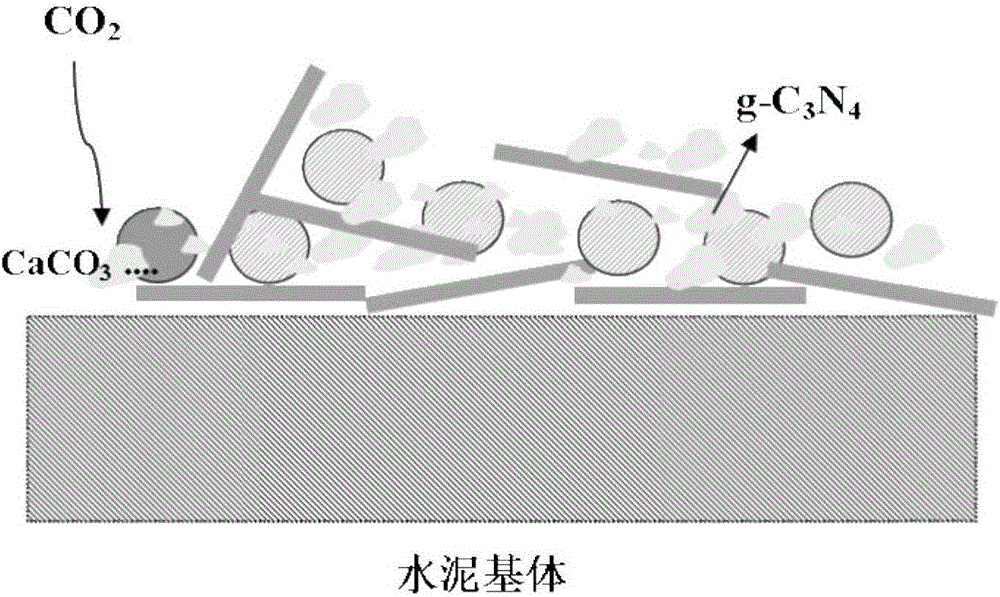

[0027] Embodiment 1 discloses a kind of preparation method of two-dimensional, three-dimensional carrier enhanced carbon nitride photocatalytic material, principle is as follows figure 1 shown, including the following steps:

[0028] S1: Disperse 5g of mica powder in 200mL of ethanol, the mass percentage of mica powder is 3%, stir and disperse for 1h, after fully swelling, put it into a cell crusher, ultrasonic at 400W for 4h, and then go through centrifugal drying, use ultrasonic The cavitation effect will peel mica powder into two-dimensional flake mica;

[0029] S2: Put 10 g of glass microspheres into a ball mill and mill at 300 rpm for half an hour. The obtained three-dimensional glass powder is passed through 600 mesh and 800 mesh sieves to obtain three-dimensional glass powder with a particle size between 600 and 800 mesh;

[0030] S3: Weigh 0.6g of two-dimensional flaky mica, 0.4g of three-dimensional glass powder and 20g of urea into 20mL of deionized water to obtain ...

Embodiment 2

[0035] Embodiment 2 discloses a method for preparing a two-dimensional, three-dimensional carrier-enhanced carbon nitride photocatalytic material, comprising the following steps:

[0036] Disperse 2g of mica powder in 200mL of deionized water. The mass percentage of mica powder is 1%. Stir and disperse for 2 hours. The mica powder is exfoliated into two-dimensional flake mica by chemical reaction;

[0037] S2: Put 10 g of glass microspheres into a ball mill and mill at 300 rpm for half an hour. The obtained three-dimensional glass powder is passed through 600 mesh and 800 mesh sieves to obtain three-dimensional glass powder with a particle size between 600 and 800 mesh;

[0038] S3: Weigh 0.2g of two-dimensional flaky mica, 0.2g of three-dimensional glass powder and 20g of melamine into 20mL of deionized water to obtain a mixture. The mass percentages of each component in the mixture in the total mixture are: two-dimensional sheet 1% mica, 1% three-dimensional glass powder, 9...

Embodiment 3

[0041] Embodiment 3 discloses a method for preparing a two-dimensional, three-dimensional carrier-enhanced carbon nitride photocatalytic material, comprising the following steps:

[0042] Disperse 20g of mica powder in 200mL of deionized water. The mass percentage of mica powder is 10%. Stir and disperse for 3 hours. The function is to peel off the mica powder into two-dimensional flake mica;

[0043] S2: Put 10 g of glass microspheres into a ball mill and mill at 300 rpm for half an hour. The obtained three-dimensional glass powder is passed through 600 mesh and 800 mesh sieves to obtain three-dimensional glass powder with a particle size between 600 and 800 mesh;

[0044] S3: Weigh 6.6g of two-dimensional flaky mica, 6.6g of three-dimensional glass powder and 20g of dicyandiamide into 20mL of deionized water to obtain a mixture. The mass percentages of each component in the mixture in the total mixture are: 2 Dimensional flaky mica 20%, three-dimensional glass powder 20%, ure...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com