Catalytic wet oxidation method of cyanogen-containing industrial wastewater

A technology for catalytic wet oxidation and industrial wastewater, applied in chemical instruments and methods, oxidized water/sewage treatment, physical/chemical process catalysts, etc. The effect of improving catalyst strength, prolonging service life and good technical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] 1) Take an appropriate amount of nano-component oxide and binder, i.e. 85wt% TiO 2 , 15wt% ZrO 2 And account for 2wt% of the whole oxide weight of methyl cellulose, ball milling and dry mixing for 4h;

[0019] 2) Transfer the aforementioned mixture into a mud mill, add 5wt% HAc aqueous solution dropwise, and stop adding the solution when the whole mixture is about to change from powder to fine particles, lumps or agglomerates, and then knead for 4 hours;

[0020] 3) The refined mud is aged below 10°C for 12 hours before forming;

[0021] 4) Select a suitable orifice plate such as Φ1.6mm to continuously extrude thin strips. When extruding, pay attention to the screw speed and the pressure in the chamber, keep the speed at about 50r / min, and the pressure at about 80MPa;

[0022] 5) The formed thin strip carrier green body is naturally dried for 8 hours, and forced to dry in an oven for 24 hours;

[0023] 6) Roast according to the following procedures:

[0024] RT (6...

