Method for preparing dexamethasone intermediate product through one-step microbial fermentation and transformation

A technology for dexamethasone and dexamethasone epoxy hydrolyzate, which is applied in the field of biopharmaceuticals, can solve the problems of large yield loss in the production process, long production cycle, and large equipment investment, and achieves high yield and low production cost. , The effect of easy production and operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

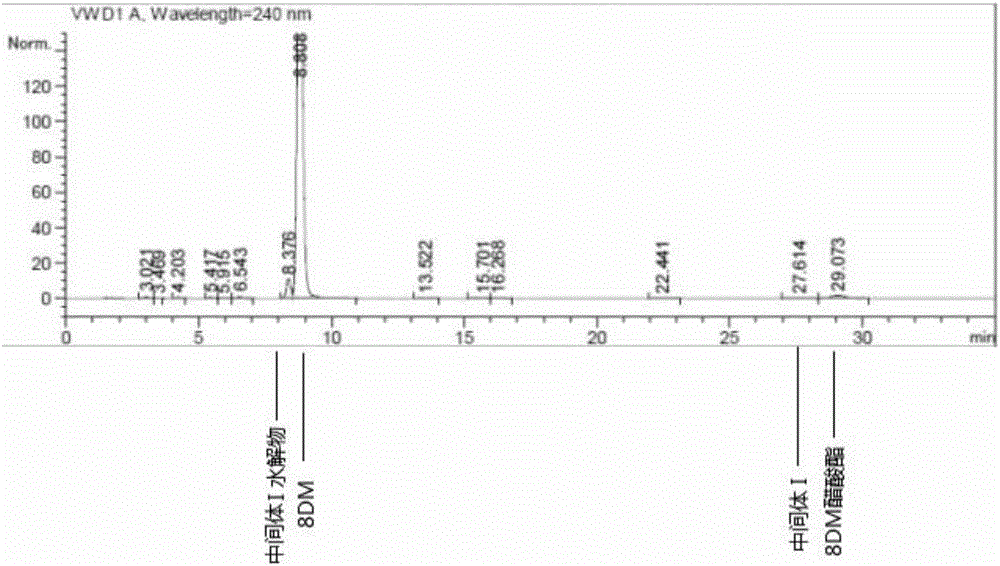

Embodiment 1

[0043] A method for preparing a dexamethasone intermediate through one-step fermentation and conversion of microorganisms, the dexamethasone intermediate refers to dexamethasone epoxy hydrolyzate (8DM), comprising the following steps:

[0044] (1) Bacteria culture

[0045] The slant culture of Arthrobacter simplex was inoculated into 200ml seed medium, and the ratio of the used seed medium was: glucose 12g / L, yeast extract powder 10g / L, KH 2 PO 4 1g / L, pH7.0~7.2, cultured on a shaker at 160rpm, 30±1°C for 30hrs;

[0046] Inoculate the slant culture of Bacillus megaterium into another bottle of 200ml seed medium, the ratio of the seed medium used is: glucose 12g / L, yeast extract powder 10g / L, KH 2 PO 4 1g / L, pH7.0~7.2, cultured on a shaker at 160rpm, 30±1°C for 30hrs;

[0047] (2) Fermentation transformation

[0048] Prepare 2000ml of fermentation medium in a 5L Erlenmeyer shaker flask, the ratio of fermentation medium is: glucose 5g / L, corn steep liquor 10g / L, peptone 1g / ...

