High-strength aeration cone

A ventilation cone and high-strength technology, which is applied in the direction of granular/powdered fuel gasification, etc., can solve the problems of metal wire mesh without reinforcement ribs, pulverized coal pipeline and nozzle blockage, and inability to operate, so as to reduce production costs and reduce damage rate, the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below in combination with two implementations and accompanying drawings, so that those skilled in the art can implement it with reference to the description.

[0016] The first implementation

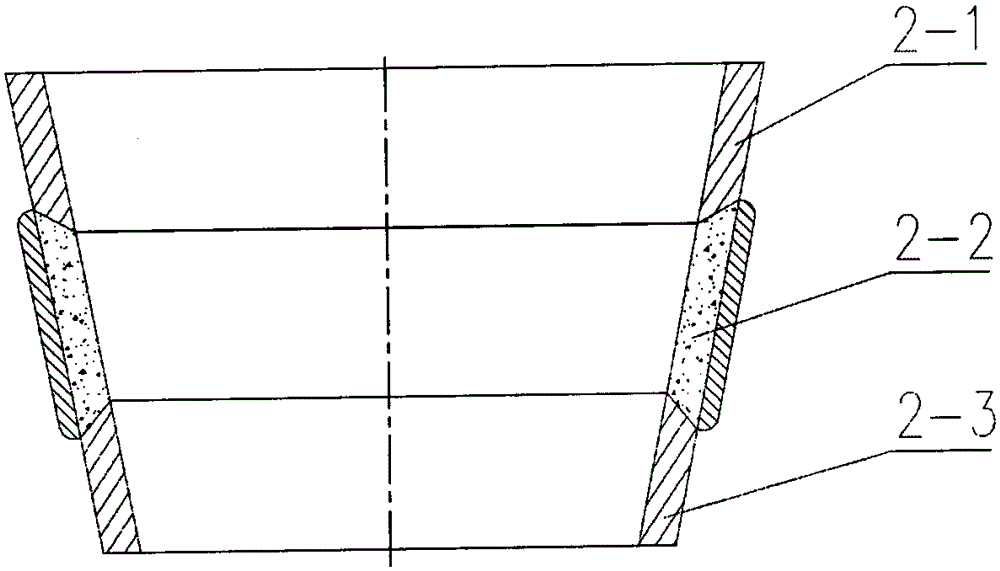

[0017] Such as figure 2 Shown is a specific embodiment of the present invention. The ventilation cone is composed of 2-1, the upper mass-dense cone section, 2-2, the sintered metal powder microporous section, and 2-3, the lower mass-dense cone section. The wall thickness of the three cone sections is The sintered metal powder microporous section 2-2 and the mass dense cone section 2-1, 2-3 are formed by cold isostatic pressing and directly sintered into a whole at high temperature, thus avoiding the sintered metal powder microporous The stress unevenness and strength weakening caused by the direct welding of the hole section 2-2 and the dense cone section 2-1, 2-3, the outer wall has a reinforcing rib integrally sintered...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com