Preparation method for carbon nano tube reinforced aluminum matrix composite material

A carbon nanotube and composite material technology is applied in the field of preparation of carbon nanotube reinforced aluminum matrix composite materials, which can solve the problems of weakening the strengthening effect of the reinforcement, and achieve high powder purity, low process pollution, and complete carbon tube structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

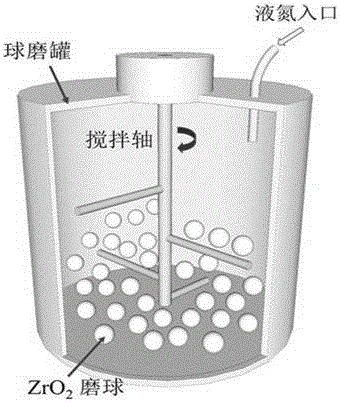

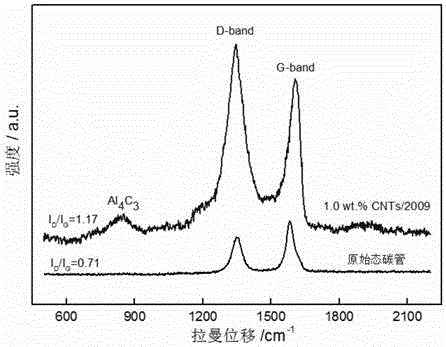

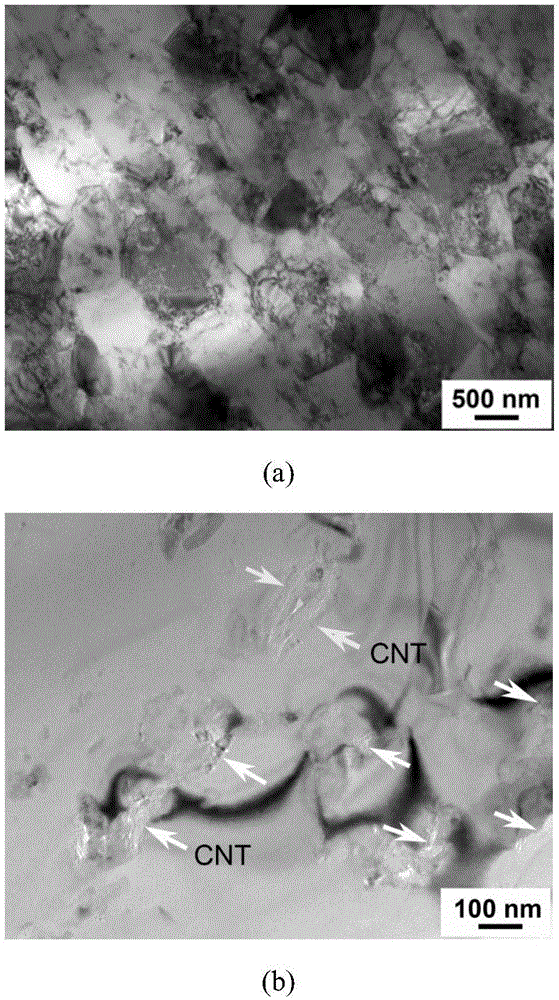

[0024] 2009 aluminum alloy powder is used, the composition is 3.0wt.% Cu, 1.5wt.% Mg, Al balance, the average particle size is 30 μm; the nominal diameter of multi-walled carbon nanotubes is 40-60 nm, and the length is 5-15 μm. Put 1kg of mixed powder of aluminum alloy powder and multi-walled carbon nanotubes and 40Kg of grinding balls into the stirring ball mill, and the material of the grinding balls is ZrO 2 , multi-walled carbon nanotubes accounted for 1.0% of the mass of the mixed powder, the diameters of the grinding balls were 3mm, 5mm, and 8mm, and the corresponding mass ratios were 2:1:1. figure 1 A schematic diagram of a stirring ball mill.

[0025] Pass liquid nitrogen into the ball mill tank, and when the balls and the mixed powder are all immersed in the liquid nitrogen, start ball milling with a rotating speed of 180r / min and a ball milling time of 2h. Pay attention to observe the amount of liquid nitrogen during the ball milling process, so that it can always s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com