Absorbing articles comprising water absorbing resin and method for producing the same

A technology of water-absorbent resin and absorbent products, applied in absorbent pads, bandages, medical science, etc., to achieve the effect of high elastic modulus and high swelling capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

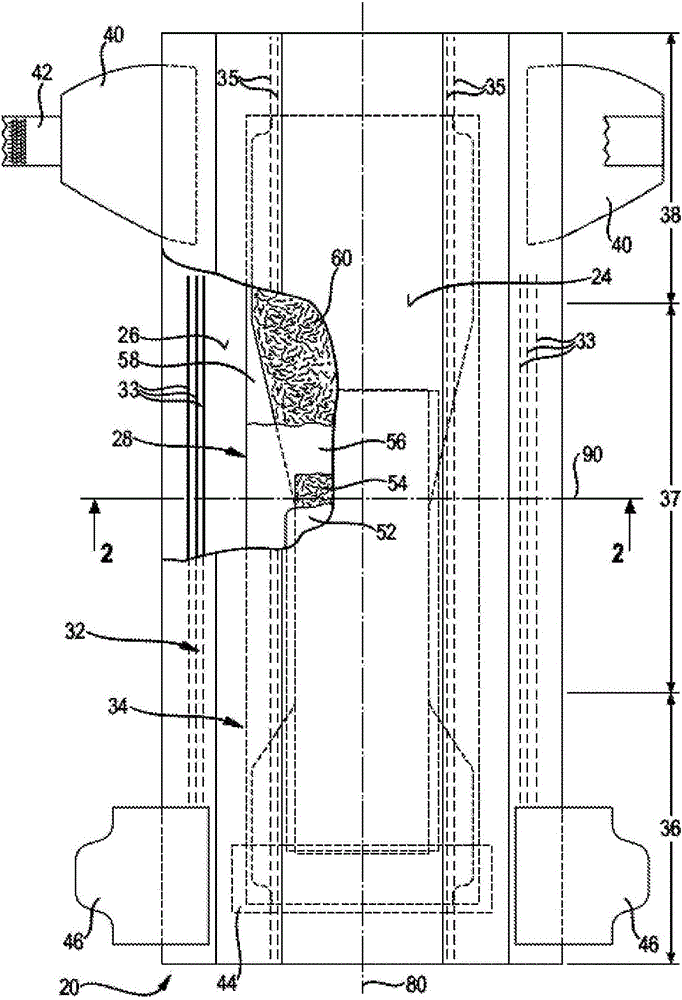

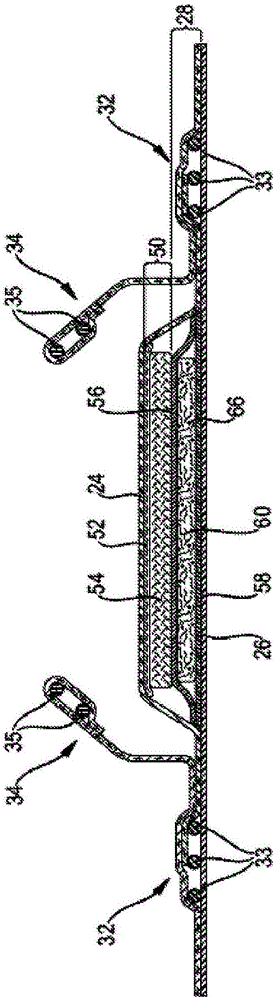

Image

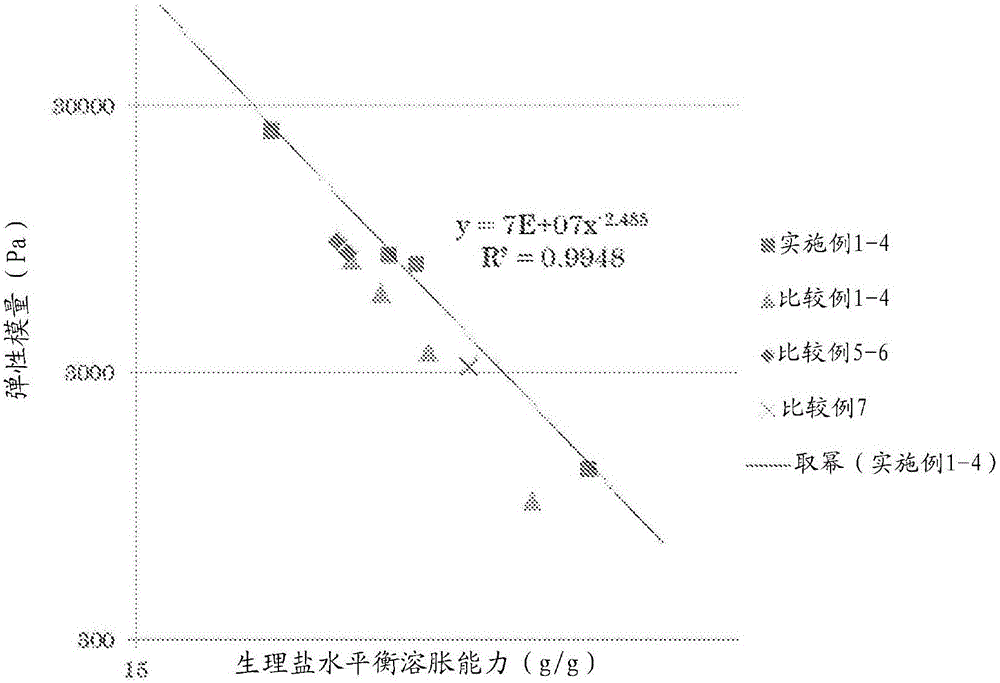

Examples

preparation example Construction

[0086] As described above, the reaction step of the production method is preferably carried out in a state where the dissociable group of the water-soluble unsaturated monomer forming the first star polymer and the second star polymer is protected by a protecting group. Branches of binary star polymers (and tertiary, quaternary, ... star polymers). In this case, generally, after the completion of the reaction step, a step of deprotecting the cleavable group is also included. For example, in the case where a tert-butyl group is used as a protecting group for a carboxyl group serving as a dissociable group, the carboxyl group serving as a dissociable group is made is released, and thus a water-absorbent resin including a water-soluble unsaturated monomer having a dissociable group such as acrylic acid as a main composition in the repeating unit of the main chain and having an internally crosslinked structure can be obtained.

[0087] A neutralization step is performed on the th...

Embodiment 1

[0192] (Synthesis of four-armed star core)

[0193] The four-armed star core having the chemical structure represented by the following chemical formula A is described in Scheme 1 (page 14601) of the prior art document (J.Am.Chem.Soc., 2006, 128, 14599-14605) method synthesis.

