Foamed ceramic reinforced light metal composite friction clutch disc and brake disc

A technology of foam ceramics and composite materials, applied in the direction of friction clutches, brake discs, clutches, etc., can solve problems such as lack of thickness and lack of molding methods, and achieve high-temperature softening and bonding inhibition, high-temperature resistance, and high strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

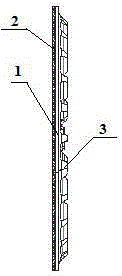

[0060] Example 1 Brake disc with single friction surface structure formed by secondary molding of different light metals

[0061] See attached Picture 1-1 and 1-2 As shown, a ceramic foam reinforced light metal composite brake disc provided in this embodiment includes a metal base 1 provided with a friction surface layer 2, the metal base 1 includes a metal disc and is arranged on The heat dissipation ribs 3 on one side of the metal plate, the friction surface layer 2 and the heat dissipation ribs 3 are respectively arranged on both sides of the metal plate, that is, the friction surface layer 2 is arranged on one side of the metal plate, the There are cooling ribs 3 on the back side of the metal disc opposite to the friction surface layer 2 . The friction surface layer 2 is a foam ceramic reinforced light metal composite material friction surface layer. The friction surface layer 2 is composed of two foam ceramic reinforced light metal composite materials arranged in a plan...

Embodiment 2

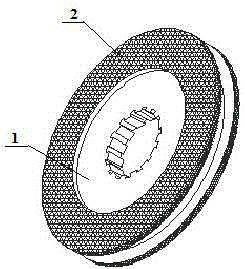

[0069] Example 2 Brake disc with double-friction surface layer whole body disc structure formed from the same metal at one time

[0070] See attached diagram 2-1 and 2-2 As shown, a ceramic foam reinforced light metal composite brake disc provided in this embodiment includes a metal base 1, and the metal base 1 is provided with two friction surface layers 2, and the metal base 1 includes a metal disc. The two friction surface layers 2 are respectively arranged on both sides of the metal disk, that is, the two friction surface layers are connected together by the metal disk between them. The friction surface layer 2 is composed of a whole piece of ceramic foam reinforced light metal composite material.

[0071] The ceramic foam of this embodiment is a silicon nitride foam ceramic skeleton, and the light metal and metal matrix filled in the foam ceramic are 7075 aluminum alloys. The specific preparation method is as follows:

[0072] Step 1: According to the design requireme...

Embodiment 3

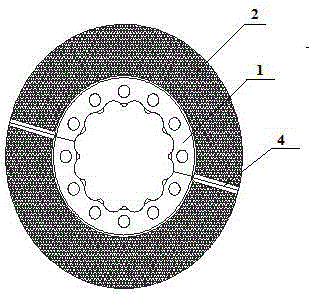

[0079] Example 3 Brake disc with double friction surface and ventilated disc structure formed from the same metal at one time

[0080] See attached Figure 3-1 and 3-2 As shown, a ceramic foam reinforced light metal composite brake disc provided in this embodiment includes a metal base 1, the metal base 1 is provided with two friction surface layers 2, and the metal base 1 includes two metal discs As well as the heat dissipation ribs 3 connecting the two metal disks, the two friction surface layers 2 are respectively arranged on the outer sides of the metal disks. The friction surface layer 2 is composed of a whole piece of ceramic foam reinforced light metal composite material.

[0081] The ceramic foam of this embodiment is a silicon carbide foam ceramic skeleton with a silicon carbide content of more than 97%, and the light metal and metal matrix filled in the foam ceramic are ZL111 aluminum alloys. This embodiment is formed by one-time low-pressure casting as a whole, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com