Inner-wound-free slight soreness medical needle and machining method thereof

A technology of needles and inner holes, which is applied in the field of medical needles, can solve problems such as clogging and deburring, which cannot meet the national standard requirements, and cannot meet the design requirements, so as to achieve the effect of eliminating pain and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

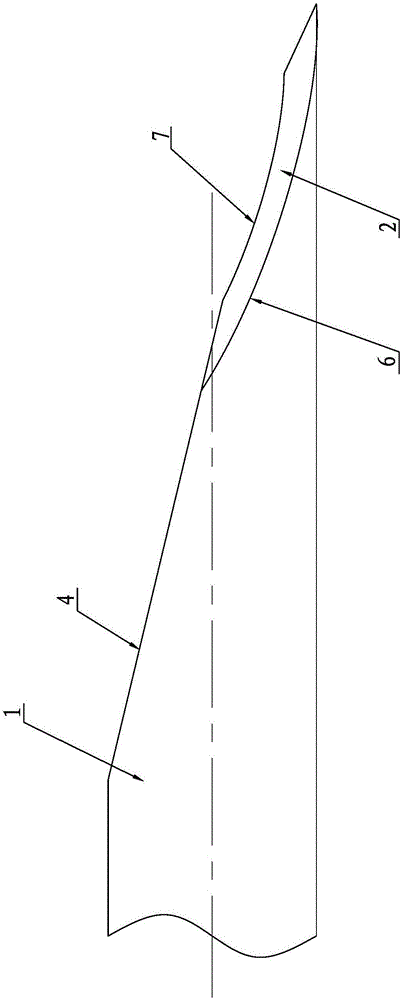

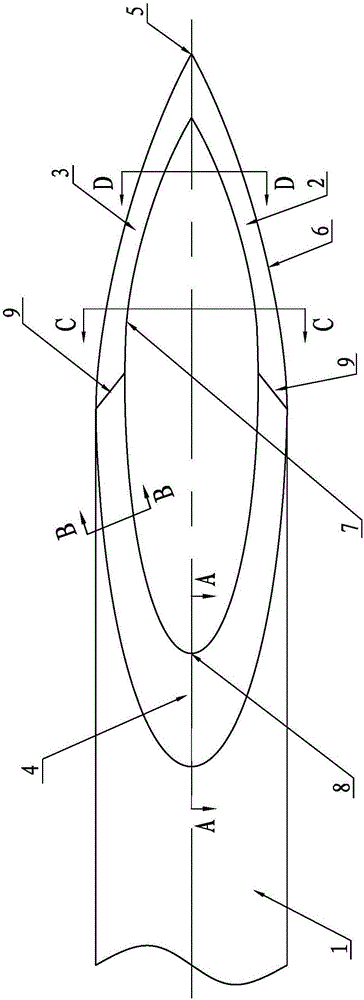

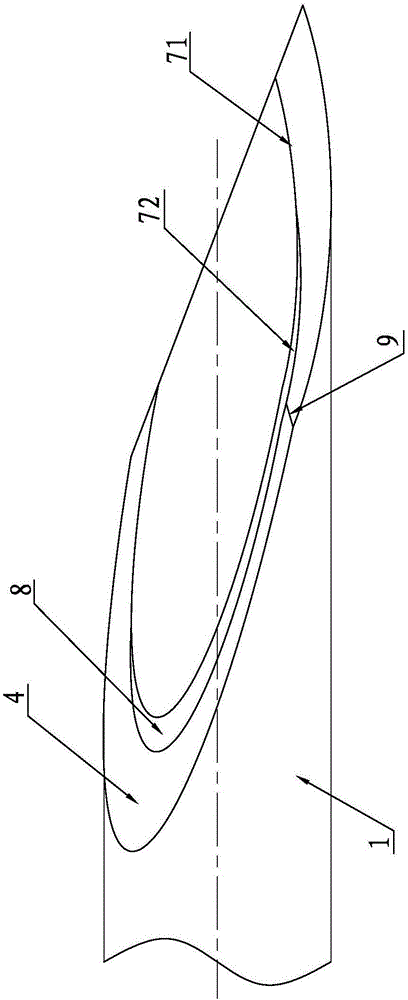

[0054] A kind of non-invasive medical needle with slight pain, such as Figure 1 to Figure 7 As shown, it includes a thin needle tube 1, and the front end of the thin needle tube 1 is provided with a left second bevel 2, a right second bevel 3 and a first bevel 4, a left second bevel 2, a right second bevel 3 and a needle The three thin tubes 1 form a needle point 5 at the front top of the needle, the outer circle of the thin needle tube 1 forms a puncture outer cutting edge 6 with the left second bevel 2 and the second right bevel 3 respectively, and the inner edge of the thin needle tube 1 The holes form a piercing inner cutting edge 7 with the left second bevel 2 and the right second bevel 3 respectively, and an internal circular arc cutting edge 8 is formed between the inner hole of the needle capillary 1 and the first bevel 4. A radial cutting edge 9 is respectively formed between the inclined plane 2, the second right inclined plane 3 and the first inclined plane 4. The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com