Preparation method and application of pH sensitive type magnetic demulsifier with surface charges and hydrophilic-hydrophobic properties controlled

A surface charge, demulsifier technology, applied in chemical dehydration/demulsification, petroleum industry, treatment of hydrocarbon oil, etc., can solve the problem of reducing the reusability of magnetic particles, and achieve the effect of simple preparation process and good dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Synthetic example 1

[0036] 1.6g FeCl 3 ·6H 2 O, 4.3g of sodium acetate and 0.48g of sodium citrate were dissolved in 60mL of ethylene glycol, stirred and dissolved, and the above solution was added to a 100mL autoclave, and reacted in a closed manner at 200°C for 12h to obtain Fe 3 o 4 Nanoparticles.

Embodiment 1

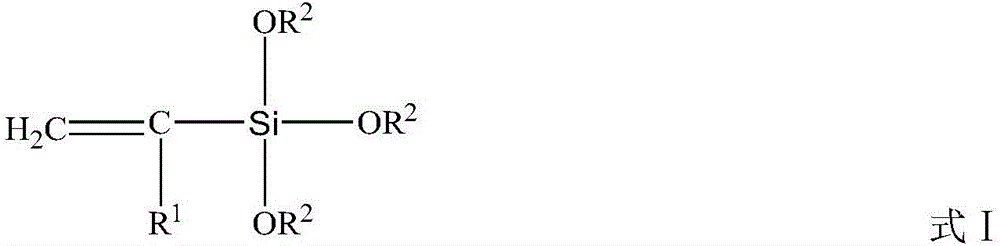

[0040] Take 0.2g Fe 3 o 4 Nanoparticles were dispersed in 160mL ethanol, 40mL water was added under the protection of nitrogen, then 0.6mL tetraethyl orthosilicate and 0.6mL 3-(methacryloyloxy)propyltrimethoxysilane (MPS) were added, and then hydrogen Adjust the pH value to 12 with sodium oxide, and react at 30°C for 6 hours to obtain Fe with polymerizable double bonds on the surface 3 o 4 @SiO 2 - MPS particles. 0.2gFe 3 o 4 @SiO 2 -MPS was dispersed in 40mL water, and 0.5g N-isopropylacrylamide, 0.5g methacrylic acid and 0.01g 2,2-azobis[2-(5-methyl-2-imidazoline) were added under nitrogen protection -2-yl)propane]dihydrochloride, reacted at 30°C for 24h to obtain a pH-sensitive magnetic demulsifier, and the grafting rate was determined to be 18.9% by thermogravimetric analysis. The above-mentioned pH-sensitive magnetic demulsifier is added to the emulsified oily sewage (diesel oil droplets, SDS concentration 10 -4 mol / L, turbidity is 1264NTU), adjust the pH value t...

Embodiment 2

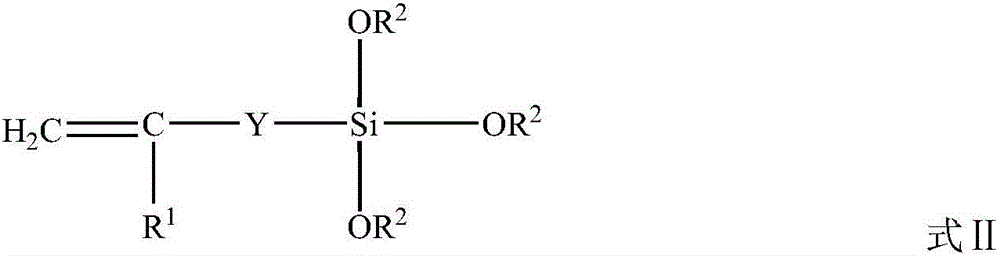

[0042] Take 0.2g Fe 3 o 4 Disperse nanoparticles in 100mL ethanol, add 100mL water under nitrogen protection, then add 1.08mL methyl orthosilicate and 0.12mL vinyltriethoxysilane (VTES), then adjust the pH value to 8 with ammonia water, 20°C After 72 hours of reaction, the Fe with polymerizable double bonds on the surface was obtained. 3 o 4 @SiO 2 -VETS particles. 0.2g Fe 3 o 4 @SiO 2 -VETS was dispersed in 40mL of water, and 0.5g of N,N-diethylacrylamide, 0.5g of methacrylic acid and 0.01g of potassium persulfate were added under the protection of nitrogen, and reacted at 80°C for 0.5h to obtain a pH-sensitive magnetic demulsifier. The grafting rate was determined to be 13.5% by thermogravimetric analysis. Add the above-mentioned pH-sensitive magnetic demulsifier to emulsified oily sewage (gasoline droplets, SDS concentration 10 -4 mol / L, turbidity is 1128NTU), adjust the pH value to below 6, find that when the amount of magnetic demulsifier reaches 120mg / L, its tur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of grafting | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com