Metakaolin cable insulation packing and preparation method thereof

A kind of metakaolin, cable insulation technology, applied in the field of cable filler, to achieve the effect of good mechanical strength and electrical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

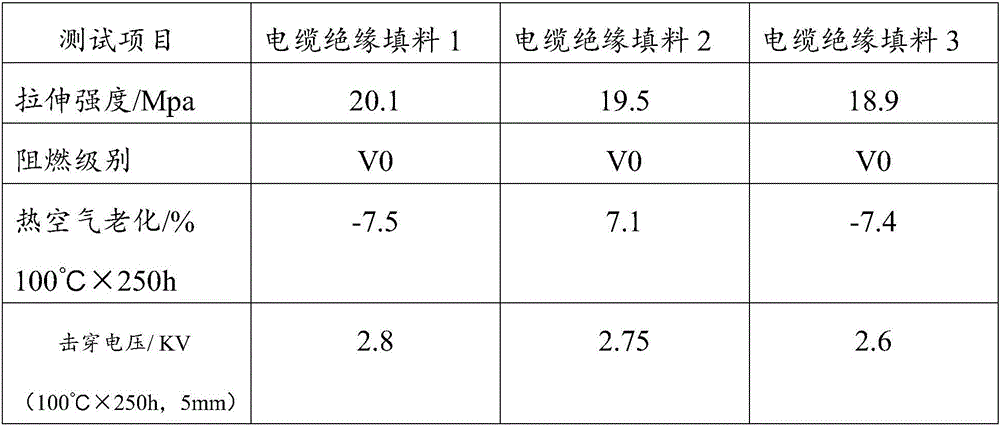

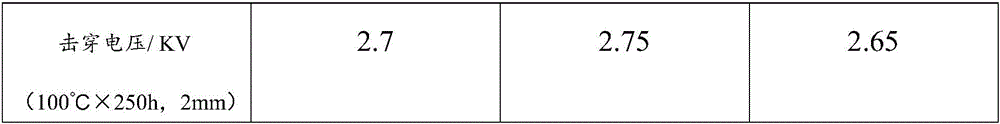

Examples

Embodiment 1

[0028] 1) the solid content is that the pH value of 57% kaolin raw ore pulp is adjusted to 6.0 and adds sodium hexametaphosphate and sodium polyacrylate dispersant, the weight of kaolin in the described sodium hexametaphosphate and sodium polyacrylate and the kaolin raw ore pulp The percentage is divided into 5‰ and 2‰, and the slurry is stirred. After stirring the pulp, grind the pulp in an ultra-fine grinder, peel off the flakes, and further press filter and dehydrate to a solid content of 65% to obtain a kaolin filter cake. Wherein, the content of kaolin particles with a particle size of less than two microns in the kaolin raw ore slurry accounts for 95 wt% of the kaolin particles in the kaolin raw ore slurry.

[0029] Among them, after the pulp passes through the 75mm and 25mm cyclones, the overflow pulp of the cyclone is then centrifugally classified by the decanter classifier, and the kaolin particle size can be controlled to less than 2 microns and the content is more t...

Embodiment 2

[0035] 1) the solid content is that the pH value of 57% kaolin raw ore pulp is adjusted to 6.0 and adds sodium hexametaphosphate and sodium polyacrylate dispersant, the weight of kaolin in the described sodium hexametaphosphate and sodium polyacrylate and the kaolin raw ore pulp The percentage is divided into 5‰ and 2‰, and the slurry is stirred. After the pulp is stirred, the pulp is ground and flaked in an ultra-fine grinder, and further press-filtered and dehydrated to a solid content of 65%, to obtain a kaolin filter cake, wherein the kaolin particles in the kaolin raw ore pulp have a particle size of less than two microns The content accounts for 95wt% of the kaolin particles in the kaolin raw ore slurry.

[0036] Among them, after the pulp passes through the 75mm and 25mm cyclones, the overflow pulp of the cyclone is then centrifugally classified by the decanter classifier, and the kaolin particle size can be controlled to less than 2 microns and the content is more than...

Embodiment 3

[0042] 1) The selected kaolin slurry with a solid content of 12% after sand removal is classified by a hydrocyclone and a decanter, so that the content of the kaolin slurry below 2 microns reaches more than 85%; The content is concentrated to 25%; the concentrated pulp is press-filtered to a filter cake with a solid content of 65%.

[0043] Among them, after the pulp passes through the 75mm and 25mm cyclone, the cyclone overflows, and the pulp is then centrifugally classified by the decanter classifier, and the kaolin particle size can be controlled to less than 2 microns and the content is more than 85%.

[0044]2) The kaolin filter cake obtained in the step 1) is flashed and dried under a slight negative pressure condition of -150pa to obtain a kaolin dry powder with a moisture content below 1.5%.

[0045] 3) Calcining the dry kaolin powder obtained in step 2) with biological particles as the combustion medium at a calcination temperature of 750° C. and a calcination time of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com