A continuous preparing method and apparatus for cyclohexanedimethanol

A technology for cyclohexanedimethanol and dibutyl phthalate, which is applied in the field of continuous preparation of cyclohexanedimethanol, can solve the problems of complicated separation and purification equipment, low solubility of reaction raw materials, etc., so as to reduce energy consumption and simplify equipment. , the effect of reducing by-products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0069] Raw material preparation:

[0070] Put the metered butanol from the solvent tank into the esterification reaction kettle 2 through the solvent storage tank 1, then put the metered phthalic acid into the esterification reaction kettle, replace the esterification reaction system with nitrogen, and gradually heat up under stirring , as the temperature rises, the pressure of the esterification reaction system gradually reaches 1.0-1.2MPa, butanol and phthalic acid undergo esterification reaction to generate dibutyl phthalate and water, and the by-product water and excess butanol in the reaction system The water-oil phase is separated in the water separator of the esterification system, the lower water phase is slowly discharged, and the total amount of water generated is measured, and the upper oil phase solvent butanol flows into the esterification reactor again. When the discharged water phase reaches the theoretical production amount At that time, it indicates that the e...

Embodiment 2

[0075] Preparation of dibutyl phthalate and dibutyl isophthalate:

[0076] The reaction process and process conditions were the same as in Example 1, and a dibutyl phthalate / butanol solution with a concentration of 22% and a dibutyl isophthalate / butanol solution with a concentration of 20% were obtained respectively.

