A kind of anti-blue light antimagnetic thin film and preparation method thereof

An anti-blue light and film technology, applied in the direction of film/sheet adhesive, coating, non-polymer organic compound adhesive, etc., to achieve the effect of protecting electromagnetic interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

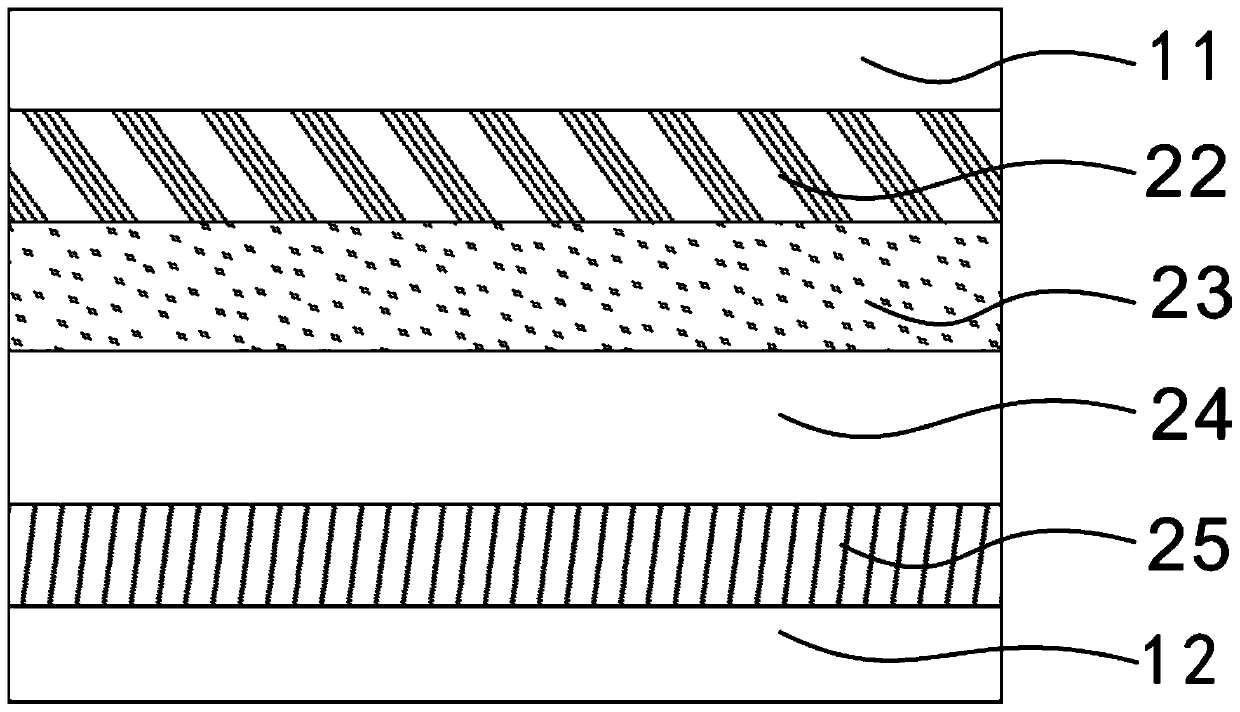

[0056] The anti-blue light and anti-magnetic film structure includes an insulating substrate 24, an acrylic adhesive layer 25, a diamagnetic metal layer 23, an anti-blue light layer 22 and a release film (upper release film 11, lower release film 12).

[0057] The specific preparation steps are as follows:

[0058] The diamagnetic metal layer 23 is placed on the carrier insulating substrate 24, coated with a doctor blade, and cured in an oven at 150° C. for 2 minutes to form the diamagnetic metal layer 23 .

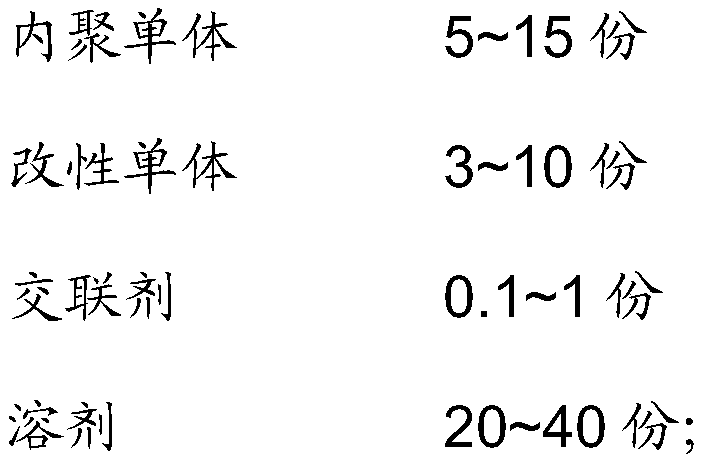

[0059] The components of the diamagnetic metal layer 23 are: 100 parts of resin, 10 parts of diamagnetic metal material, and a thickness of 75 μm.

[0060] Among them, the resin is preferably an acrylic resin. The diamagnetic metal material is silver-gold powder. The diameter of silver metal particles is not more than 10 μm.

[0061] The anti-blue light layer 22 is coated on the coated diamagnetic metal layer 23, coated with a doctor blade, and cured in an oven at 160°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com