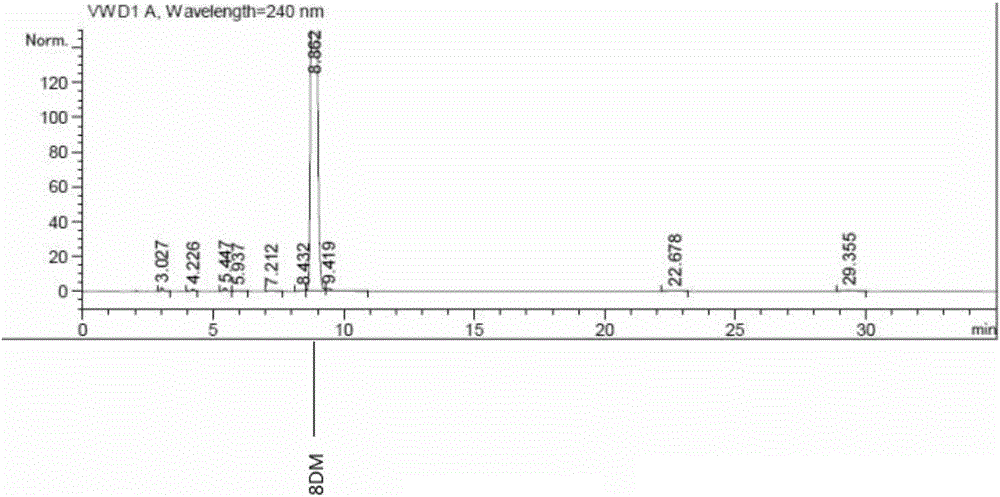

Embodiment 2

[0052] A method for preparing a dexamethasone intermediate through one-step fermentation and conversion of microorganisms, the dexamethasone intermediate refers to dexamethasone epoxy hydrolyzate (8DM), comprising the following steps:

[0053] (1) Bacteria culture

[0054] Inoculate the slant culture of Arthrobacter simplex into 400ml seed culture medium, the medium ratio used for seed culture is: glucose 12g / L, yeast extract powder 10g / L, KH 2 PO 4 1g / L, pH7.0~7.2, cultured on a shaker at 170rpm, 30±1°C for 24hrs.

[0055] Inoculate the slant culture of Bacillus megaterium into 200ml seed culture medium, the medium ratio used for seed culture is: glucose 12g / L, yeast extract powder 10g / L, KH 2 PO 4 1g / L, pH7.0~7.2, cultured on a shaker at 170rpm, 30±1°C for 24hrs.

[0056] (2) Fermentation transformation

[0057] Prepare 2000ml of fermentation medium in a 5L Erlenmeyer shaker flask, the ratio of fermentation medium is: glucose 5g / L, corn steep liquor 10g / L, peptone 1g / L,...

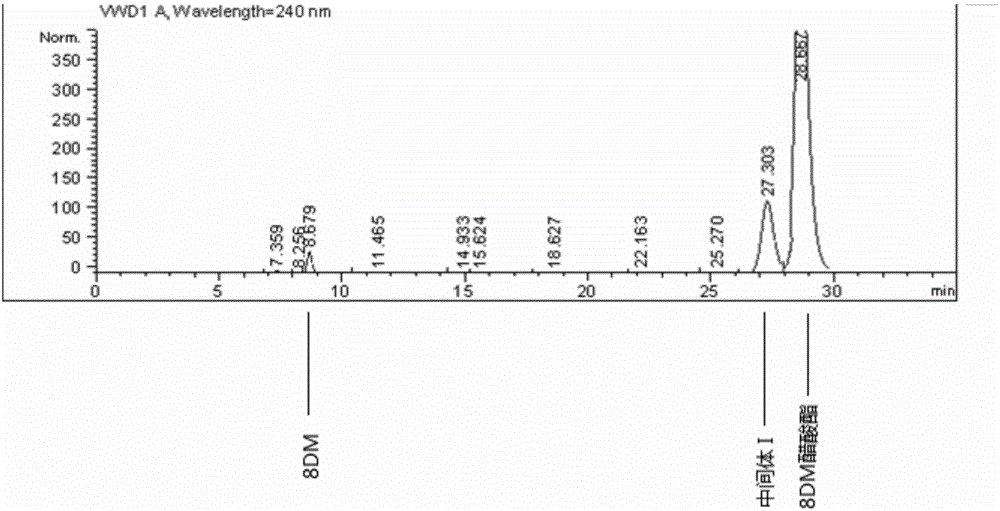

Embodiment 3

[0061] A method for preparing a dexamethasone intermediate through one-step fermentation and conversion of microorganisms, the dexamethasone intermediate refers to dexamethasone epoxy hydrolyzate (8DM), comprising the following steps:

[0062] (1) Bacteria culture

[0063] Inoculate the slant culture of Arthrobacter simplex into 400ml seed culture medium, the medium ratio used for seed culture is: glucose 12g / L, yeast extract powder 10g / L, KH 2 PO 4 1g / L, pH7.0~7.2, cultured on a shaker at 30±1°C and 170rpm for 18hr.

[0064] Inoculate the slant culture of Bacillus megaterium into 200ml seed culture medium, the medium ratio used for seed culture is: glucose 12g / L, yeast extract powder 10g / L, KH 2 PO 4 1g / L, pH7.0~7.2, cultured on a shaker at 30±1°C and 170rpm for 18hr.

[0065] (2) Fermentation transformation

[0066] Prepare 2000ml fermentation medium in a 5L Erlenmeyer shaker flask, the proportion of fermentation medium is: glucose 5g / L, corn steep liquor 10g / L, peptone...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com