Processing device for carton boards

A processing device and carton board technology, applied in paper/cardboard containers, packaging, papermaking, etc., can solve problems such as low efficiency, time-consuming and laborious, and achieve the effects of improving production efficiency, saving space, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

[0016] The present invention will be described in detail below with reference to the accompanying drawings and examples.

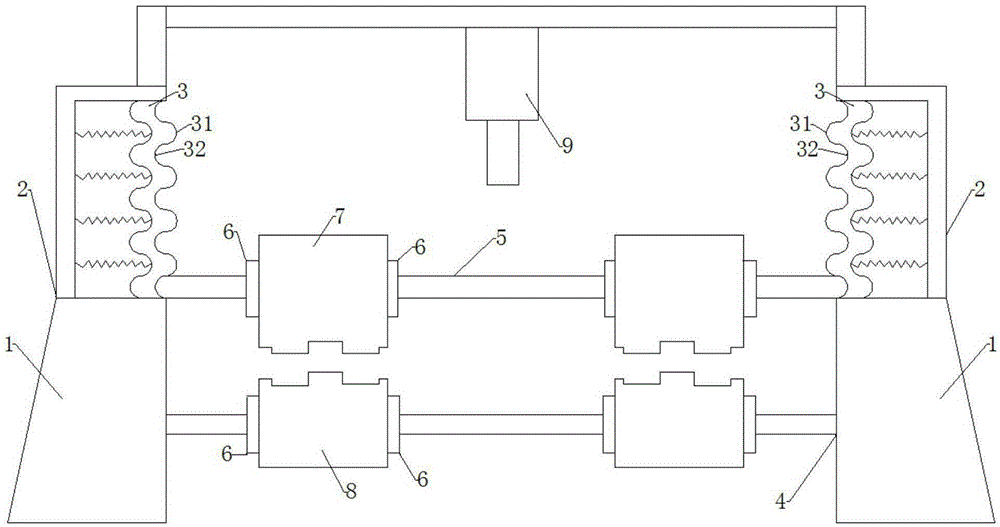

[0017] Such as figure 1 , a carton board processing device, comprising a fixed shaft 4 and a movable shaft 5, the fixed shaft 4 is fixed in the middle of two oppositely arranged bases 1, and the tops of the two bases 1 are provided with a cubic frame 2 with an inner opening, so The frame is provided with a wave-shaped adjustment plate 3, and the back of the peak 31 of the adjustment plate 3 is connected to the side of the frame facing the opening through a spring, each of the springs is arranged in parallel, and the movable shaft 5 is clamped. In the trough 32 of the wave-shaped adjustment plate 3, the fixed shaft 4 is provided with a first pressure plate 8 through a bearing 6, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com