Visual fluorescence labeling technology of silicone rubber filler network structure

A fluorescent labeling and network structure technology, applied in fluorescence/phosphorescence, analytical materials, material excitation analysis, etc., can solve the problem of increasing the complexity of the molecular chain structure of rubber materials, the limitation of research methods and technical means, and the inability to obtain the three-dimensional structure of the sample, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] In the experiment, silicone rubber, self-made silica fluorescent powder and hydroxy silicone oil were added to the internal mixer at a mass ratio of 100:40:8 for uniform mixing. The mixing temperature was 105°C, the speed was 90r / min, and the time was 15min. , and then re-milled for 10 minutes to obtain the rubber compound I; put the rubber compound I at room temperature for 7 days and then mix it with the vulcanizing agent dicumyl peroxide in an internal mixer at a mass ratio of 100:1.69. The mixed rubber II was prepared, the mixing temperature was normal temperature, the rotating speed was 60r / min, and the time was 15min. The flakes of the fluorescent functional silicon rubber composite material are obtained by pressing the tablet.

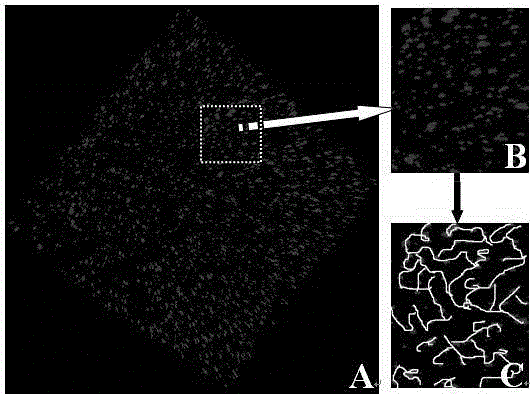

[0019] Then use frozen section technology to obtain slices with a thickness of 0.5 mm, and use laser scanning confocal microscope to scan the sample point by point, line by line, and plane by plane to obtain continuous optical slices. The...

Embodiment 2

[0021] In the experiment, silicone rubber, self-made silica fluorescent powder and hydroxy silicone oil were added to the internal mixer at a mass ratio of 100:60:8 for uniform mixing. The mixing temperature was 105°C, the speed was 90r / min, and the time was 15min. , and then re-milled for 10 minutes to obtain rubber compound I; after placing the rubber compound I at room temperature for 7 days, it was uniformly mixed with the vulcanizing agent dicumyl peroxide in an internal mixer at a mass ratio of 100:1.49, The mixed rubber II was prepared, the mixing temperature was normal temperature, the rotating speed was 60r / min, and the time was 15min. The flakes of the fluorescent functional silicon rubber composite material are obtained by pressing the tablet.

[0022] Using cryosection technology to obtain slices with a thickness of 0.5mm, using a laser scanning confocal microscope to quickly scan the sample point by point, line by line, and plane by plane to obtain continuous opti...

Embodiment 3

[0024] In the experiment, silicone rubber, self-made silica fluorescent powder and hydroxy silicone oil were added to the internal mixer at a mass ratio of 100:40:8 for uniform mixing. The mixing temperature was 105°C, the speed was 90r / min, and the time was 15min. , and then re-milled for 10 minutes to obtain the rubber compound I; put the rubber compound I at room temperature for 7 days and then mix it with the vulcanizing agent dicumyl peroxide in an internal mixer at a mass ratio of 100:1.69. The mixed rubber II was prepared, the mixing temperature was normal temperature, the rotating speed was 60r / min, and the time was 15min. The flakes of the fluorescent functional silicon rubber composite material are obtained by pressing the tablet.

[0025] Using cryosection technology to obtain slices with a thickness of 0.5mm, using a laser scanning confocal microscope to quickly scan the sample point by point, line by line, and plane by plane to obtain continuous optical slices, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com