Diaphragm filter plate mould pressing double-face forming equipment and forming method

A membrane filter plate, double-sided molding technology, applied in the direction of household components, household appliances, other household appliances, etc., can solve the problems of easy bending deformation, uneven force on the filter plate core, liquid leakage, etc., to achieve convenient thickness, reliable sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

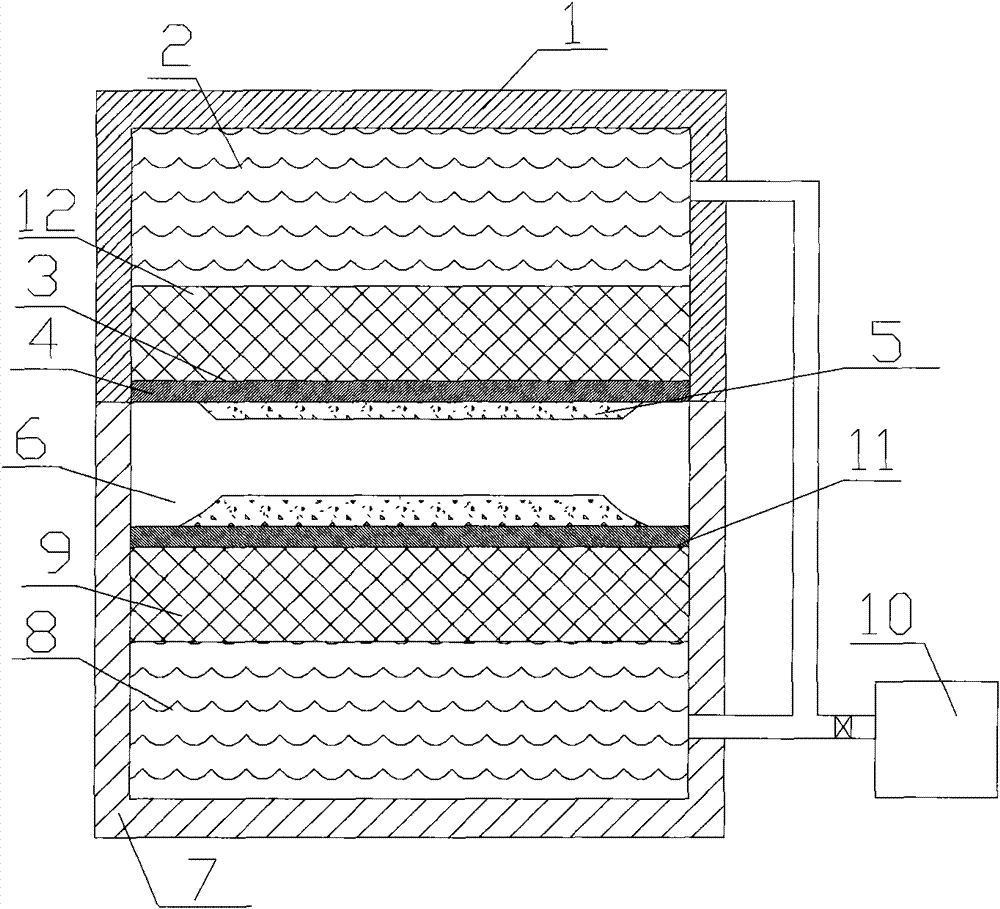

[0009] Embodiment 1: with reference to attached figure 1 . Diaphragm filter plate molding double-sided molding device, which includes an upper mold and a lower mold, the upper mold is an oil cylinder type upper mold 1 and the cavity 4 of the oil cylinder type upper mold 1 is a diaphragm forming cavity, and the forming surface 3 of the diaphragm forming cavity is The upper mold oil cylinder piston 12 faces and the upper mold oil cylinder piston 12 is located in the upper mold oil cavity 2; the lower mold is an oil cylinder type lower mold 7 and the mold cavity of the oil cylinder type lower mold 7 is a filter plate 6 and a diaphragm forming cavity, and the filter plate 6 is located in the mold cavity of the cylinder type lower mold 7, the forming surface 11 of the diaphragm forming cavity is the surface of the lower mold oil cylinder piston 9 and the lower mold oil cylinder piston 9 is located in the lower mold oil cavity 8, the upper mold oil cavity 2 and the lower mold oil ca...

Embodiment 2

[0010] Example 2: Membrane filter plate molding double-sided molding method, filter plate 6 grooves on both sides of the built-in degradable mold core 5, put the plastic mass on the surface of the cylinder type lower mold, and place the degradable mold core One side of the filter plate 6 of 5 is put into the cylinder-type lower mold and contacts with the plasticized plastic mass, and then the plasticized plastic mass is placed on the other side of the filter plate 6, and the cylinder-type upper mold 1 is commanded to move down, Press the plastic balls located on both sides of the filter plate 6 to the two sides of the filter plate 6, and form a double-sided diaphragm filter plate after cooling. The degradable mold core 5 is paper or hydrolyzed material or hydrolyzed release agent. The pressures bear between the upper die oil cylinder piston 12 and the lower die oil cylinder piston 9 are equal.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com