Embodiment 2~13

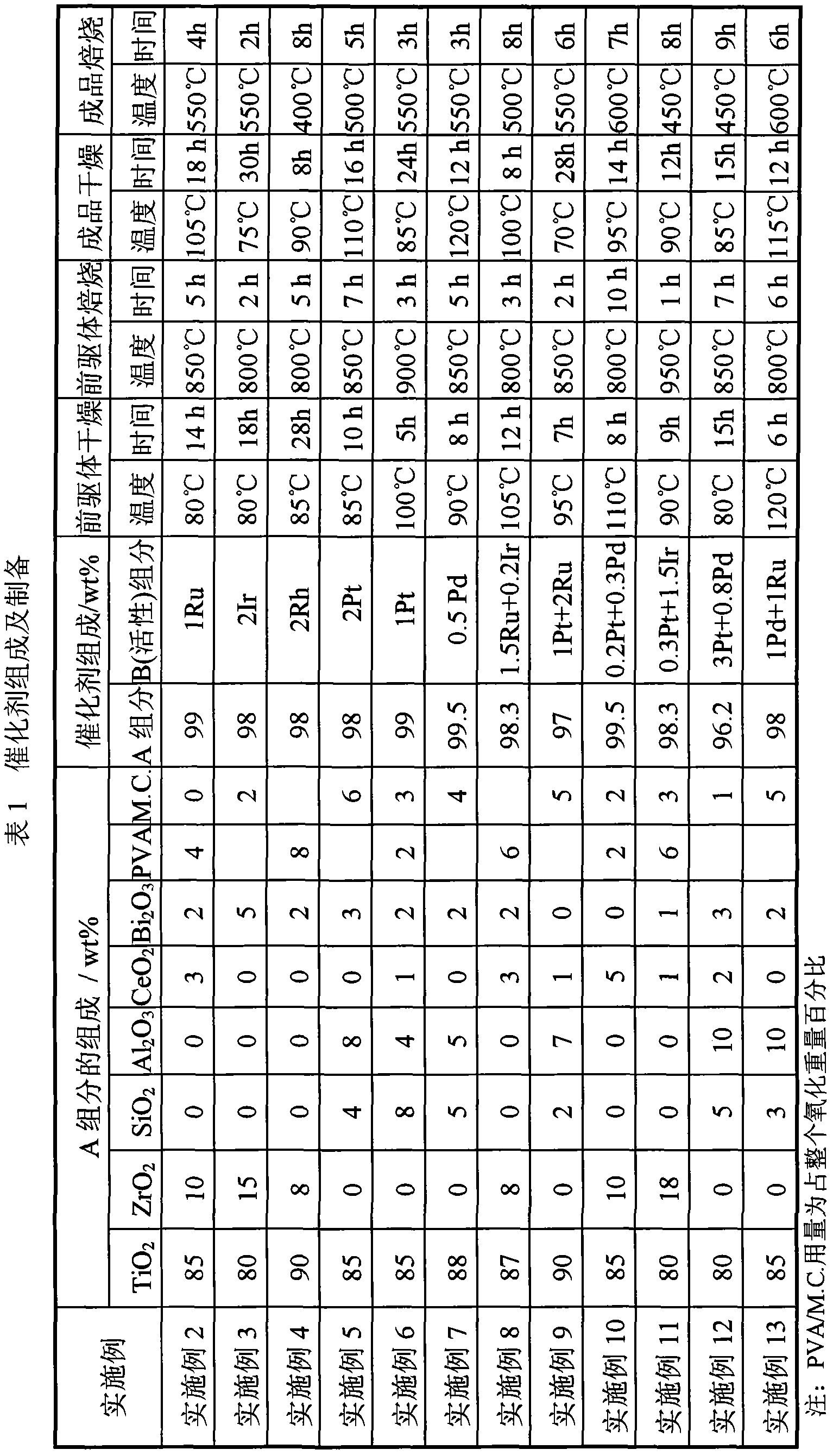

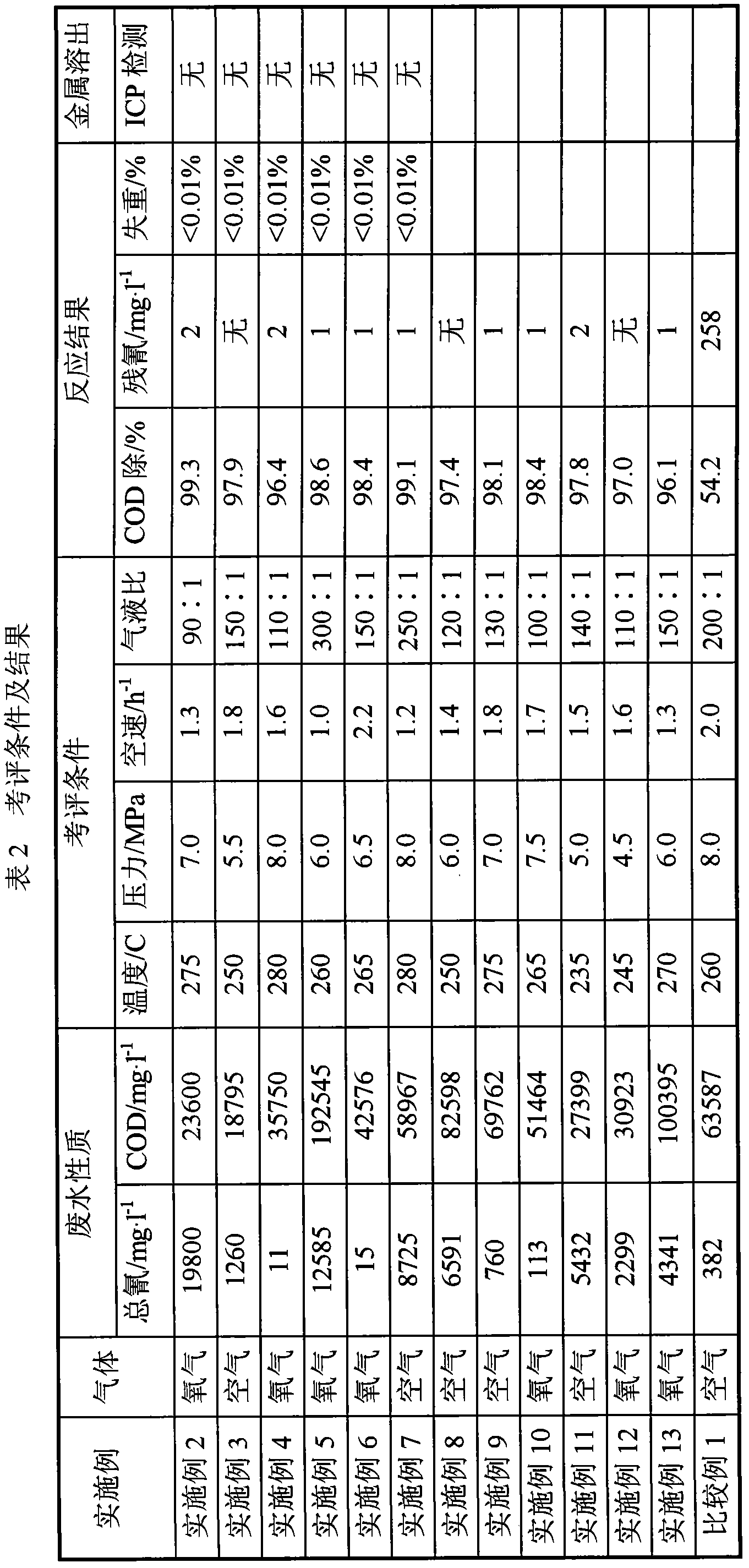

[0042] The preparation method is the same as in Example 1, only the raw material components and their proportions are changed, and the drying and roasting conditions are changed. The obtained catalyst is shown in Table 1; under different wastewater and evaluation conditions, the reaction results of the catalyst are shown in Table 2.

