Preparation method of water superabsorbent polyacrylic resin

The technology of polyacrylic acid resin and water-soluble acrylic acid is applied in the field of preparation of high water-absorbing acrylic resin, which can solve the problems such as the influence of working environment and operators, insufficient material feeding, poor comfort, etc., so as to improve water absorption, The effect of increasing the surface area and increasing the rate of water absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] A preparation method of a highly water-absorbent polyacrylic acid resin, which uses acrylic acid, water-soluble acrylate or water-soluble acrylic acid derivatives as polymerization monomers, and obtains a highly water-absorbent polyacrylic acid resin through aqueous solution polymerization; the specific steps are as follows:

[0037] 1) After dissolving the alkaline substance in deionized water, slowly add it to the acrylic acid monomer solution, carry out the neutralization reaction under stirring, and control the reaction temperature to ≤30°C to obtain the neutralization solution;

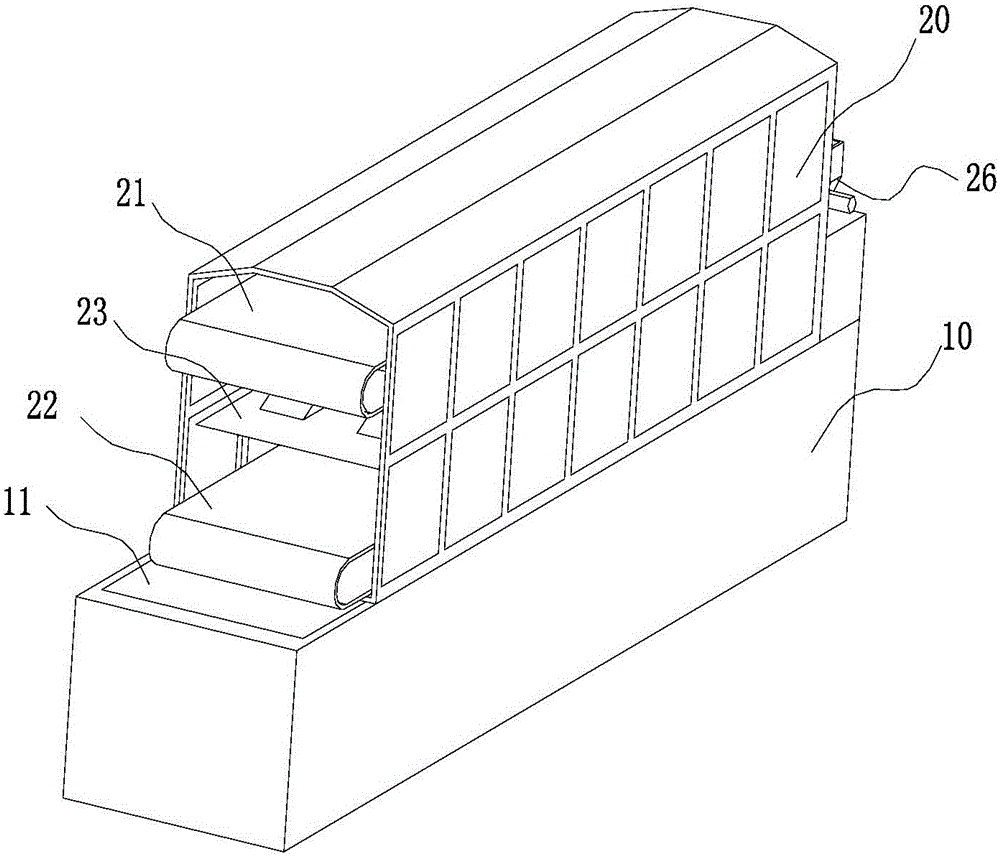

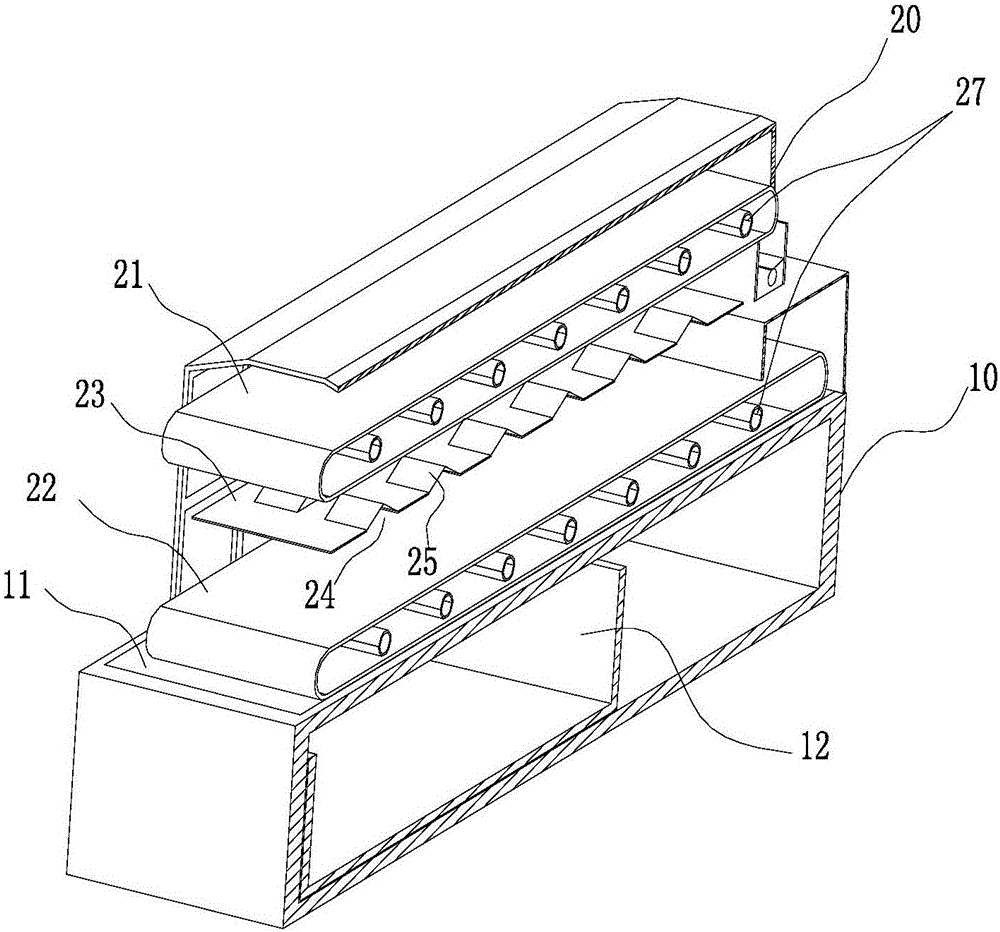

[0038] 2) Add surfactant, initiator and cross-linking agent respectively to the above-mentioned neutralization solution, stir evenly and then transfer to the belt polymerizer to start the polymerization reaction, and obtain massive elastic gel after the reaction;

[0039] 3) After cutting the massive elastic gel in step 2), transfer it to a belt dryer for drying; obtain the dried granules; ...

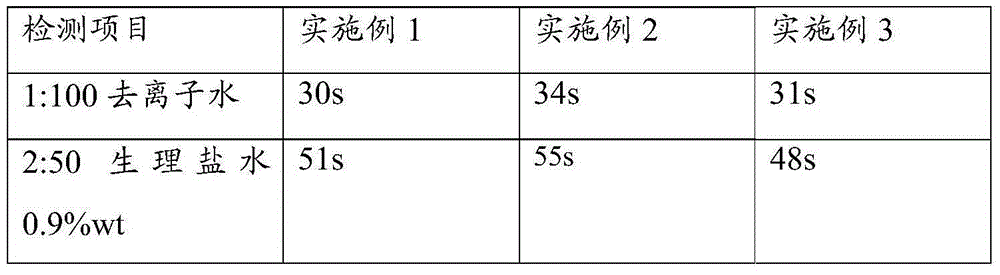

Embodiment 1

[0043] A preparation method of a highly water-absorbing polyacrylic acid resin, which uses acrylic acid as a polymerization monomer, and obtains a highly water-absorbing polyacrylic acid resin through aqueous solution polymerization under the action of a surfactant and an initiator; the specific steps are as follows:

