Gradual-dissolution type hydrating mask and preparation method thereof

A gradually dissolving, wet surface technology, applied in the direction of pharmaceutical formulations, cosmetic preparations, dressing preparations, etc., can solve the problems of regurgitation of the skin, damage, easy oxidation, degradation, etc., to facilitate transportation and storage, improve dissolution sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

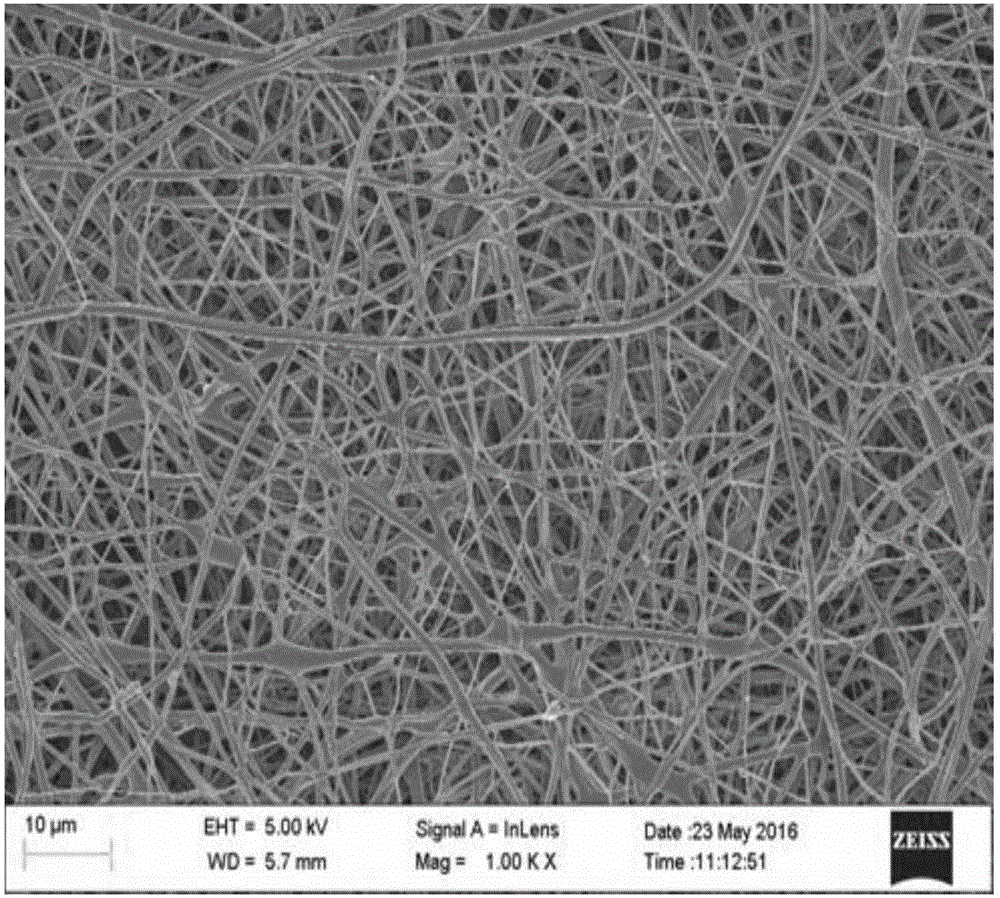

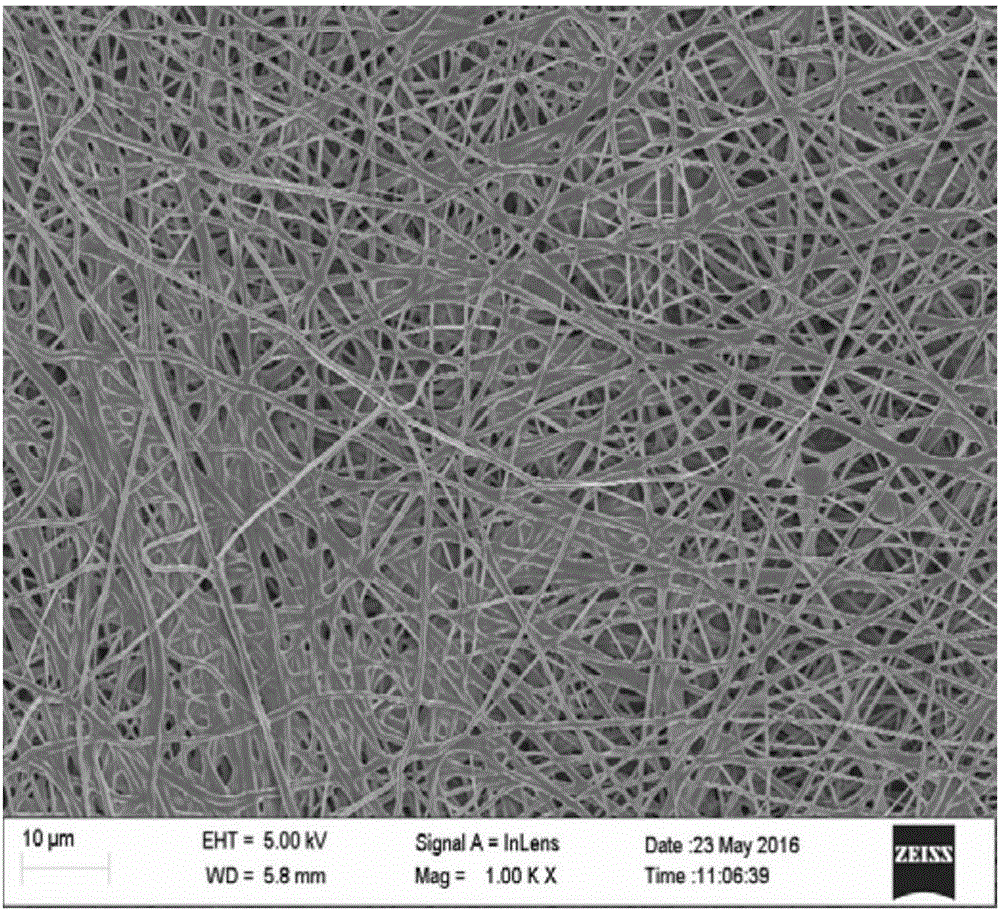

Image

Examples

Embodiment 1

[0053] (1) Add 0.15kg waxy cornstarch (food grade, Jilin Tiancheng Co., Ltd., the same below) and 0.25kg of 1-butyl-3-methylimidazole chloride (refined solution with a concentration of 98%, Lanzhou Chemical Industry Co., Ltd., Chinese Academy of Sciences) Institute of Physics, the same below) was prepared into a solution, heated to 135°C, stirred evenly for 2 hours until the starch was completely dissolved, and a uniform and transparent starch solution was obtained; then the starch solution was lowered to 75°C, and 0.0016kg of acetic anhydride (analytical grade, Guangzhou Chemical Reagent Factory, the same below), reacted for 5 hours under a nitrogen atmosphere, centrifuged and washed the reacted mixed solution with excess absolute ethanol at 3000 rpm, and vacuum-dried at 35°C to obtain starch acetate;

[0054] (2) Weigh 0.5kg of starch acetate, 1.5kg of maltose, and 8kg of deionized water in step (1) to prepare an aqueous solution, then heat to 30°C, stir evenly for 2 hours un...

Embodiment 2

[0059] (1) Prepare a solution of 0.2kg of waxy cornstarch and 0.3kg of 1-butyl-3-methylimidazole chloride, heat to 120°C, and stir evenly for 1 hour until the starch is completely dissolved to obtain a uniform and transparent starch solution; Then lower the starch solution to 70°C, add 0.001kg of acetic anhydride, react under nitrogen atmosphere for 4h, centrifuge the reacted mixed solution with excess ethanol at 3000rpm, wash, and vacuum dry at 40°C to obtain starch Acetate;

