Acetylacetone metal component, precreation method for acetylacetone metal component, plastic and application of heat stabilizer

A technology of acetylacetone and its composition, which is applied in the field of polyvinyl chloride, acetylacetone metal composition and its preparation, can solve the problems of pollution, heat stabilizer toxicity, etc., and achieve the effect of weakening the characteristic odor, increasing the dosage, and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

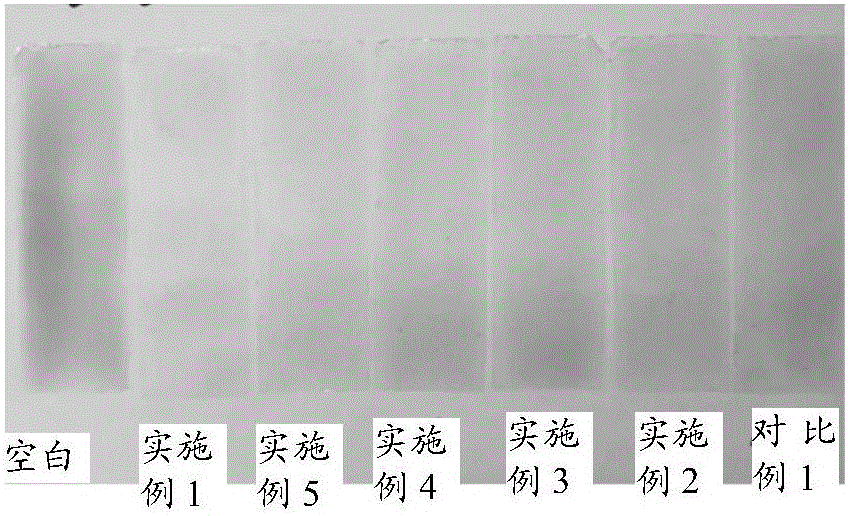

Examples

Embodiment 1

[0063] Add 37g of calcium hydroxide into a three-necked flask equipped with methanol solvent, put it on an iron stand and stir, then add dropwise the acetylacetone solution containing 100g of acetylacetone dry weight, the reaction temperature is 25°C, and stir for 1 hour to react. Then, 37 g of calcium hydroxide was added to the reaction system, the reaction temperature was maintained at 25° C., and the stirring reaction was continued for 1 hour. The molar ratio of the total amount of calcium hydroxide used to acetylacetone is 1:1.

[0064] After the reaction, filter the reaction product with suction, and use the obtained filtrate for later use. Then weigh the filter cake and dry it in an oven at 105°C. After drying, it is pulverized to obtain the acetylacetone-calcium composition, and then weigh the obtained product to calculate The yield is 94.87%. The characteristic odor of the acetylacetonate-calcium composition obtained in this example is weakened.

