Pretreatment slurry for cashmere fabric digital printing and printing technology of cashmere fabric digital printing

A digital printing and fabric technology, applied in textiles and papermaking, dyeing, dry-cleaning fiber products, etc., can solve the problems of cashmere fiber damage, poor adsorption and permeability, poor fabric dyeing, etc., to reduce damage, reduce hindrance, color fastness high degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

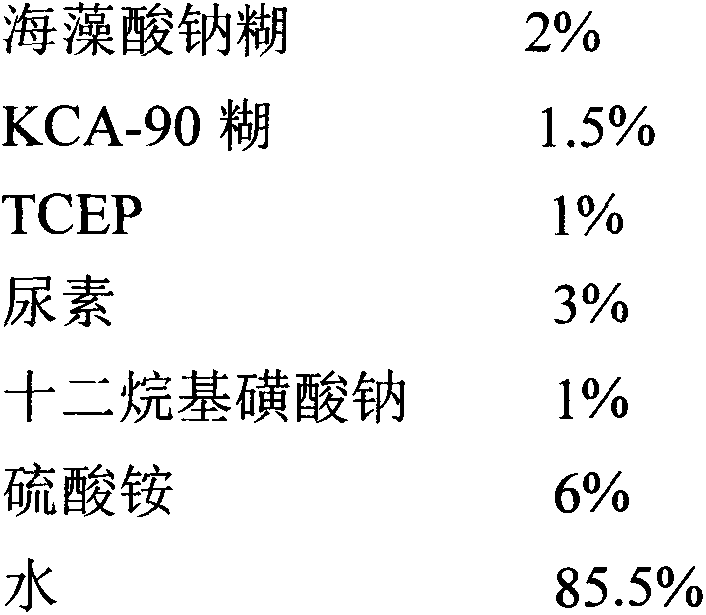

[0036] A kind of cashmere fabric pre-treatment pulp, prepared according to the following formula:

[0037]

[0038] Cashmere fabric digital printing process: sizing→drying (temperature 40°C, time 10min)→steaming (temperature 100°C, time 60min)→cold water washing (room temperature, 10min)→soaping (soaping agent A2g / L, alginic acid cracking Enzyme 1mg / L, Na 2 CO 3 0.5g / L, temperature 60°C, time 5min) → hot water wash (temperature 60°C, time 5min) → warm and cold water wash (room temperature, 5min)

[0039] According to the above-mentioned pretreatment and printing process, the k / s value of the printed fabric is 27, compared with the ratio of TCEP and sodium dodecylsulfonate not added in the pretreatment pulp, the increased value is 17, and the dry rubbing fastness is 4-5 grades, Wet rubbing fastness is grade 4, soaping and fading fastness is grade 4, cotton staining grade 4-5, wool staining grade 4-5.

Embodiment 2

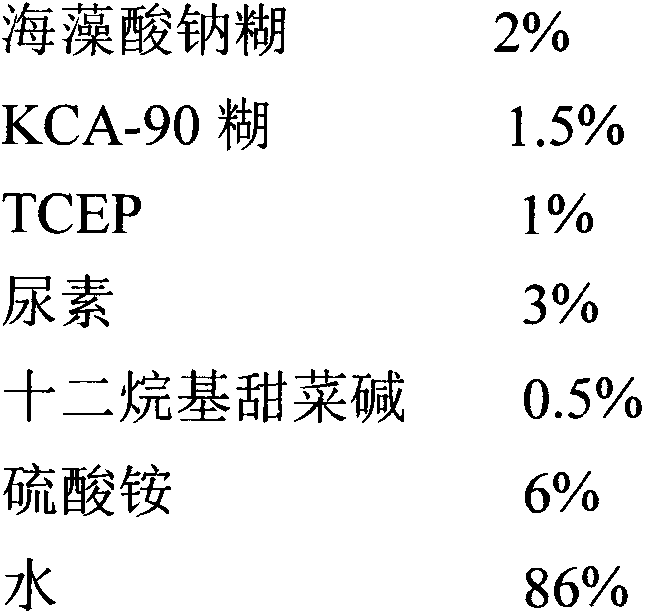

[0041] A kind of cashmere fabric pre-treatment pulp, prepared according to the following formula:

[0042]

[0043] Cashmere fabric digital printing process: sizing→drying (temperature 40°C, time 10min)→steaming (temperature 100°C, time 60min)→cold water washing (room temperature, 10min)→soaping (soaping agent A 2g / L, alginic acid Lyase 1mg / L, Na 2 CO 3 0.5g / L, temperature 60°C, time 5min) → hot water wash (temperature 60°C, time 5min) → warm and cold water wash (room temperature, 5min)

[0044] The k / s value of the printed fabric according to the above-mentioned pretreatment and printing process is 18, compared with the ratio of TCEP and lauryl betaine not added in the pretreatment pulp, the increase value is 12, and the dry rubbing fastness is 4-5 grades, wet Rubbing fastness is grade 4, soaping and fading fastness is grade 3-4, cotton staining grade 4-5, wool staining grade 4-5.

Embodiment 3

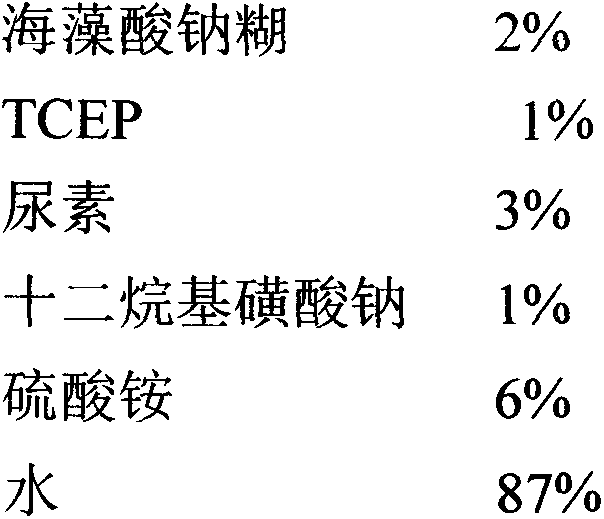

[0046] A kind of cashmere fabric pre-treatment pulp, prepared according to the following formula:

[0047]

[0048] Cashmere fabric digital printing process: sizing→drying (temperature 40°C, time 10min)→steaming (temperature 100°C, time 60min)→cold water washing (room temperature, 10min)→soaping (soaping agent A 2g / L, alginic acid Lyase 1mg / L, Na2CO3 0.5g / L, temperature 60°C, time 5min) → hot water wash (temperature 60°C, time 5min) → warm and cold water wash (room temperature, 5min)

[0049] The k / s value of the printed fabric according to the above-mentioned pretreatment and printing process is 12, compared with the ratio of TCEP and sodium dodecylsulfonate not added in the pretreatment slurry, the increased value is 5, the dry rubbing fastness is 4 grades, and the wet rubbing fastness is 4 grades. The fastness is 3-4 grades, the color fastness to soaping and fading is 3-4 grades, the cotton staining is 4-5 grades, and the wool staining is 4-5 grades.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com