[0060] (2) Weigh 0.1kg of starch acetate, 0.5kg of maltose, and 9.4kg of deionized water in step (1) to prepare an aqueous solution, then heat to 35°C, stir evenly for 2 hours until fully dissolved, and obtain solution A; weigh 0.03 kg of disodium glycyrrhizinate, 0.06 kg of dendrobium polysaccharide extract (food grade, Jilin Tiancheng Co., Ltd.) and 9.9 kg of deionized water were prepared into aqueous solution B, heated to 25°C, and stirred evenly for 1 hour until fully dissolved;

[0061] Mix soluti...

Embodiment 3

[0064] (1) Make a solution of 0.15kg of ordinary corn starch (food grade, Jilin Tiancheng Co., Ltd.) and 0.3kg of 1-butyl-3-methylimidazole chloride, heat to 125°C, and stir evenly for 1 hour until the starch is completely dissolved , to obtain a uniform and transparent starch solution; then reduce the starch solution to 65°C, add 0.0036kg of acetic anhydride, and react for 3h under nitrogen atmosphere, centrifuge and wash the reacted mixed solution with excess ethanol, and store at 45°C Under vacuum drying, obtain starch acetate;

[0065] (2) Weigh 0.4kg of starch acetate, 1.2kg of maltodextrin, and 8.4kg of deionized water in step (1) to prepare an aqueous solution, then heat to 40°C, stir evenly for 2 hours until fully dissolved, and obtain solution A; Take 0.03kg of disodium glycyrrhizinate, 0.08kg of carboxylated chitosan extract (food grade, Jilin Tiancheng Co., Ltd.) and 9.9kg of deionized water to prepare aqueous solution B, heat to 30°C, and stir evenly for 1 hour unt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com