Embodiment 3

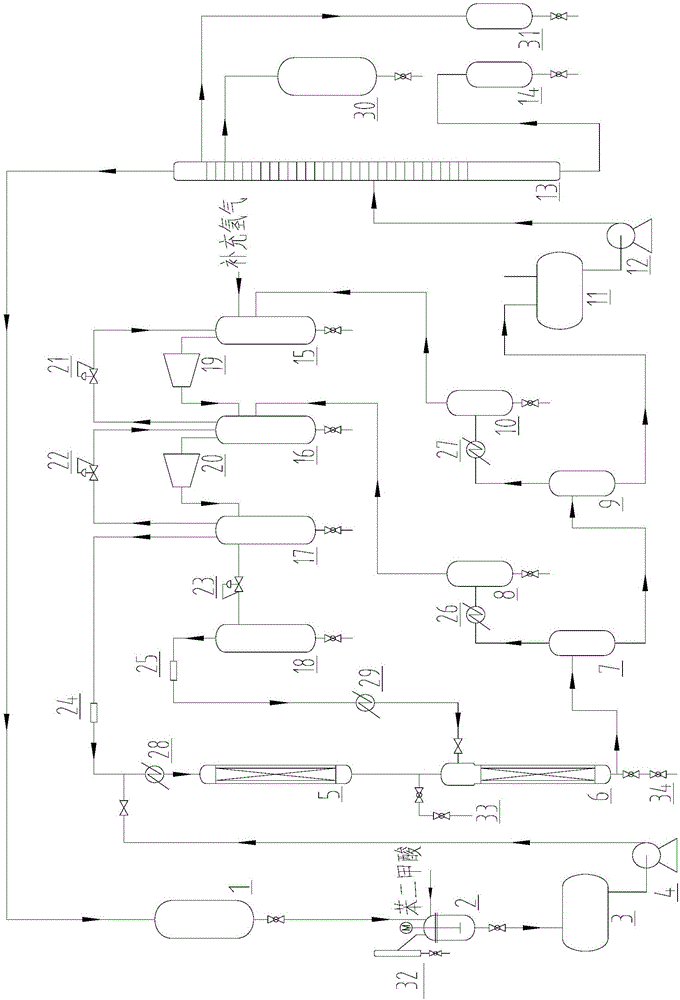

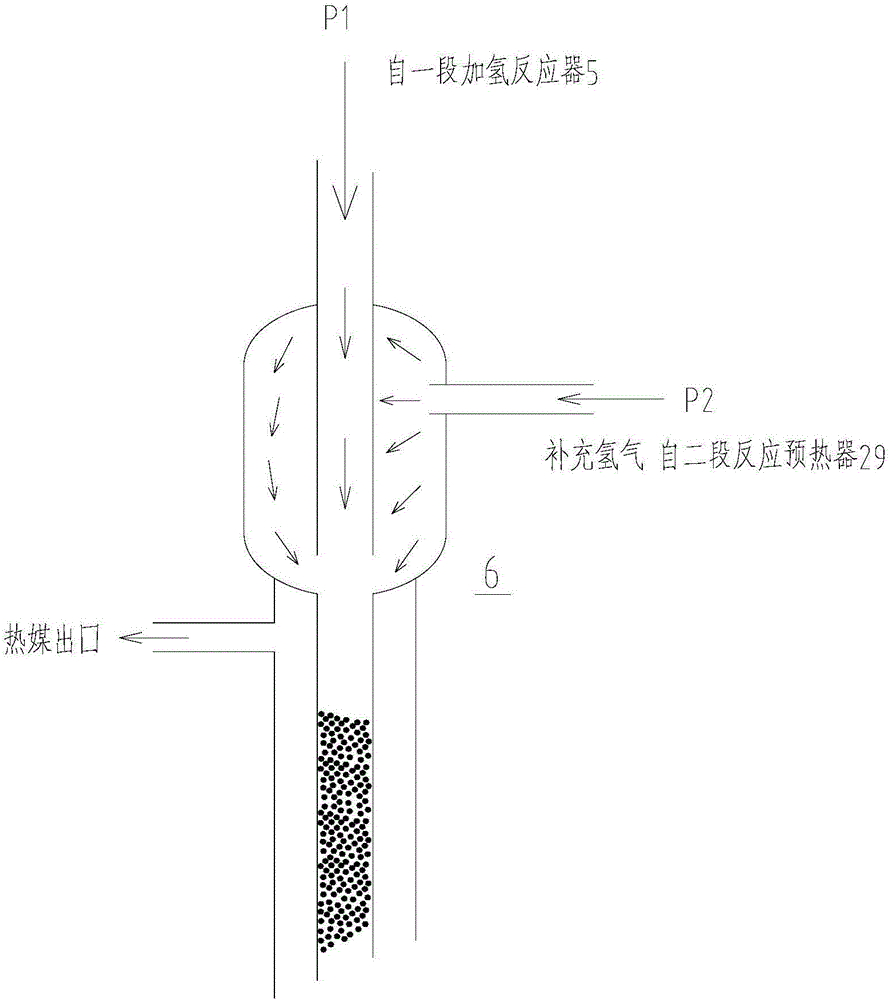

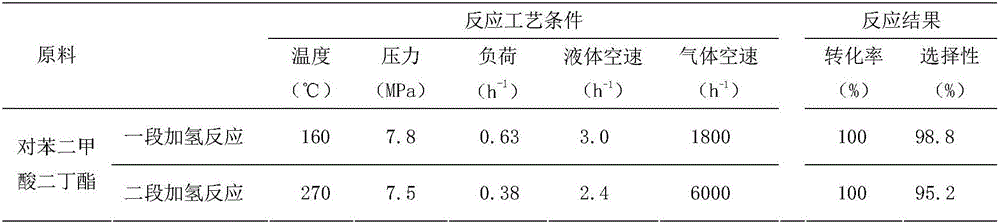

[0078] Hydrogenation reaction of dibutyl terephthalate:

[0079] After the dibutyl terephthalate / butanol solution in the raw material storage tank 3 is pressurized and metered by the high-pressure metering pump 4, it is mixed with the hydrogen from the first-stage hydrogen mass flow control valve 24 and preheated by the first-stage reaction preheater 28 Enter the first-stage reactor 5, carry out the hydrogenation reaction of the benzene ring in the catalyst bed at a certain temperature, pressure, and hydrogen-to-oil ratio, and the generated dibutyl cyclohexanedicarboxylate / butanol solution exits the first-stage reactor 5. The hydrogen from the second-stage hydrogen mass flow control valve 25 is preheated by the second-stage reaction preheater 29, mixed with the first-stage hydrogenation mixture, and enters the second-stage reactor 6. The ester group hydrogenation reaction is carried out at an oil ratio to generate 1, 4-cyclohexanedimethanol, the mixed product of the second-sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com