A kind of method preparing ampicillin by penicillin potassium

A technology of penicillin potassium and ampicillin is applied in the field of preparing ampicillin, and ampicillin is prepared from penicillin potassium, which can solve the problems of difficulty in application, influence on the quality of ampicillin products, low concentration, etc., so as to avoid degradation and overcome the inhibition of enzyme activity. Effect, high concentration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

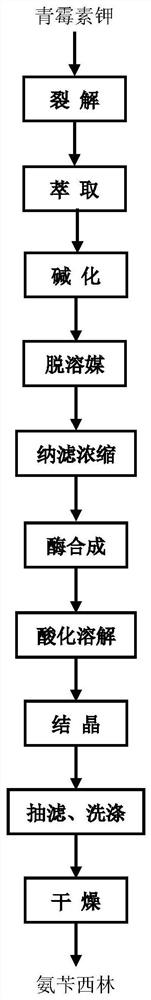

Image

Examples

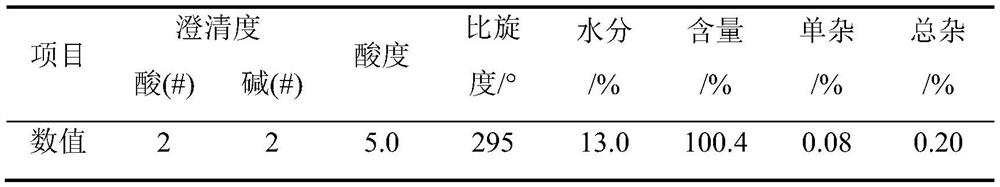

Embodiment 1

[0035] Embodiment 1 The method for preparing ampicillin by penicillin potassium according to the present invention

[0036] (1) Penicillin Potassium Cleavage

[0037] Weigh 10kg of penicillin potassium, add 100L of purified water, stir and dissolve, so that the penicillin potassium is completely dissolved, the mass concentration is 10%, then add 11.72kg of penicillin G acylase, the enzyme activity is 150u / g; Add 3.0 mol / L ammonia water to the solution, control the pH of the feed solution to 8.0, control the reaction temperature to 30°C, react for 48 minutes, stop the reaction, separate the feed solution from penicillin G acylase to obtain 125 L of penicillin potassium lysate, and take samples for determination The concentration of 6-APA was 45.82g / L, the concentration of phenylacetic acid was 28.73g / L, and the cleavage yield was 98.73%;

[0038] (2) Extraction

[0039] Lower the temperature of the penicillin potassium lysate obtained in step (1). When the temperature drops t...

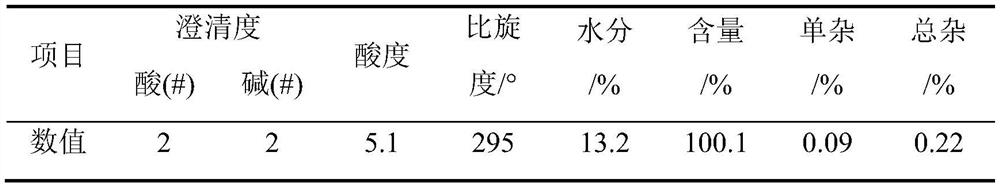

Embodiment 2

[0056] Embodiment 2 The method for preparing ampicillin by penicillin potassium according to the present invention

[0057] (1) Penicillin Potassium Cleavage

[0058] Weigh 10kg of penicillin potassium, add 125L of purified water, stir and dissolve, so that the penicillin potassium is completely dissolved, the mass concentration is 8%, then add 11.72kg of penicillin G acylase, the enzyme activity is 150u / g; Add 3.0 mol / L ammonia water to the solution, control the pH of the feed solution to 8.2, control the reaction temperature to 28°C, react for 48 minutes, stop the reaction, separate the feed solution from penicillin G acylase to obtain 160 L of penicillin potassium lysate, and take samples for determination The concentration of 6-APA was 35.81g / L, the concentration of phenylacetic acid was 22.58g / L, and the cleavage yield was 98.68%;

[0059] (2) Extraction

[0060] The penicillin potassium lysate obtained in step (1) is cooled. When the temperature drops to 2° C., add 80 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com