Boiler denitration process taking ammonia-containing waste gas as denitration agent

A technology for denitrification agent and waste gas, which is applied in the separation of dispersed particles, chemical instruments and methods, separation methods, etc., can solve the problems of reducing the investment of denitrification equipment, reducing the cost of denitrification of boilers, and blocking the tail flue, so as to reduce the consumption of latent heat of vaporization. , good economic and environmental benefits, the effect of reducing heat waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Example 1 A boiler denitrification process using ammonia-containing waste gas as a denitrification agent

[0035] The specific steps of the process are as follows:

[0036] (1) In the gasifier, coal and water react under oxygen-enriched conditions to produce a crude process gas that is mainly process gas and contains ammonia as a by-product. The crude process gas enters the carbon scrubber, and in the carbon scrubber remove solid particles;

[0037] (2) The ammonia-containing crude process gas enters the shift furnace after passing through the carbon washing tower, and part of the carbon monoxide and water vapor in the shift furnace are converted into carbon dioxide and hydrogen under the action of the catalyst, and the side reactant ammonia does not participate in the reaction;

[0038] (3) The crude process gas containing ammonia enters the heat exchange system after passing through the shift furnace, and the temperature is lowered in the heat exchange system. The te...

Embodiment 2

[0050] Example 2 A boiler denitrification process using ammonia-containing waste gas as a denitrification agent

[0051] The specific steps of the process are as follows:

[0052] (1) In the gasifier, coal and water react under oxygen-enriched conditions to produce a crude process gas that is mainly process gas and contains ammonia as a by-product. The crude process gas enters the carbon scrubber, and in the carbon scrubber remove solid particles;

[0053] (2) The ammonia-containing crude process gas enters the shift furnace after passing through the carbon washing tower, and part of the carbon monoxide and water vapor in the shift furnace are converted into carbon dioxide and hydrogen under the action of the catalyst, and the side reactant ammonia does not participate in the reaction;

[0054] (3) The crude process gas containing ammonia enters the heat exchange system after passing through the shift furnace, and the temperature is lowered in the heat exchange system. The te...

Embodiment 3

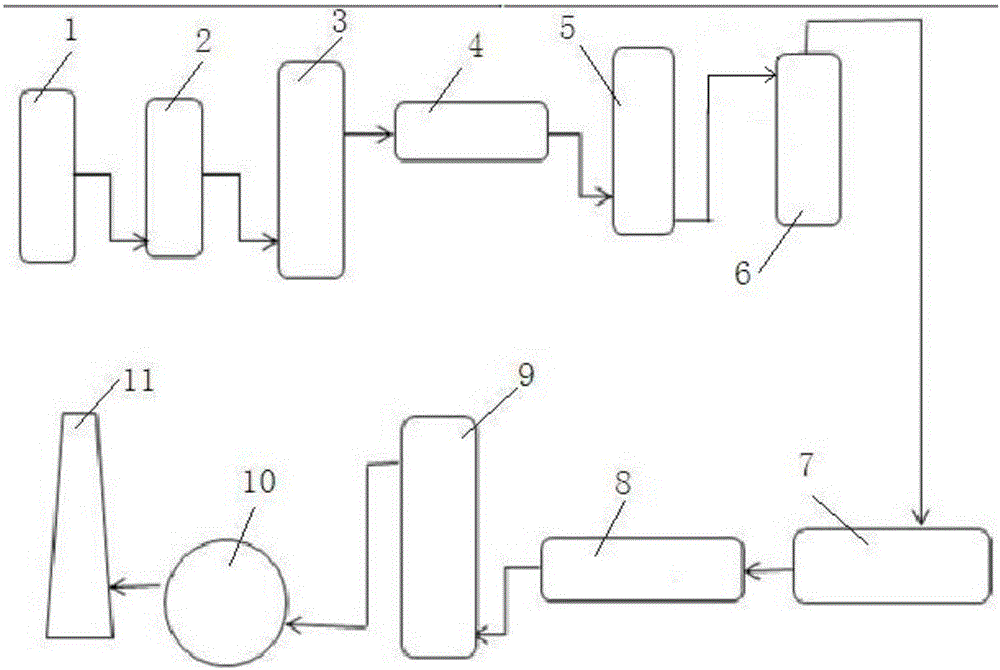

[0067] Example 3 A boiler denitrification system using ammonia-containing waste gas as a denitrification agent, such as figure 1 As shown, the system includes gasification furnace 1, carbon washing tower 2, converter furnace 3, heat exchange system 4, ammonia washing tower 5, stripping tower 6, waste gas mixer 7, boiler air supply system 8, boiler 9, induced draft fan 10 and the chimney 11, the gasifier 1 is connected to the inlet of the carbon scrubber 2 through a pipeline, the outlet of the carbon scrubber 2 is connected to the inlet of the converter 3 through a pipeline, and the outlet of the converter 3 is connected to the inlet of the heat exchange system 4, The outlet of the heat exchange system 4 is connected with the inlet of the ammonia scrubber 5, the ammonia scrubber 5 is provided with a gas outlet and a liquid outlet, the liquid outlet of the ammonia scrubber 5 is connected with the inlet of the stripper 6, and the outlet of the stripper 6 is connected with the The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com