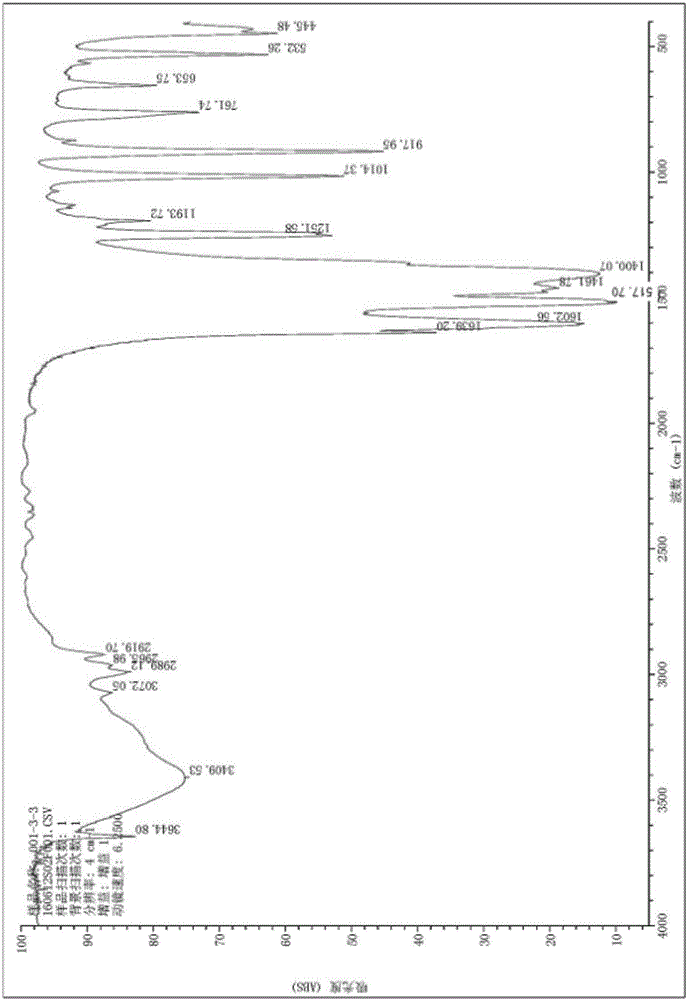

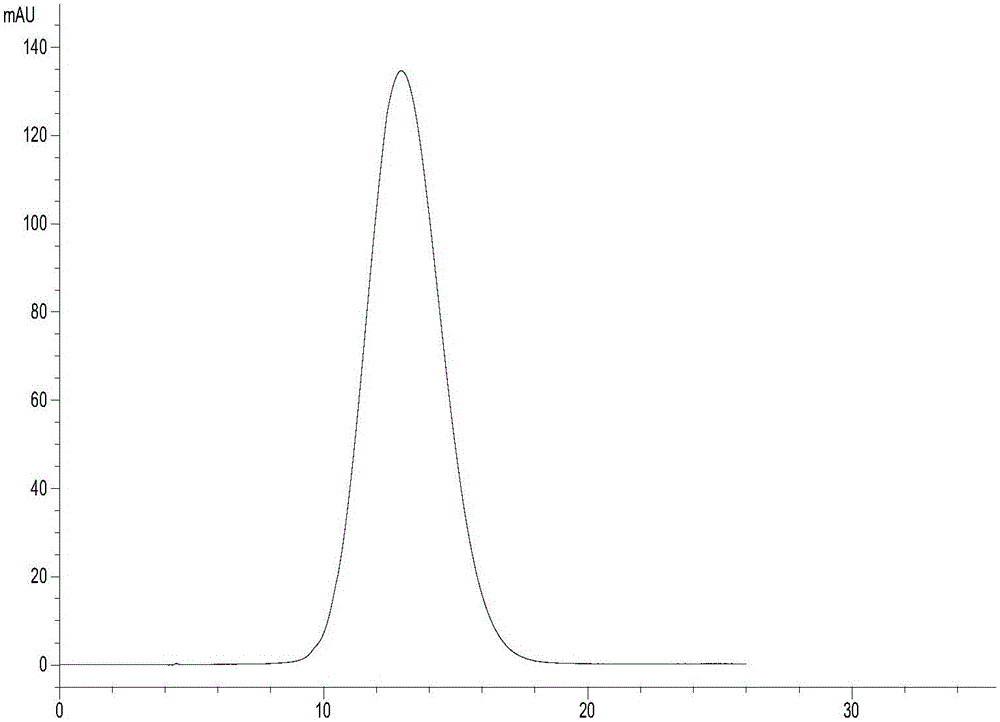

[0065] The calcium ...

Embodiment 2

[0103] Add 37g of calcium hydroxide into a three-necked flask filled with water, place it on an iron stand and stir, then add dropwise an acetylacetone solution containing 180g of acetylacetone dry weight, the reaction temperature is 20°C, and stir for 0.25 hours. Then, 37 g of calcium hydroxide was added to the reaction system, the reaction temperature was maintained at 20° C., and the stirring reaction was continued for 0.25 hours. The molar ratio of calcium hydroxide and acetylacetone used is 1:1.8.

[0104] After the reaction, filter the reaction product with suction, and use the obtained filtrate for later use. Then weigh the filter cake and dry it in an oven at 105°C. After drying, it is pulverized to obtain the acetylacetone-calcium composition, and then weigh the obtained product to calculate The yield is 96.46%. The characteristic odor of the acetylacetonate-calcium composition obtained in this example is weakened.

[0105] The obtained product was analyzed for acet...

Embodiment 3

[0108] Add 37g of calcium hydroxide to a three-necked flask filled with methanol, stir on an iron stand, then dropwise add acetylacetone solution containing 160g dry weight of acetylacetone, the reaction temperature is 30°C, and stir for 0.5 hours. Then, 37 g of calcium hydroxide was added into the reaction system, the reaction temperature was maintained at 30° C., and the stirring reaction was continued for 0.5 hours. The molar ratio of calcium hydroxide and acetylacetone used is 1:1.6.

[0109] After the reaction, filter the reaction product with suction, and use the obtained filtrate for later use. Then weigh the filter cake and dry it in an oven at 105°C. After drying, it is pulverized to obtain the acetylacetone-calcium composition, and then weigh the obtained product to calculate The yield is 96.06%. The characteristic odor of the acetylacetonate-calcium composition obtained in this example is weakened.

[0110] The obtained product was analyzed for acetylacetone conte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com