Engine tail gas afterheat exchange method

An engine and exhaust gas technology, which is applied in the direction of engine components, combustion engines, machines/engines, etc., can solve problems such as restricting development, large consumption, and heat conduction effects of exhaust gas recovery devices, so as to avoid continuity, uninterruptibility, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

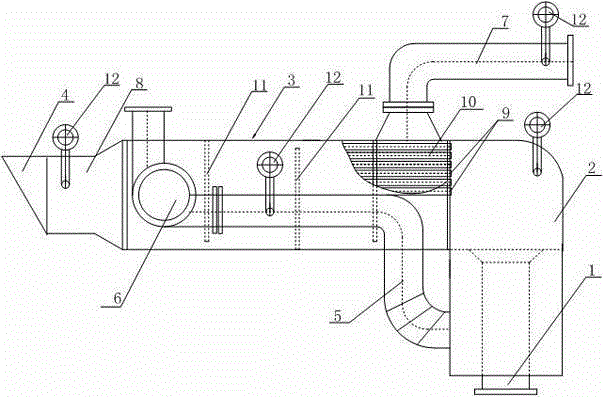

[0018] Such as figure 1 As shown, a method for exchanging waste heat of engine exhaust gas in the present invention includes a flue gas inlet 1, a smoke chamber 2, a heat exchanger 3, an anechoic chamber 8, and a smoke exhaust port 4 connected in sequence, and also includes an air inlet pipe 5, and The fan 6 installed on the air inlet pipe 5, the output end of the fan 6 enters the heat exchanger, and the heat exchanger includes an end panel 9 connected to the smoke chamber 2 and the muffler chamber 8 respectively, and forms an airtight seal with the two end panels 9. On the side wall of the chamber, a plurality of heat exchange tubes 10 connecting the smoke chamber and the muffler chamber are installed between the two end panels 9, and four baffles 11 are installed in the heat exchanger, and the baffles 11 are connected with the heat exchange The end panels 9 of the heat exchanger are parallel, and any two adjacent baffles 11 are connected to the opposite surfaces of the side ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com