A method for extracting tea polyphenols from tea dregs by compound enzyme method

A compound enzyme method and tea residue technology, which is applied in the direction of drug combination, pharmaceutical formula, medical preparations containing active ingredients, etc., can solve the problems that the safety of tea polyphenols cannot be guaranteed, it is not suitable for large-scale production, and the selection of precipitants is high. problem, achieve the effect of avoiding toxic components, low cost and wide application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

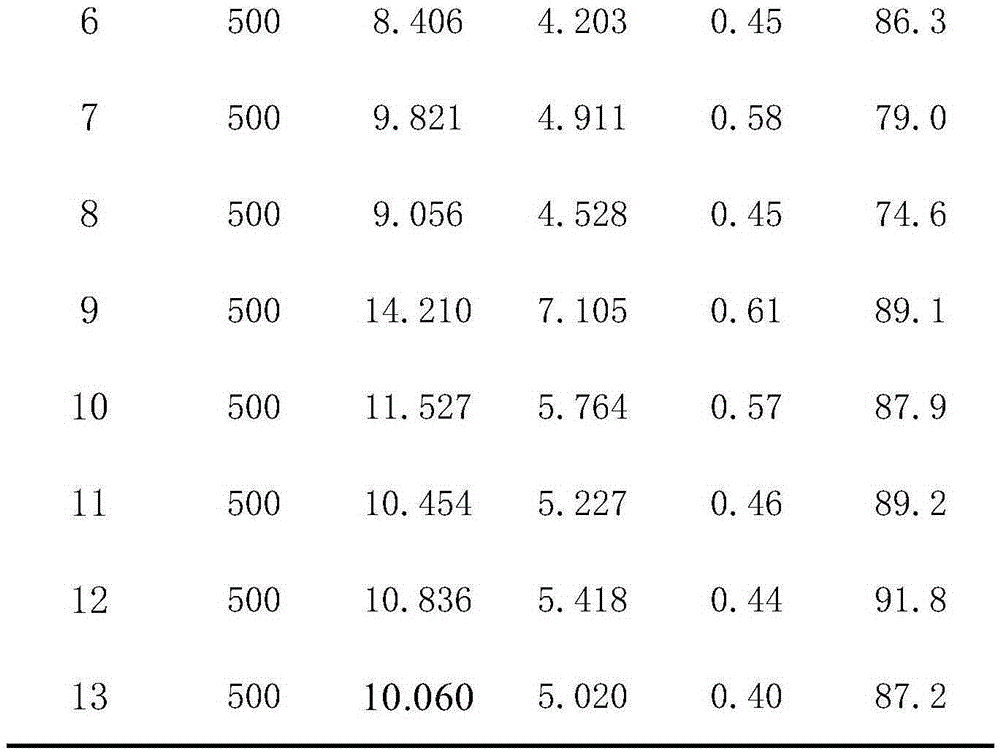

Examples

Embodiment 1

[0027] (1) Take tea Camelliasinensis (L.) O. Kuntzes leaf residue 500g, pulverize.

[0028] (2) Add 3 times the amount of distilled water, soak for 1 hour, and add 1.0 g of pectinase.

[0029] (3) Adjust the pH to 5.6 with HCl, enzymatically hydrolyze at 50°C for 2.5 hours, and then boil for 3 minutes to inactivate the enzyme.

[0030] (4) Add ethanol to make the final concentration of ethanol reach 5% by volume, and extract by heating. The tea leaves were extracted twice with ethanol solution with a final concentration of 5% by volume. The extraction conditions are: temperature 77°C, 1 hour each time. Combine the three extracts, filter the extract, centrifuge, take the supernatant, evaporate under reduced pressure, and the extraction amount is 8.332 mg / g.

[0031] (5) Concentrate the supernatant under reduced pressure to obtain the extract, add water to the extract until it is completely dissolved, slowly add the above extract to the AB-8 macroporous adsorption resin, adju...

Embodiment 2

[0034] (1) Take 500g of tealeaves Camelliasinensis (L.) O. Kuntze slag and crush them.

[0035] (2) Add 3 times the amount of distilled water, soak for 1 hour, and add 1.5g of pectinase.

[0036] (3) Adjust the pH to 5.6 with HCl, enzymatically hydrolyze at 50°C for 2.5 hours, and then boil for 3 minutes to inactivate the enzyme.

[0037] (4) Add ethanol to make the final concentration of ethanol reach 5% by volume, and extract by heating. The tea leaves were extracted twice with ethanol solution with a final concentration of 5% by volume. The extraction conditions are: temperature 77°C, 1 hour each time. Combine the extracts for three times, filter the extracts, centrifuge, take the supernatant, evaporate under reduced pressure, and the extraction amount is 7.865mg / g.

[0038] (5) Concentrate the supernatant under reduced pressure to obtain the extract, add water to the extract until it is completely dissolved, slowly add the above extract to AB-8 macroporous adsorption re...

Embodiment 3

[0041] (1) Take 500g of tealeaves Camelliasinensis (L.) O. Kuntze slag and crush them.

[0042] (2) Add 3 times the amount of distilled water, soak for 1 hour, and add 2.0g of pectinase.

[0043] (3) Adjust the pH to 5.6 with HCl, enzymatically hydrolyze at 50°C for 2.5 hours, and then boil for 3 minutes to inactivate the enzyme.

[0044] (4) Add ethanol to make the final concentration of ethanol reach 5% by volume, and extract by heating. The tea leaves were extracted twice with ethanol solution with a final concentration of 5% by volume. The extraction conditions are: temperature 75°C, 1 hour each time. Combine the extracts for three times, filter the extracts, centrifuge, take the supernatant, evaporate under reduced pressure, and the extraction amount is 7.241 mg / g.

[0045] (5) Concentrate the supernatant under reduced pressure to obtain the extract, add water to the extract until it is completely dissolved, slowly add the above extract to LX-60 macroporous adsorption ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com