Porous core-shell structure negative electrode material, preparation method and battery thereof

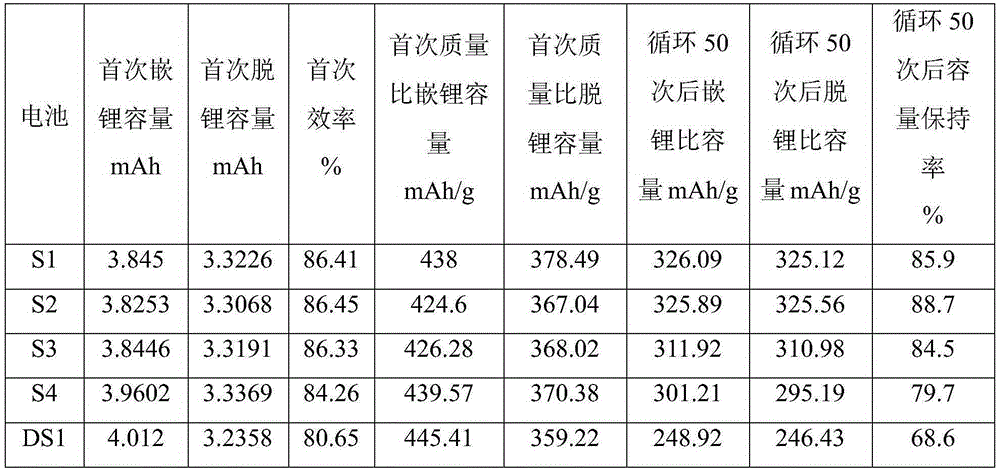

A negative electrode material and porous structure technology, applied in the field of porous core-shell structure negative electrode materials and their preparation and batteries, can solve the problems of volume expansion, difficulty in obtaining electric cycle performance of batteries, etc., and achieve good cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The invention provides a method for preparing a negative electrode material with a porous core-shell structure, wherein the method comprises:

[0029] (1) Disperse calcium carbonate and / or calcium oxalate and at least one carbonaceous material selected from graphite, hard carbon and soft carbon in a solution containing cobalt compounds and tin compounds to prepare a dispersion and introduce a precipitant Carry out precipitation, then carry out solid-liquid separation, obtain the first solid phase;

[0030] (2) dispersing the first solid phase in a solution containing a carbon source material, and then removing the solvent to obtain a second solid phase;

[0031] (3) Under an inert atmosphere, subjecting the second solid phase to pyrolysis treatment.

[0032] According to the present invention, step (1) disperses calcium carbonate and / or calcium oxalate and at least one carbonaceous material selected from graphite, hard carbon and soft carbon in a solution containing a ...

Embodiment 1

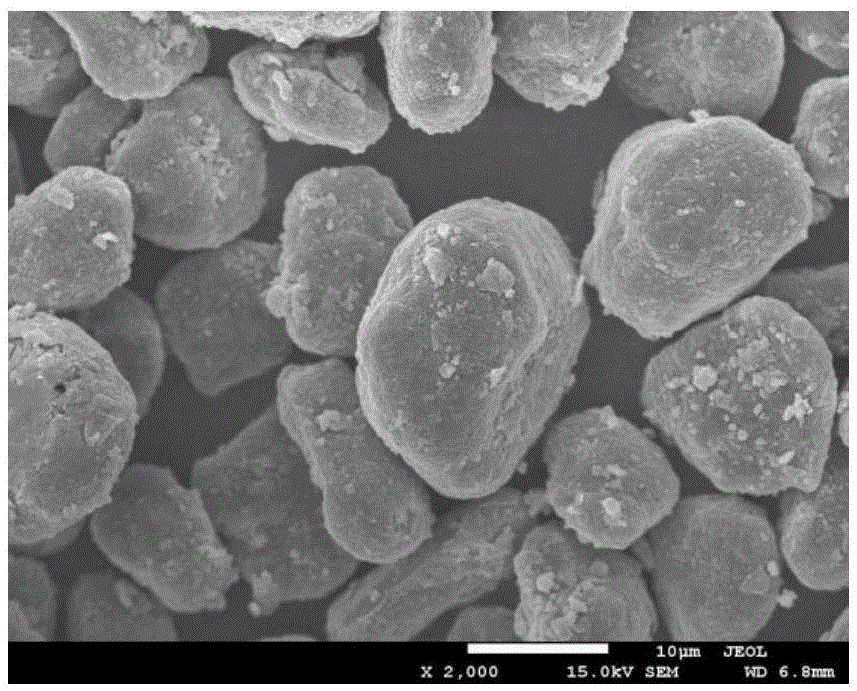

[0072] This example is used to illustrate the negative electrode material with porous core-shell structure of the present invention and its preparation method.

