Diatom ooze material containing basalt fiber and preparation method of diatom ooze material

A technology of basalt fiber and diatom mud, which is applied in the field of environmentally friendly building interior wall materials, can solve problems such as not being able to be used alone, insufficient reinforcement effect, easy powder removal, etc., to achieve improved bonding strength, low-cost raw materials, environmental protection, and easy operation. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

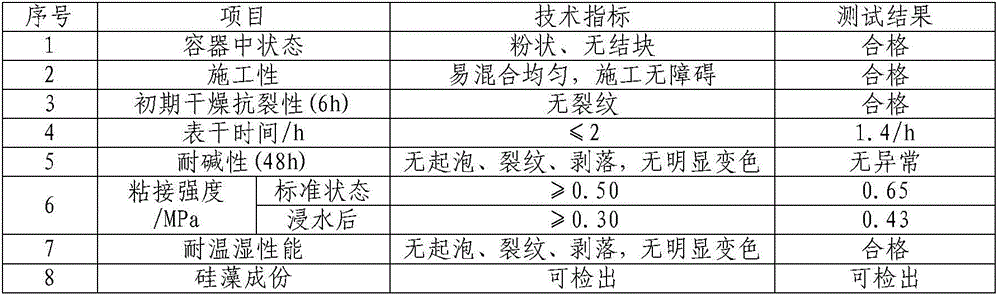

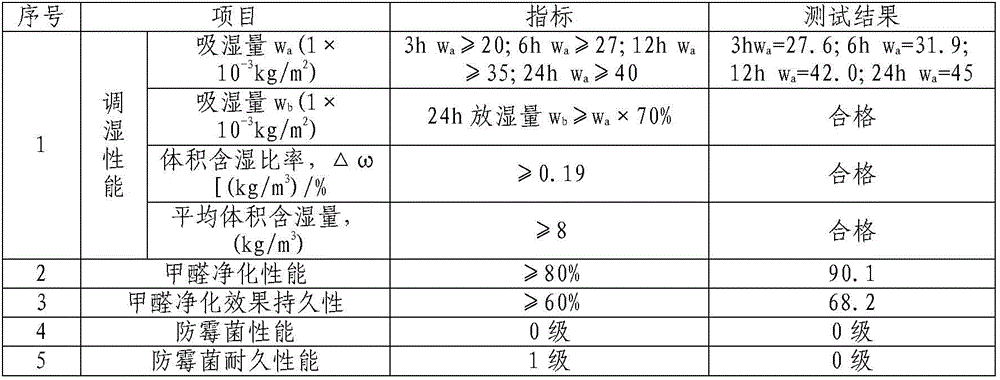

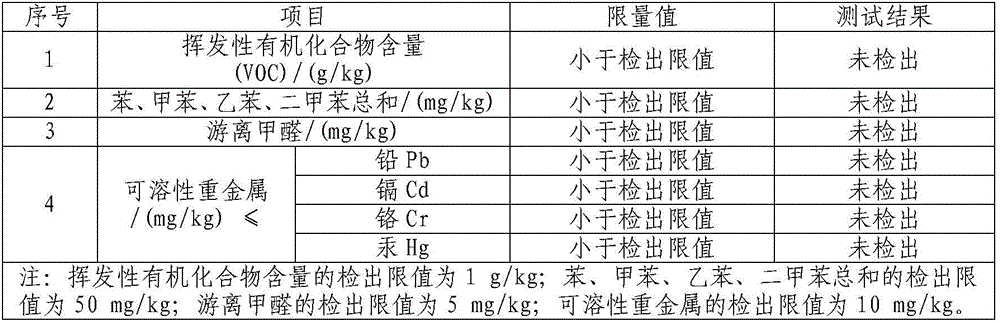

Examples

Embodiment 1

[0021] The present invention adopts pregelatinized starch, a pure natural plant green adhesive that is instant in cold water, high in bonding strength, cheap and good in quality, and compounded with cellulose ether to obtain a new type of inorganic gelling system; at the same time, basalt fiber is selected as the reinforcing fiber, Harmless to the human body, it is a green and environmentally friendly pure natural mineral fiber. It has good stability, chemical corrosion resistance, mechanical properties, anti-aging properties, good dispersion properties, tensile strength up to 2500MPa, elastic modulus up to 90GPa, interfacial adsorption adhesion and mechanical meshing between fiber and diatom mud substrate Force, etc. increase the crack resistance of the material, and the fiber can disperse the energy of thermal contraction and expansion of the wall, and enhance the toughness of the wall material. Moreover, the cost of basalt fiber is lower than that of lignin fiber, which is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com