Embodiment 14~17

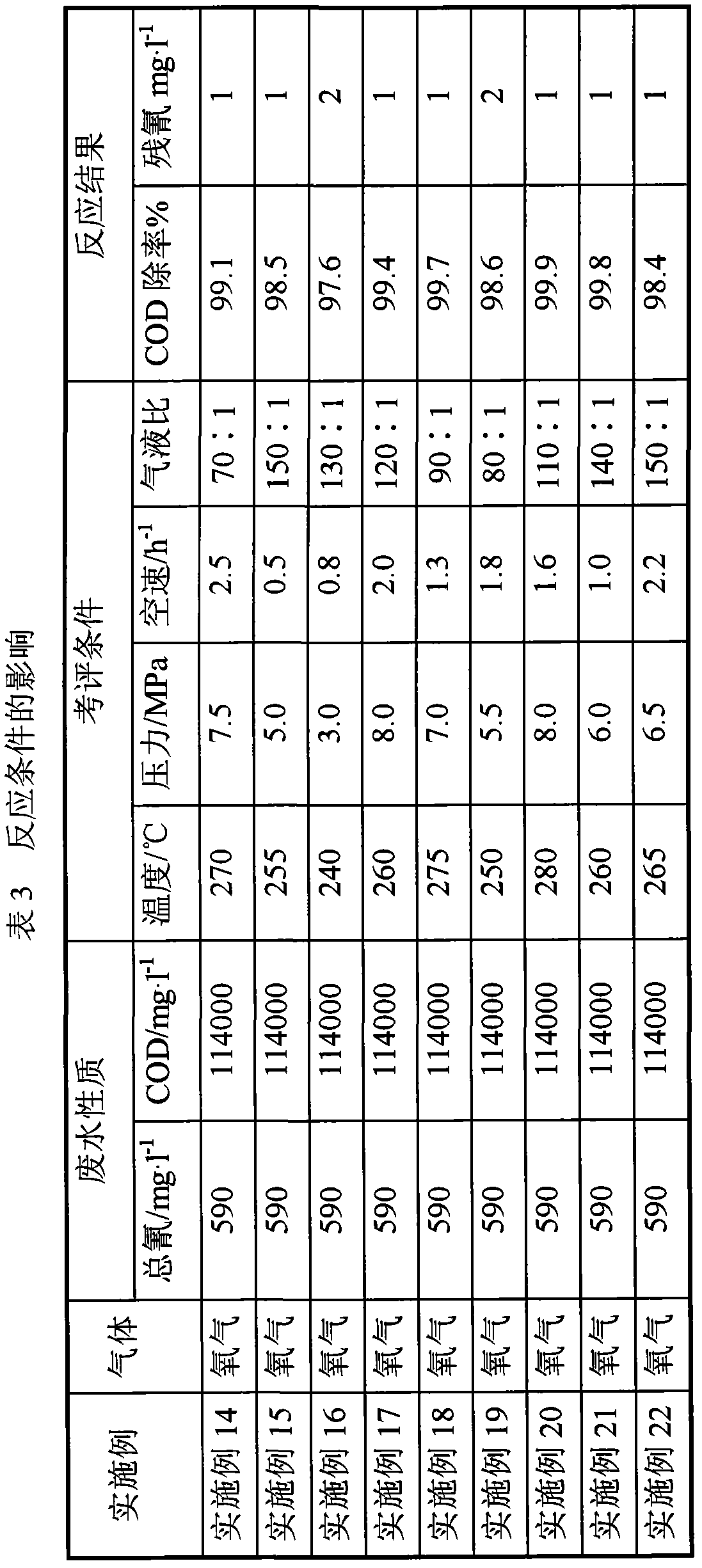

[0044] Using the catalyst prepared in Example 2, the reaction conditions were changed, and the evaluation results are shown in Table 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com