A kind of preparation method of iron-ferrous sulfide complex

A ferrous sulfide and composite technology, which is applied in the field of preparation of iron-ferrous sulfide composites, can solve the problems of high cost of raw materials, dangerous synthesis process, hydrogen generation and the like, and achieves simple preparation method, low cost of raw materials, and catalytic activity. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

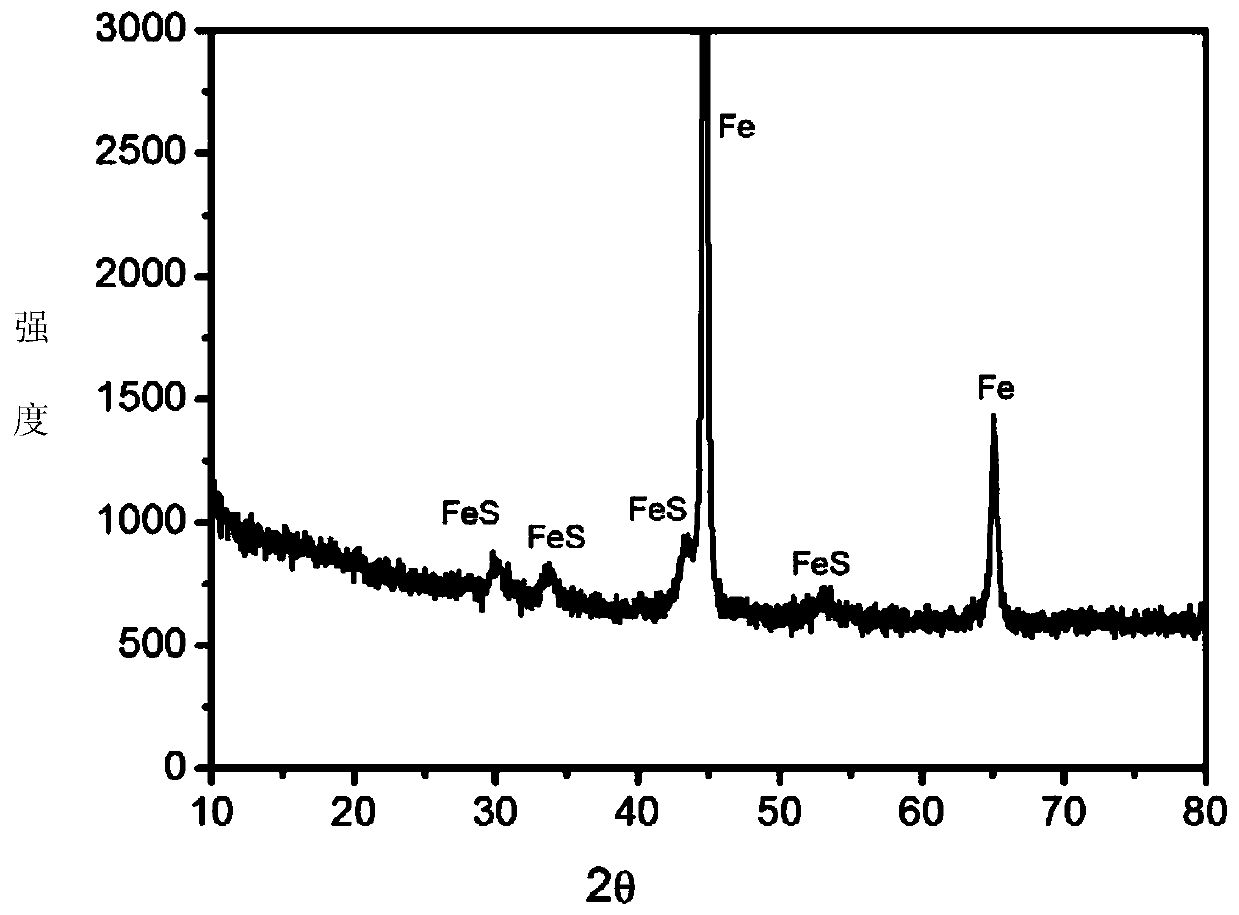

[0032] The planetary ball mill is used to prepare the iron-ferrous sulfide composite, and the steps are as follows: (1) Put 20% of the cavity volume of zirconia ball milling beads (with a diameter of 0.6mm) into the ball mill tank as a grinding medium; (2) call 0.256 g elemental sulfur powder and 2.244g zero-valent iron powder (particle size 38 microns to 74 microns) (the mass ratio of ferrosulfur is 1:8.76) are placed in a ball mill tank, and the tank is filled with nitrogen; (3) Turn on the ball mill, The grinding speed was adjusted to 500 rpm and the grinding was performed for 5 hours; (4) In a nitrogen atmosphere, the iron-ferrous sulfide composite was separated from the grinding medium with a screen to obtain the finished iron-ferrous sulfide composite.

[0033] Take trichloroethylene as an example to investigate the activity of the above materials. Add 4.25g of iron-ferrous sulfide complex to the 425mL reagent bottle, fill it up with deionized water, cover it tightly with a...

Embodiment 2

[0035] A planetary ball mill is used to prepare iron-ferrous sulfide composites, and the steps are as follows: (1) 20% of the cavity volume of zirconia ball milling beads (with a diameter of 0.6 mm) into the ball milling tank as a grinding medium; (2) weighing 0.135g elemental sulfur powder and 2.365g zero-valent iron powder (particle size 38 micrometers ~ 74 micrometers) (the mass ratio of sulfur to iron is 1:17.5) are continuously stirred and mixed uniformly in the ball mill tank, and the tank is filled with nitrogen; (3) Turn on the ball mill, adjust the grinding speed to 500 rpm, and grind for 5 hours; (4) In a nitrogen atmosphere, the prepared particles are separated from the grinding medium with a screen to obtain the iron-ferrous sulfide composite product.

[0036] Take trichloroethylene as an example to investigate the activity of the above materials. Add 4.25g of iron-ferrous sulfide complex to the 425mL reagent bottle, fill it up with deionized water, cover it tightly w...

Embodiment 3

[0038] A planetary ball mill is used to prepare iron-ferrous sulfide composites. The steps are as follows: (1) Put 20% of the cavity volume of steel ball milling beads (with a diameter of 0.8mm) into the ball mill tank as the grinding medium; (2) Weigh 0.069g elemental sulfur powder and 2.43g zero-valent iron powder (particle size 38 micron ~ 74 micron) (the mass ratio of sulfur to iron is 1:35.2) are continuously stirred and mixed in the ball mill tank, and the tank is filled with nitrogen; (3) open Using a ball mill, adjust the grinding speed to 500 rpm, and grind for 5 hours; (4) In a nitrogen atmosphere, the prepared particles are separated from the grinding medium with a screen to obtain the iron-ferrous sulfide composite product.

[0039] Take trichloroethylene as an example to investigate the activity of the above materials. Add 4.25g of iron-ferrous sulfide complex to the 425mL reagent bottle, top up with deionized water, cover tightly with a lid with Teflon septum, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com