Highly active ruthenium-carbon catalyst modified by transition metal atoms and preparation method thereof

A technology of ruthenium-carbon catalyst and transition metal, which is applied in the field of high-activity ruthenium-carbon catalyst and its preparation, can solve problems such as failure to meet reaction requirements, high cost, and insufficient activity, and achieve excellent catalytic effect, increased yield, and improved catalytic performance. active effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The preparation method of modified ruthenium carbon catalyst of the present invention comprises the steps:

[0033] (1) active carbon carrier and ruthenium solution are mixed and adsorbed;

[0034] (2) Add a certain amount of transition metal salt solution, and continue to stir and adsorb for 1 to 3 hours;

[0035] (3) adding a reducing agent solution for reduction for 1 to 3 hours;

[0036] (4) After the reaction is finished, filter with suction, wash with deionized water until nearly neutral, and dry to obtain a ruthenium-carbon catalyst modified by a transition metal atom.

[0037] Wherein, in step (1), the ruthenium solution is a soluble ruthenium solution, such as ruthenium chloride, ruthenium sulfate, ruthenium nitrite trinitrate or ruthenium acetate solution. A corresponding amount of ruthenium solution is prepared according to the mass percentage of ruthenium atoms in the catalyst being 3wt%-10wt%.

[0038] In step (2), the transition metal salt solution is p...

Embodiment 1

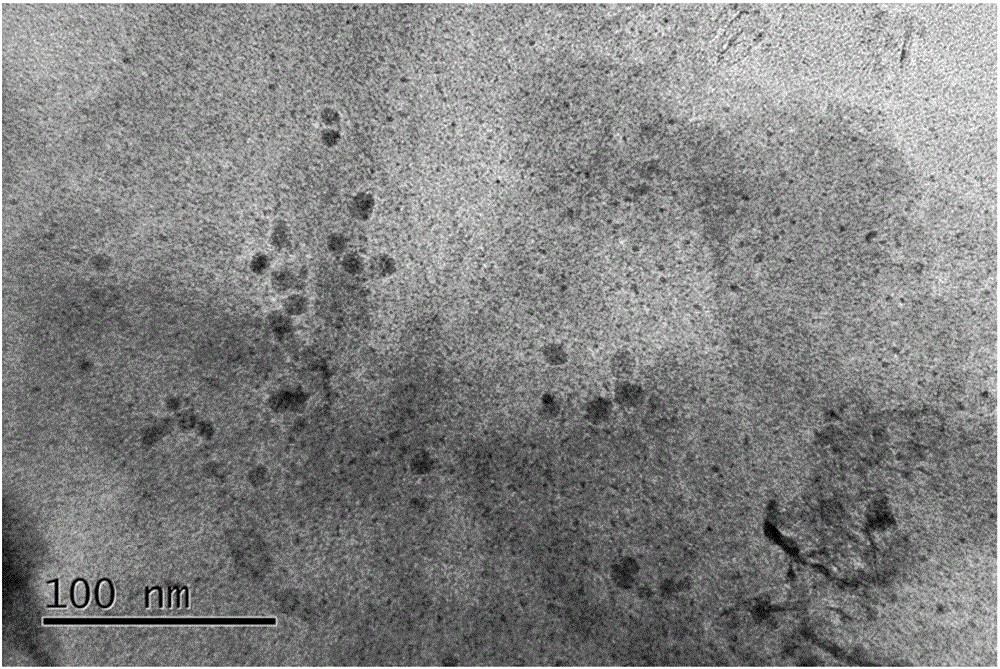

[0044] Preparation of molybdenum atom modified ruthenium carbon catalyst

[0045] Weigh 47.26g of activated carbon powder and disperse it in 200mL of deionized water; weigh 6.723g of ruthenium chloride trihydrate and dissolve it in 100mL of deionized water; under stirring conditions, mix the two and absorb for 1 hour; weigh 1.911g of molybdic acid Ammonium solid ((NH 4 ) 6 Mo 7 o 24 4H 2(0), be dissolved in 50mL deionized water, gradually add in the above-mentioned gac solution under stirring condition; After stirring and absorbing for 1 hour, add sodium borohydride aqueous solution (1.2g sodium borohydride is dissolved in 100mL deionized water) gradually, react 1 at room temperature Hours later, filter with suction, wash 5 times with deionized water to near neutrality, and dry in an oven at 80° C. for 12 hours to obtain a molybdenum atom-modified ruthenium carbon catalyst, wherein the mass percentage of ruthenium is 5 wt%, and the mass percentage of molybdenum The conten...

Embodiment 2

[0048] Preparation of Tungsten Atom Modified Ruthenium Carbon Catalyst

[0049] Weigh 47.26g of activated carbon powder and disperse it in 200mL of deionized water; weigh 6.723g of ruthenium chloride trihydrate and dissolve it in 100mL of deionized water; mix the two under stirring conditions and absorb for 1 hour; weigh 1g of tungsten chloride Solid (WCl 6 ), dissolved in 50mL deionized water, and gradually added to the above activated carbon solution under stirring; after stirring and absorbing for 1 hour, gradually added sodium formate aqueous solution (2g sodium formate dissolved in 100mL deionized water), reacted at 80°C for 1 hour, and suction filtered , washed 5 times with deionized water to near neutrality, and dried in an oven at 80°C for 12 hours to obtain a ruthenium-carbon catalyst modified by tungsten atoms, wherein the mass percentage of ruthenium is 5 wt%, and the mass percentage of tungsten is 0.9 wt%. (Based on the total mass of the catalyst).

