Rectifying the carbon fiber composite material profile and its preparation method

A composite material and carbon fiber technology, applied in the field of fairings, can solve the problems of reduced bonding fastness, corrosion of water leakage holes, and inability to completely limit water immersion into the cloth, so as to improve the bonding fastness and prevent lightning strikes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

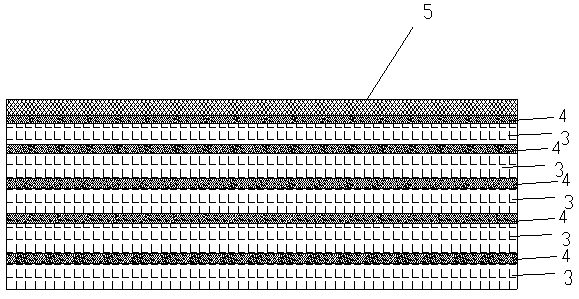

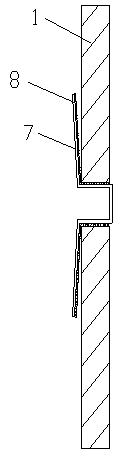

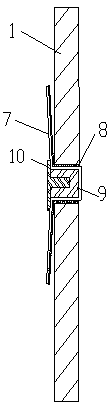

[0039] Such as Figure 1-2 As shown, this embodiment discloses a carbon fiber composite material profile for a fairing, which includes a carbon fiber composite material profile body 1 , and a water leakage hole is opened on the carbon fiber composite material profile body 1 . The carbon fiber composite profile body 1 is made of carbon fiber composite material. The carbon fiber composite material includes several layers of carbon fiber layers 3 , several layers of resin base layers 4 , and one layer of copper mesh layer 5 . The copper mesh layer 5, the resin base layer 4, and the carbon fiber layer 3 are arranged alternately from the outside to the inside. The copper mesh layer 5 is located in the outermost layer, and of course the carbon fiber layer 3 or the resin base layer 4 can be located in the innermost layer. If the carbon fiber layer 3 is located in the outermost layer, the outermost carbon fiber layer 3 is single-layer dipped in glue.

[0040] The outside of the lea...

Embodiment 2

[0055] This embodiment discloses a method for preparing the above-mentioned carbon fiber composite profile for a fairing, comprising the following steps:

[0056] (1) Glue dipping: dip five pieces of polyacrylonitrile-based activated carbon fiber cloth into the glue solution of epoxy resin glue. Wherein the mass ratio of epoxy resin and dicyandiamide curing agent in the epoxy resin glue solution is 1:1.

[0057] (2) Laying up: polyacrylonitrile-based activated carbon fiber cloth and a layer of copper mesh are laminated sequentially on the mold to ensure that the copper mesh is located on the outermost layer; the resin base layer and the carbon fiber layer are arranged under the copper mesh layer and arranged alternately in sequence ;

[0058] (3) Vacuuming: place the laminated composite material in step (2) in a vacuum environment, and vacuumize to 1.0E-3Pa.

[0059] (4) Shaping: Treat the composite material in step (3) at 200° C. and a pressure of 5 atmospheres for 2 hours....

Embodiment 3

[0063] This embodiment discloses a method for preparing the above-mentioned carbon fiber composite profile for a fairing, comprising the following steps:

[0064] (1) Glue dipping: Put three pieces of pitch-based activated carbon fiber felt and two pieces of viscose-based activated carbon fiber felt into the epoxy resin glue. The mass ratio of epoxy resin to DDS curing agent in the epoxy resin glue solution is 1:0.9.

[0065] (2) Laying: Lay three pieces of pitch-based activated carbon fiber mats, two pieces of viscose-based activated carbon fiber mats, and a layer of copper mesh on the mold in order to ensure that the copper mesh is located in the outermost layer; the resin base layer and the carbon fiber layer are set It is set under the copper mesh layer and arranged in a staggered order.

[0066] (3) Vacuuming: place the laminated composite material in step (2) in a vacuum environment, and vacuumize to 3.0E-3Pa.

[0067] (4) Shaping: process the composite material in ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com