Composite filter material loaded with three-way denitrification and anti-sulfur catalyst in situ and preparation method thereof

A composite filter material and catalyst technology, applied in chemical instruments and methods, separation methods, filtration and separation, etc., can solve the problems of weak binding force between catalyst and filter fiber, difficult loading of denitrification and anti-sulfur catalyst, uneven catalyst loading, etc. , achieve good oxygen storage and redox performance, uniform and firm loading, and improve anti-sulfur activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

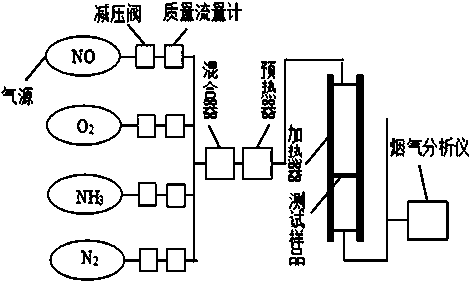

Method used

Image

Examples

Embodiment 1

[0026] 1) Weigh a piece of polyphenylene sulfide needle felt with a mass of 0.7g, put it into a beaker, then add 0.0273g of sodium lauryl sulfate, and add 50mL of deionized water, and ultrasonicate the solution for 1h ;

[0027] 2) After ultrasonic treatment, add 0.0534g of anhydrous ferric chloride and 0.1226g of cerium chloride heptahydrate to it, ultrasonic or shake until the solute is completely dissolved, then stir at room temperature for 12 hours, so that enough iron ions and cerium ions are adsorbed on the surface of PPS ;

[0028] 3) Slowly pour 50mL of 0.013mol / L potassium permanganate solution into the solution obtained in step 2), stir and react in a water bath at 80°C for 4.5h, until the purple color of the solution disappears, which indicates that the reaction is over, take out the filter material , washed repeatedly with deionized water and ethanol several times until the extruded liquid of the filter material is clear, and then dried in an oven at 110°C for 8-1...

Embodiment 2

[0031] 1) Weigh a piece of polyphenylene sulfide needle felt with a mass of 0.7g, put it into a beaker, then add 0.0273g of sodium lauryl sulfate, and add 50mL of deionized water, and ultrasonicate the solution for 1h ;

[0032] 2) After ultrasonic treatment, add 0.0801g of anhydrous ferric chloride and 0.1839g of cerium chloride heptahydrate to it, solute or shake until the solute is completely dissolved, then stir at room temperature for 12 hours, so that enough iron and cerium ions are adsorbed on the surface of PPS;

[0033] 3) Slowly pour 50mL of 0.020mol / L potassium permanganate solution into the solution obtained in step 2), stir and react in a water bath at 80°C for 4.5h, until the purple color of the solution disappears, indicating that the reaction is over, take out the filter material , washed repeatedly with deionized water and ethanol several times until the extruded liquid of the filter material is clear, and then dried in an oven at 110°C for 8-12 hours to obtai...

Embodiment 3

[0036] 1) Weigh a piece of polyphenylene sulfide needle felt with a mass of 0.7g, put it into a beaker, then add 0.0273g of sodium lauryl sulfate, and add 50mL of deionized water, and ultrasonicate the solution for 1h ;

[0037]2) After ultrasonic treatment, add 0.1068g of anhydrous ferric chloride and 0.2452g of cerium chloride heptahydrate to it, ultrasonic or shake until the solute is completely dissolved, then stir at room temperature for 12 hours, so that enough iron and cerium ions are adsorbed on the surface of PPS;

[0038] 3) Slowly pour 50mL of 0.026mol / L potassium permanganate solution into the solution obtained in step 2), stir and react in a water bath at 80°C for 4.5h, until the purple color of the solution disappears, which indicates that the reaction is over, take out the filter material , washed repeatedly with deionized water and ethanol several times until the extruded liquid of the filter material is clear, and then dried in an oven at 110°C for 8-12 hours ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com