Fluxgate sensor chip

A fluxgate sensor and chip technology, applied in instruments, measuring magnetic variables, measuring devices, etc., can solve the problems of difficulty in reducing the size of the fluxgate sensor, sensor damage, etc., to avoid chemical mechanical polishing process, reduce noise and energy consumption, the effect of improving signal response speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The idea, specific structure and technical effects of the present invention will be further described below in conjunction with the accompanying drawings, so as to fully understand the purpose, features and effects of the present invention.

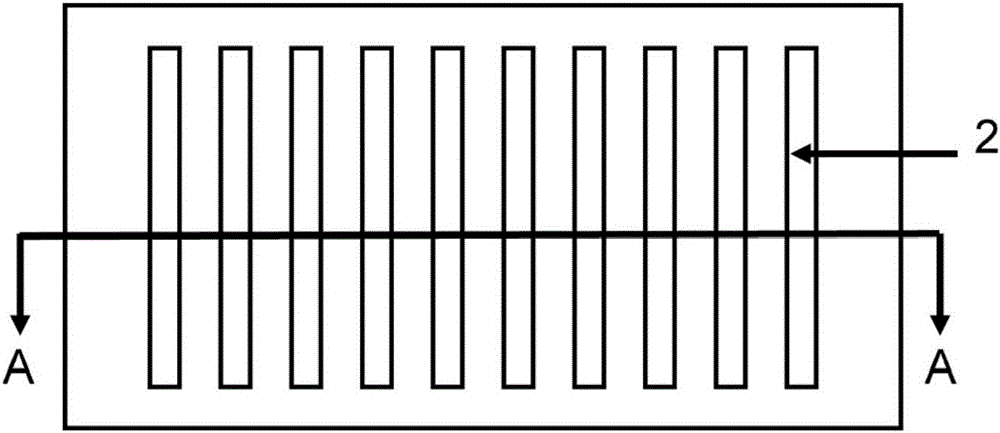

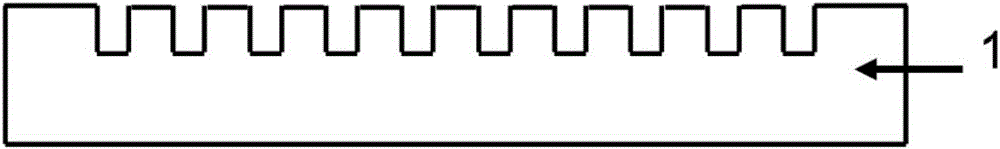

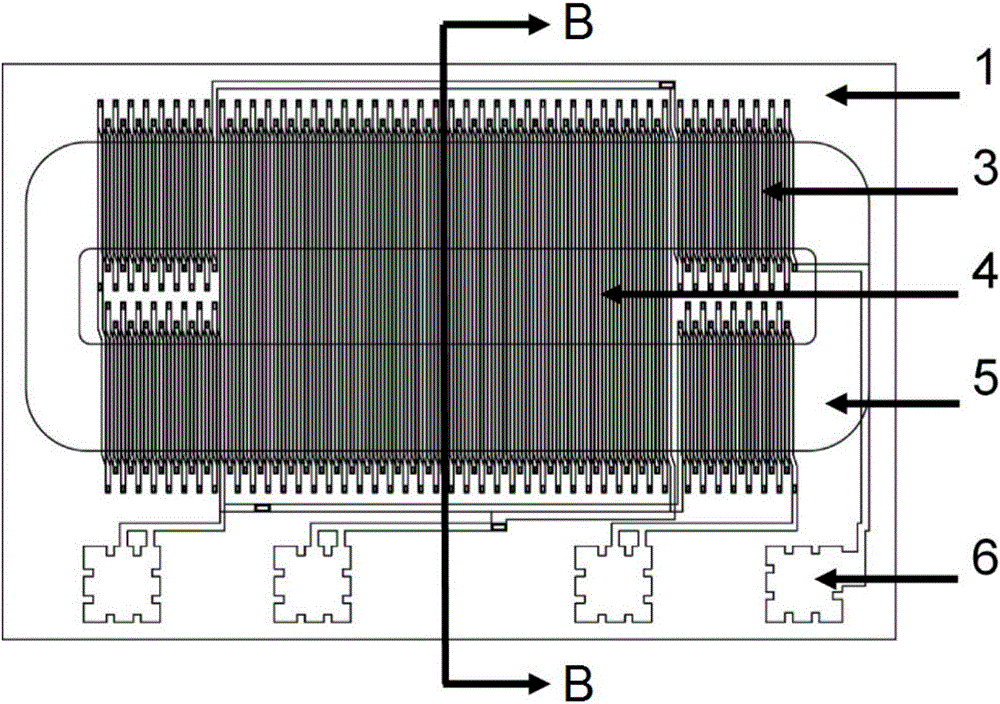

[0031] like Figure 1-3 As shown, the fluxgate sensor chip using silicon dioxide film insulation coating of the present invention includes a high-resistance silicon substrate 1, an excitation coil 2, a detection coil 3, a magnetic core 4, electrodes 5 and a silicon dioxide film 6, wherein Both the excitation coil and the detection coil are micro-electromechanical three-dimensional solenoid coils, the bottom coils of the excitation coil and the detection coil are located in the silicon microgroove array 7 on the surface of the high-resistance silicon substrate, and the upper surface of the bottom coil is flush with the surface of the silicon substrate. The wire width and gap of the bottom coil and the top coil of the excitation coil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com