High-protein fermented soybean meal and preparation method thereof

A fermented soybean meal, high-protein technology, applied in the direction of bacteria used in food preparation, food science, animal feed, etc., can solve the problems of reducing nutrient absorption, hindering the combination of nutrients and digestive enzymes, increasing the rate of animal diarrhea, etc., to improve The effect of digesting and absorbing utilization, reducing the content of non-starch polysaccharides, and improving immunity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Mix soybean meal (crushed to 60 mesh) with water at a ratio of 1:0.8, sterilize at 121°C for 20 minutes, add water to a material-water ratio of 1:3, and add a compound enzyme preparation (the amount of α-galactosidase added is 15U / g, β-mannanase, β-glucanase, cellulase, xylanase, pectinase were added at 150U / g each) and placed at 45°C for 4h; Finally, put the sample in a boiling water bath for 20 minutes, add 5wt% Saccharomyces cerevisiae and 5wt% Pediococcus pentosaceae after cooling, separate solid from liquid after semi-solid fermentation for 48h, dry and pulverize.

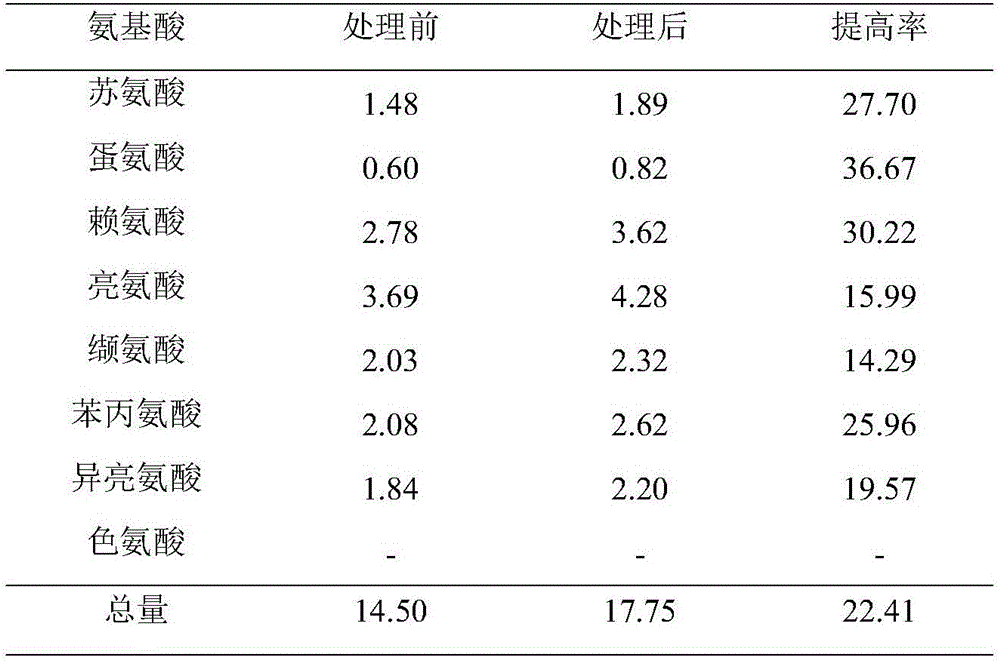

[0033] The soybean meal raw material (blank group) of this example and the product obtained by the method of this example were analyzed for NSP and protein content. The results showed that the NSP of soybean meal decreased from about 25.8% to 7.2%, and the protein content increased from about 46% to 60.6%. The reduction of NSP content could reduce the antinutritional effect of soybean meal and improve ...

Embodiment 2

[0041] Mix soybean meal (crushed to 60 mesh) with water at a ratio of 1:0.8, sterilize at 121°C for 20 minutes, add water to a material-water ratio of 1:2.5, and add a compound enzyme preparation (the amount of α-galactosidase added is 10U / g, β-mannanase, β-glucanase are 150U / g, cellulase, xylanase, pectinase are all added at 200U / g) and placed at 48°C for enzymolysis reaction 3h; after the enzymolysis reaction, place the sample in a boiling water bath for 20min, add 5wt% Saccharomyces cerevisiae and 5wt% Pediococcus pentosaceae after cooling, separate the solid from the liquid after 48h of semi-solid fermentation, dry and pulverize.

[0042] The results show that the NSP content of the fermented soybean meal obtained according to the method of this example is 8.6%, the total protein content is 58.8%, and the polypeptide accounts for 29.1%; the lactic acid content is 2.2%, and the number of viable bacteria reaches 10% 8 CFU / g or more.

Embodiment 3

[0044] Mix soybean meal (crushed to 60 mesh) with water at a ratio of 1:1, sterilize at 121°C for 20 minutes, add water to a material-water ratio of 1:3.5, and add a compound enzyme preparation (the amount of α-galactosidase added is 20U / g, β-mannanase and β-glucanase are both 100U / g, cellulase, xylanase and pectinase are all added at 300U / g) and placed at 35°C for enzymolysis reaction 5h; after the enzymolysis reaction, place the sample in a boiling water bath for 20min, add 5wt% Saccharomyces cerevisiae and 5wt% Pediococcus pentosaceae after cooling, separate the solid from the liquid after 48h of semi-solid fermentation, dry and pulverize.

[0045] The results show that the NSP content of the fermented soybean meal obtained according to the method of this embodiment is 8.5%, the total protein content is 58.3%, and the polypeptide accounts for 27.1%; the lactic acid content is 2.3%, and the number of viable bacteria reaches 10% 8 CFU / g or more.

[0046] Control group 1

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com