Liquid crystal display element, liquid crystal alignment film, and liquid crystal alignment treatment agent

A liquid crystal alignment film, liquid crystal alignment technology, applied in the direction of liquid crystal materials, chemical instruments and methods, instruments, etc., can solve the problems of increased power consumption, etc., and achieve the effect of good scattering characteristics, good optical characteristics, and high adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

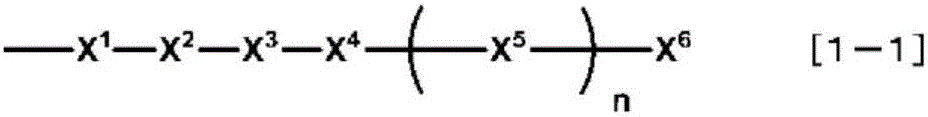

[0278] Examples are listed below to further describe the present invention in detail, but the present invention is not limited to them. The abbreviations used below are as follows.

[0279] (liquid crystal)

[0280] L1: MLC-6608 (manufactured by MERCK CORPORATION)

[0281] (polymeric compound)

[0282]

[0283] (photopolymerization initiator)

[0284]

[0285] (first side chain type diamine)

[0286] A1: 1,3-diamino-4-[4-(trans-4-n-heptylcyclohexyl)phenoxy]benzene

[0287] A2: 1,3-diamino-4-[4-(trans-4-n-heptylcyclohexyl)phenoxymethyl]benzene

[0288] A3: 1,3-diamino-4-{4-[trans-4-(trans-4-n-pentylcyclohexyl)cyclohexyl]phenoxy}benzene

[0289] A4: Diamine represented by the following formula [A4]

[0290] A5: 1,3-diamino-4-octadecyloxybenzene

[0291]

[0292] (second side chain type diamine)

[0293]

[0294] (other diamines)

[0295] C1: m-phenylenediamine

[0296] C2: 3,5-diaminobenzoic acid

[0297]

[0298] (tetracarboxylic acid)

[0299] D1: 1...

Synthetic example 1

[0329] D2 (5.74g, 23.0mmol), A1 (7.08g, 18.6mmol), B1 (2.46g, 9.30mmol) and C2 (0.47g, 3.10mmol) were mixed in NMP (34.5g) and reacted at 50°C for 8 After one hour, D1 (1.50g, 7.65mmol) and NMP (17.3g) were added, it was made to react at 40 degreeC for 8 hours, and the polyamic-acid solution (1) whose resin solid content concentration was 25 mass % was obtained. The number average molecular weight of this polyamic acid was 21,600, and the weight average molecular weight was 67,800.

Synthetic example 2

[0331] After adding NMP to the polyamic acid solution (1) (30.0g) obtained by the synthesis example 1 and diluting to 6 mass %, acetic anhydride (3.15g) and pyridine (2.40g) were added as an imidation catalyst, The reaction was carried out at 50° C. for 3 hours. This reaction solution was poured into methanol (460 ml), and the obtained precipitate was collected by filtration. This deposit was wash|cleaned with methanol, and it dried under reduced pressure at 60 degreeC, and obtained the polyimide powder (2). The imidization rate of this polyimide was 55%, the number average molecular weight was 17,800, and the weight average molecular weight was 49,100.

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com