Membrane filter board compression molding device and molding method

A technology of molding and diaphragm filter plates, which is applied to household components, household appliances, and other household appliances. It can solve the problems of uneven force on the filter plate, bending deformation, seepage of the diaphragm and the filter plate, etc., and achieve reliable sealing. The effect of convenient thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

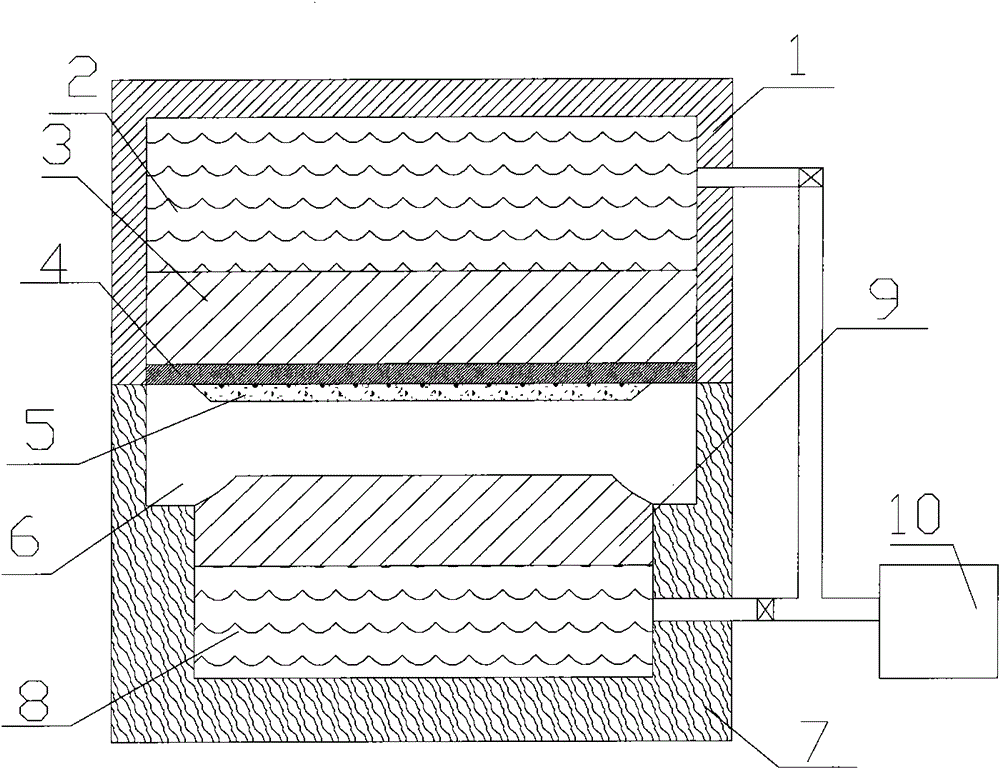

[0009] Example 1: refer to the attached figure 1 . Diaphragm filter plate molding device, which includes an upper mold and a lower mold, the upper mold is a cylinder type upper mold 1, and the mold cavity 4 of the cylinder type upper mold 1 is a diaphragm molding cavity, and the molding surface 3 of the diaphragm molding cavity is the cylinder piston surface. And the oil cylinder piston is located in the upper mold oil cavity 2; the lower mold 7 is composed of a filter plate 6 and a lower mold oil cylinder, one side of the filter plate 6 is in contact with the piston 9 in the lower mold oil cylinder, and the other side is the lower mold surface; The upper die oil cavity 2 and the piston cavity 8 are communicated with the hydraulic station 10 through an oil delivery pipe. The periphery of the filter plate 6 is in contact with the table surface of the support boss of the cylinder wall of the lower die cylinder. The face of the piston 9 matches the face of the filter plate 6 lo...

Embodiment 2

[0010] Embodiment 2: Diaphragm filter plate molding method, one side of filter plate 6 is put into the table surface of the support boss of the lower die oil cylinder wall, the lower die oil cylinder works and the surface of the piston 9 in the lower die oil cylinder is in phase with the groove surface of the filter plate. Touch, put the degradable mold core 5 on the other side of the filter plate, and then put the plastic mass on the degradable contact mold core 5. At this time, the cylinder-type upper mold 1 is instructed to move down, and the heated plastic mass is pressed. It is combined on the other side of the filter plate 6, and after cooling, a single-sided plastic membrane filter plate is formed. The degradable mold core 5 is paper or hydrolyzed material or hydrolyzed mold release agent. The pressures between the piston 13 and the piston 9 are equal.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com