Method for producing rigid-flex PCB lid

A technology of rigid-flex boards and manufacturing methods, which is applied in multilayer circuit manufacturing, printed circuit manufacturing, mechanical/acoustic circuit processing, etc., and can solve the problems of rigid-flex boards infiltrating liquid medicine and reducing production processes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

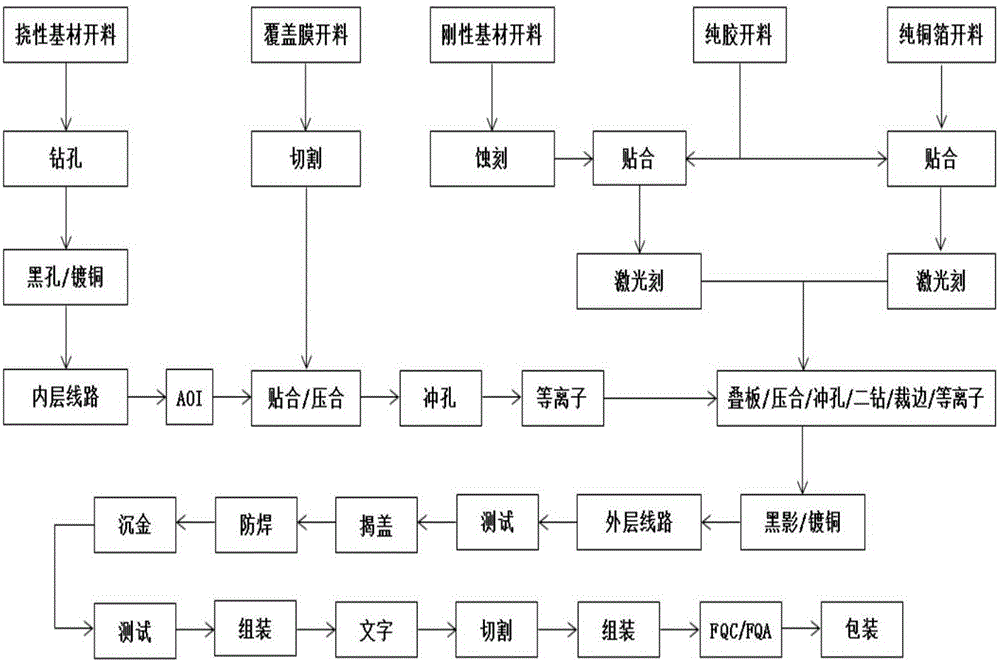

[0036] Such as figure 1 Shown, a kind of manufacturing method of rigid-flex board uncovering, it is characterized in that comprising the following steps:

[0037] Cutting: Cut the flexible base material, cover film, rigid base material, pure rubber and copper foil into sheets respectively;

[0038] The processing of flexible substrates includes the following steps:

[0039] Drilling: After cutting the flexible base material, use a drilling machine to drill through holes on the product;

[0040] Copper plating: A layer of copper is plated in the through hole of the flexible substrate to conduct the upper and lower layers of the flexible substrate;

[0041] Inner layer circuit: After copper plating on the flexible substrate, make the required graphics on the flexible substrate;

[0042] AOI: AOI inspection of flexible substrates;

[0043] Cutting: cutting the cover film into the designed shape;

[0044] Bonding: the cut and shaped cover film is bonded or pressed to the unco...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com