LED street lamp device

A technology of LED street lamps and lampposts, applied in the field of lighting, can solve the problems of long installation and disassembly, reduced service life, and accidents, and achieve the effects of improving power supply security, reducing equipment investment, and reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

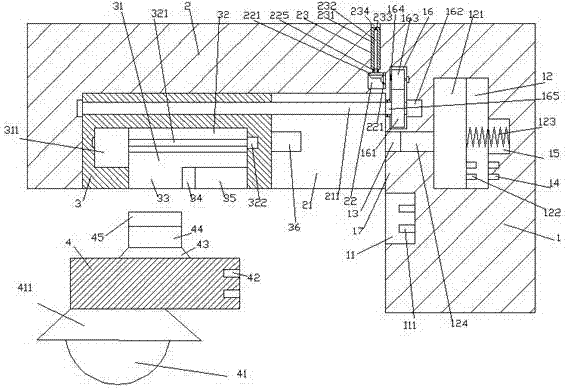

[0026] Such as Figure 1-Figure 8 As shown, an LED street light device of the present invention includes a lamp post 5, a body 1, a bracket 2 fixedly arranged at the upper left of the body 1, and a lamp holder 4, and a base 51 is fixed at the bottom of the lamp post 5. A straight rod 52 is provided on the upper left side of the lamp post 5, one end of the straight rod 52 facing away from the lamp post 5 is fixedly connected to the right end surface of the body 1, and the body 1 under the bracket 2 is provided with a plug Slot 11, a first pin 111 is provided in the slot 11, a first sliding groove 21 is provided in the bottom end surface of the right side of the bracket 2, and a locking part 3 is provided in the first sliding groove 21, The first sliding groove 21 is provided with a first threaded rod 211 that is connected to the locking portion 3 in a threaded pattern and extends to the left and right sides. In the body 1 on the right side of the bracket 2 A first sliding conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com