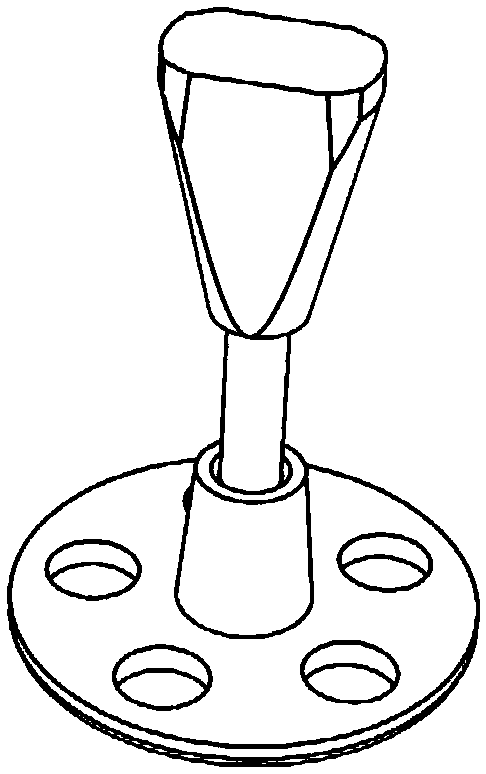

A kind of passive middle ear implant device and preparation method thereof

A technology of ear implants and material pellets, applied in the field of biomedical engineering, can solve problems such as high cost and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] The forming mold adopts a two-plate mold and a four-cavity structure. The temperature of the mold temperature controller is set at 50°C. The mold adopts a needle-valve hot runner and a vacuum pumping interface auxiliary facility. The gate is located at the outer edge of the disc.

[0063] (1) The D50 of pure titanium powder in the injection material is 16 μm, and the purity meets the chemical composition requirements of the first-grade pure titanium. The volume percentage of pure titanium powder is 60%, and the binder is PEG5000+PMMA95000+SA. The volume percentage of each component in the formula is: PEG5000 86.8%, PMMA95000 10.5%, SA 2.7%, the binder accounts for 40% of the volume percent of the injection material; the above pure titanium powder and binder are placed under an argon protective atmosphere In a blender, heat to 160°C, and after mixing evenly, use granulation equipment to make injection granules with a diameter of about 3mm.

[0064] (2) Put the above-ment...

Embodiment 2

[0071] The forming mold adopts a two-plate mold and a four-cavity structure. The temperature of the mold temperature controller is set at 52°C. The mold adopts a needle-valve hot runner and a vacuum pumping interface auxiliary facility. The gate is located at the outer edge of the disc.

[0072] (1) Pure titanium powder D in the injection material 50 The purity is 5 μm, and the purity meets the chemical composition requirements of first-grade pure titanium. The volume percentage of pure titanium powder is 60%, the binder is PEG7000+PMMA75000+SA, and the volume percentage between the components of the binder is PEG7000 84.8%, PMMA75000 12.5% %, SA 2.7%, the volume percentage of binder is 40%. Put the above pure titanium powder and binder in a mixer under an argon protective atmosphere, heat to 175°C, and after mixing evenly, use granulation equipment to make injection granules with a diameter of about 3mm.

[0073] (2) Put the above-mentioned injection material into the hopper...

Embodiment 3

[0080] The forming mold adopts a two-plate mold and a four-cavity structure. The temperature of the mold temperature controller is set at 40°C. The mold adopts a needle valve type hot runner and a vacuum pumping interface auxiliary facility. The gate is located at the outer edge of the disc.

[0081] (1) Pure titanium powder D in the injection material 50The purity is 25 μm, and the purity meets the chemical composition requirements of the first-grade pure titanium. The volume percentage of pure titanium powder is 64%, the binder is PEG5000+PMMA95000+SA, and the volume percentage between the components of the binder is PEG5000 86.8%, PMMA95000 10.5 %SA 2.7%, the volume percentage of binder is 36%. Put the above pure titanium powder and binder in a mixer under an argon protective atmosphere, heat to 150°C, and after mixing evenly, use granulation equipment to make injection granules with a diameter of about 3mm.

[0082] (2) Put the above-mentioned injection material into the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

| ultimate tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com