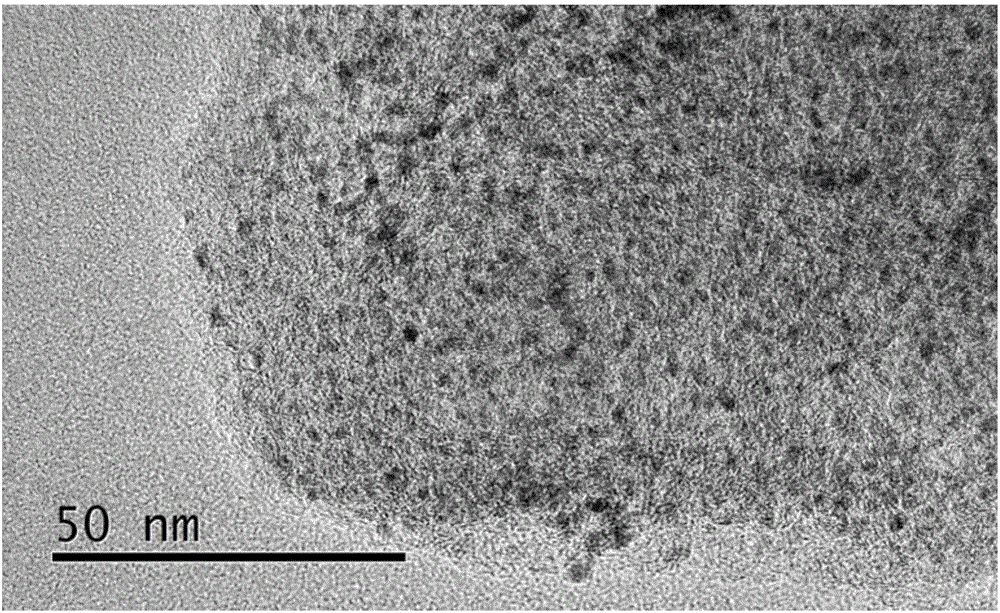

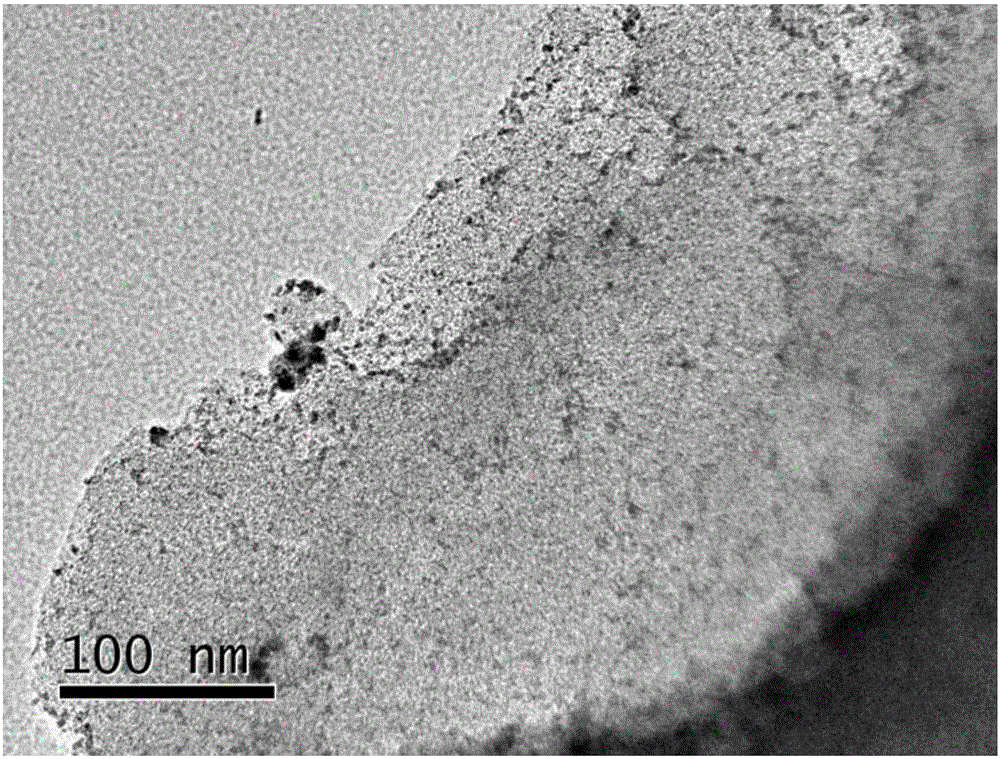

[0050] fig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com