Multi-stage thermodynamic water supply equipment

A technology of water supply equipment and thermal power, applied in the field of multi-stage thermal water supply equipment, can solve the problems of high inlet water temperature, high condensation temperature of refrigeration system, high condensation temperature, etc., achieve high precision of water temperature control, high comfort of use, and reduce environmental pollution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

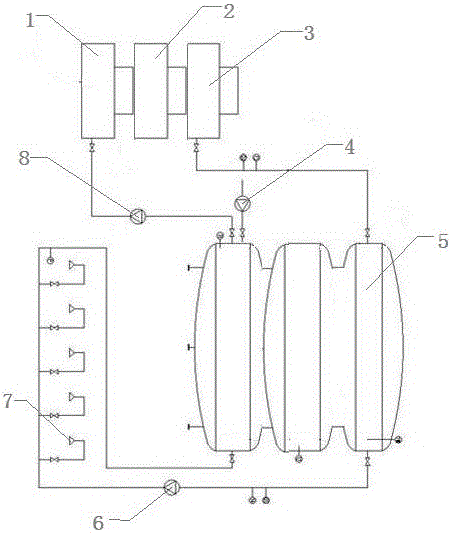

[0013] This embodiment provides a multi-stage thermal water supply equipment, characterized in that: the multi-stage thermal water supply equipment includes a primary heat pump (1), a secondary heat pump (2), a tertiary heat pump (3), and a supplementary water pump ( 4), multi-stage heat storage device (5), hot water supply pump (6), hot water use terminal (7), heating circuit pump (8);

[0014] Among them: the primary heat pump (1), the secondary heat pump (2) and the tertiary heat pump (3) form a hot water heating unit, through the supplementary water pump (4) and the heating circuit pump (8) and the multi-stage heat storage device (5) The other end of the multi-stage heat storage device (5) is connected to the hot water use terminal (7).

[0015] A control valve is provided between the hot water heating unit consisting of a primary heat pump (1), a secondary heat pump (2) and a tertiary heat pump (3) and the multi-stage heat storage device (5), and the multi-stage heat stor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com