Ultra-high-strength aluminum alloy composite strip for radiator of automobile water tank and manufacturing method thereof

An ultra-high-strength, automobile water tank technology, applied in the field of aluminum alloy composite strip and its manufacturing, can solve the problems of low yield strength, complex brazing process of Mg-containing aluminum alloy, and unsuitable for manufacturing automobile water tank radiators, etc. Effects of mechanical properties, increased cost and process complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

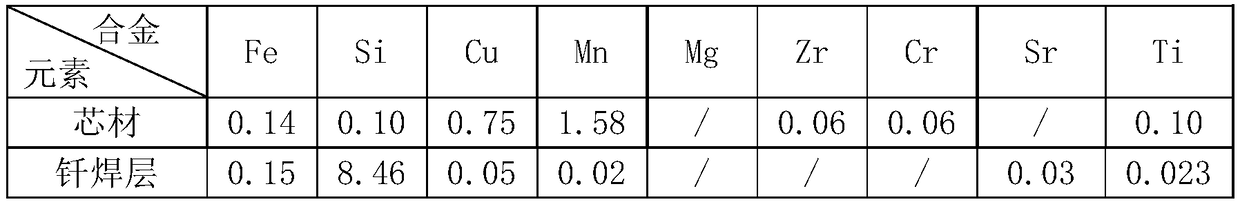

[0029] (1) Put the raw materials prepared according to the composition percentages in the table below into the smelting furnace. When the core material is smelted, the melt temperature is 740°C, the refining temperature in the standing furnace is 745°C, and the refining time is 15 minutes; the brazing layer is smelted Al-Sr master alloy modification agent, the modification temperature is 760°C, after electromagnetic stirring, let stand for 15 minutes and pour the furnace, the refining temperature in the standing furnace is 740°C, and the refining time is 20 minutes; the chemical composition of the core material and brazing layer is shown in the table below .

[0030]

[0031] (2) The casting process parameters are controlled as follows: the casting temperature of the core material is 705°C, the casting speed is 43mm / min, and the cooling water flow rate is 310m 3 / h, the ingot length is 6000mm; the casting temperature of the brazing layer is 690°C, the casting speed is 52mm / ...

Embodiment 2

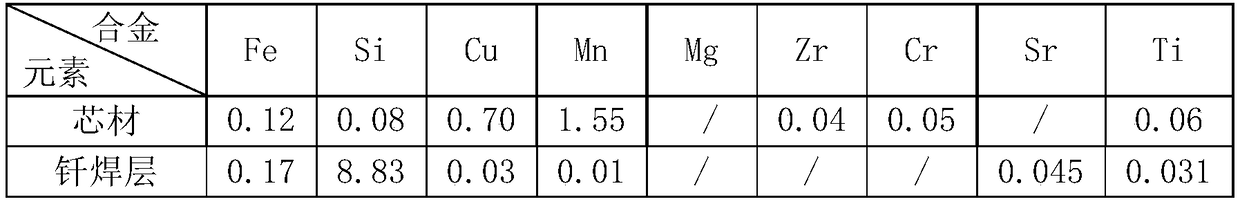

[0042] (1) Put the raw materials prepared according to the composition percentages in the table below into the smelting furnace. When the core material is smelted, the melt temperature is 760°C, the refining temperature in the standing furnace is 760°C, and the refining time is 15 minutes; the brazing layer is smelted Al-Sr master alloy modification agent, the modification temperature is 760°C, after electromagnetic stirring, stand still for 15 minutes and turn the furnace back, the refining temperature in the standing furnace is 745°C, and the refining time is 20 minutes; the chemical composition of the core material and brazing layer is shown in the table below .

[0043]

[0044](2) The casting process parameters are controlled as follows: the casting temperature of the core material is 700°C, the casting speed is 41mm / min, and the cooling water flow rate is 300m 3 / h, the ingot length is 6000mm; the casting temperature of the brazing layer is 695°C, the casting speed is...

Embodiment 3

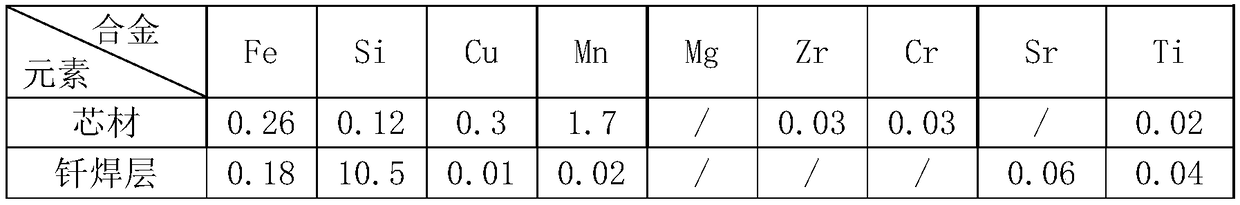

[0055] (1) Put the raw materials prepared according to the composition percentages in the table below into the smelting furnace. When the core material is smelted, the melt temperature is 740°C, the refining temperature in the standing furnace is 740°C, and the refining time is 15 minutes; the brazing layer is smelted Al-Sr master alloy modification agent, the modification temperature is 760°C, after electromagnetic stirring, stand still for 15 minutes and pour the furnace, the refining temperature in the standing furnace is 760°C, and the refining time is 20 minutes; the chemical composition of the core material and brazing layer is shown in the table below .

[0056]

[0057] (2) The casting process parameters are controlled as follows: the casting temperature of the core material is 710°C, the casting speed is 43mm / min, and the cooling water flow rate is 310m 3 / h, the ingot length is 6000mm; the casting temperature of the brazing layer is 690°C, the casting speed is 52m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com