[0044] 1) Dissolve the alkaline substance in deionized water and slowly add it to the acrylic acid monomer solution, carry out the neutralization reaction under stirring, and control the reaction temperature to 30°C to obtain the neutralization solution;

[0045] 2) Add a surfactant, an initiator and a crosslinking agent to the above-mentioned neutralizing solution, stir evenly, transfer to a belt polymerizer, and polymerize at a constant temperature at 85° C., and obtain a massive elastic gel after reaction;

[0046] 3) After granulating the massive elastic gel in step 2), transfer it to an airtight belt-type constant temperature dryer for drying at 130° C. to o...

Embodiment 2

[0051] A preparation method of a highly water-absorbent polyacrylic acid resin, which uses sodium acrylate as a polymerization monomer, and obtains a highly water-absorbent polyacrylic acid resin through aqueous solution polymerization under the action of a surfactant and an initiator; the specific steps are as follows:

[0052] 1) Dissolve the alkaline substance in deionized water and slowly add it to the acrylic acid monomer solution, carry out the neutralization reaction under stirring, and control the reaction temperature at 28°C to obtain the neutralization solution;

[0053] 2) Add surfactant, initiator and cross-linking agent respectively to the above neutralization solution, stir evenly and then transfer to belt polymerizer, perform constant temperature polymerization reaction at 90°C for 5 hours to obtain massive elastic gel ;

[0054] 3) Cut the massive elastic gel in step 2) into granules and transfer them to a closed belt type constant temperature dryer for drying ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com