[0073] (1) 5g polyvinylpyrrolidone (purchased from Sinopharm Group Chemical Reagent Co., Ltd. K-30 brand) is added to the aqueous solution of cobalt chloride and stannous sulfate (300g, wherein, the content of cobalt chloride is 1.8% by weight, sulfuric acid The content of stannous is 4.8% by weight), after stirring the solvent, add the nano-calcium carbonate particle (particle diameter is 50nm, purchased from Shenzhen Puli Chemical Materials Co., Ltd., hereinafter the same) and 50g of spherical graphite particle (particle diameter is 50nm) of 1g 11 μm, purchased from Qingdao Taihelong New Energy Materials Co., Ltd. NG_21 grade), and put the mixture into a nodular ink tank (using a zirconium ball with a diameter of 10 mm) and ball mill it at a speed of 50 rpm for 1 hour to obtain a dispersion; use a metering pump to di...

Embodiment 2

[0078] This example is used to illustrate the negative electrode material with porous core-shell structure of the present invention and its preparation method.

[0079] According to the method described in embodiment 1, the difference is:

[0080] The consumption of calcium carbonate is 0.5g in the step (1);

[0081] In step (2), the high-temperature coal tar pitch was replaced with 15 g of glucose, and naphthalene was replaced with 200 mL of deionized water, and 0.3 g of carbon nanotubes (purchased from Tiannai Material Technology Co., Ltd. LB200 brand) were added;

[0082] In the second heating stage in step (3), the temperature can be raised to 750° C. at a rate of 10° C. / min.

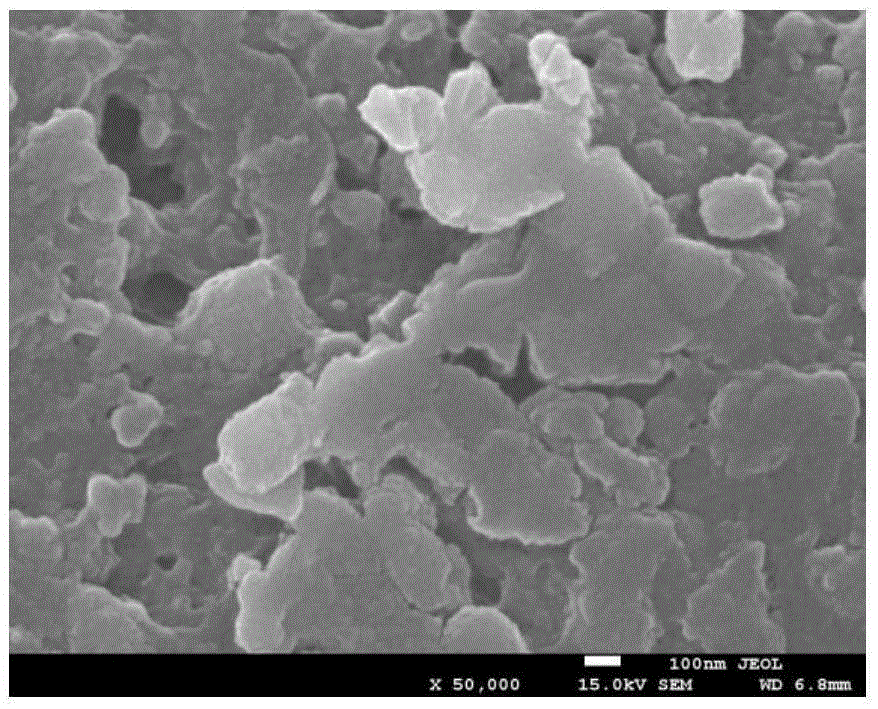

[0083] Thus, the negative electrode material CA2 with a porous core-shell structure is obtained. The particle size of the negative electrode material is D50 of 11.8 μm, the porosity is 8%, the pore diameter is 80nm, the thickness of the carbon shell layer is 1.2 μm, and the weight ratio of carbon ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com