Automobile sliding door guide rail and machining process

A technology for processing rails and sliding doors, applied in the field of automotive systems, can solve the problems of easy corrosion, affecting the appearance, and difficulty in opening and closing sliding doors, and achieves the effect of strong anti-corrosion ability, lightening labor intensity, and saving electrophoretic coatings.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

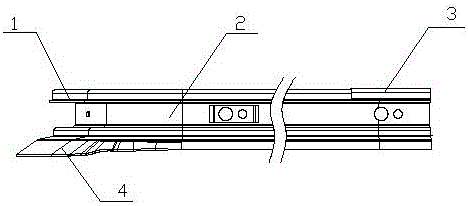

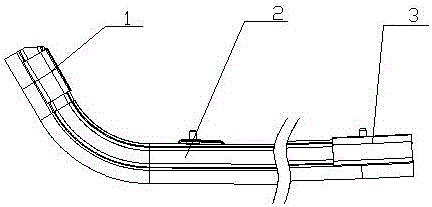

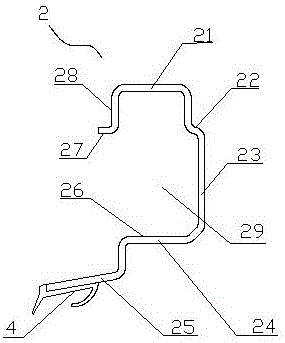

[0035] like figure 1 Shown, a kind of automobile sliding door guide rail, comprises guide rail main body 2, front support 1 and rear support 3, described front support 1 and rear support 3 are fixedly connected with the two ends of guide rail main body 2 respectively; figure 2 As shown, the guide rail main body 2 is provided with an upper chamber wall 21, a side chamber wall 23 and a load-bearing wall 24, and the described upper chamber wall 21, the side chamber wall 23 and the load-bearing wall 24 enclose a roller chamber 29, and the described The side of the upper cavity wall 21 away from the side cavity wall 23 is provided with a limiting edge 28, and the side of the load-bearing wall 24 away from the side cavity wall 23 is provided with a first rib 25; the upper cavity wall 21, the side cavity wall 23 And the surface of the first rib 25 is provided with electrophoretic paint, the lower surface of the load-bearing wall 24 is provided with electrophoretic paint, and the sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com