[0194] [chemical formula A]

[0195] Four Arm Star Core

[0196]

[0197] (Synthesis of Four-Armed Star Polymer (1-Br))

[0198] In a 50 ml recovery flask with a stirrer in it and filled with nitrogen, 80 mg of copper (I) bromide and 6 mg of copper (II) bromide were dissolved in 2.0 g of acetone and 14.1 g of tert-butyl acrylate. 107 mg of pentamethyldiethylenetriamine was added thereto, and the mixture was stirred at room temperature for 5 minutes. Then, 0.2 g of the four-arm star core synthesized above was added to the mixture to prepare a reaction solution. The reaction solution was stirred for 1.5 hours in an oil bath at a temperature of 50° C. while heating. The obtained solution wa...

Embodiment 2

[0240] (Synthesis of Four-Armed Star Polymer (2-Br))

[0241] Obtain the solid four-armed star-shaped polymer (2-Br) having the chemical structure (n=30) in the above chemical formula B in the same manner as "the synthesis of the four-armed star-shaped polymer (1-Br)" in Example 1 , except that the amount of tert-butyl acrylate was set to 17.6 g and the reaction time was set to 2 h.

[0242] (four-armed star polymer (2-N 3 )Synthesis)

[0243] According to " four-arm star polymer (1-N) in embodiment 1 3 ) in the same manner to obtain the solid four-arm star polymer (2-N) with chemical structure (n=30) in the above chemical formula C 3 ), the difference is that the above-synthesized four-arm star polymer (2-Br) is used instead of the four-arm star polymer (1-Br) and sodium azide (NaN 3 ) amount is set to 110 mg.

[0244] The thus obtained four-armed star polymer (2-N 3 ) had a weight average molecular weight Mw of 17,029, and a molecular weight distribution Mw / Mn th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com