High-efficiency industrial sewage treating agent

A technology of industrial sewage and treatment agent, which is applied in biological water/sewage treatment, water/sludge/sewage treatment, water treatment parameter control, etc. It can solve the complicated sewage treatment process, low sewage treatment efficiency, poor sewage treatment effect, etc. problems, to achieve the effect of good sewage treatment, high sewage treatment efficiency and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

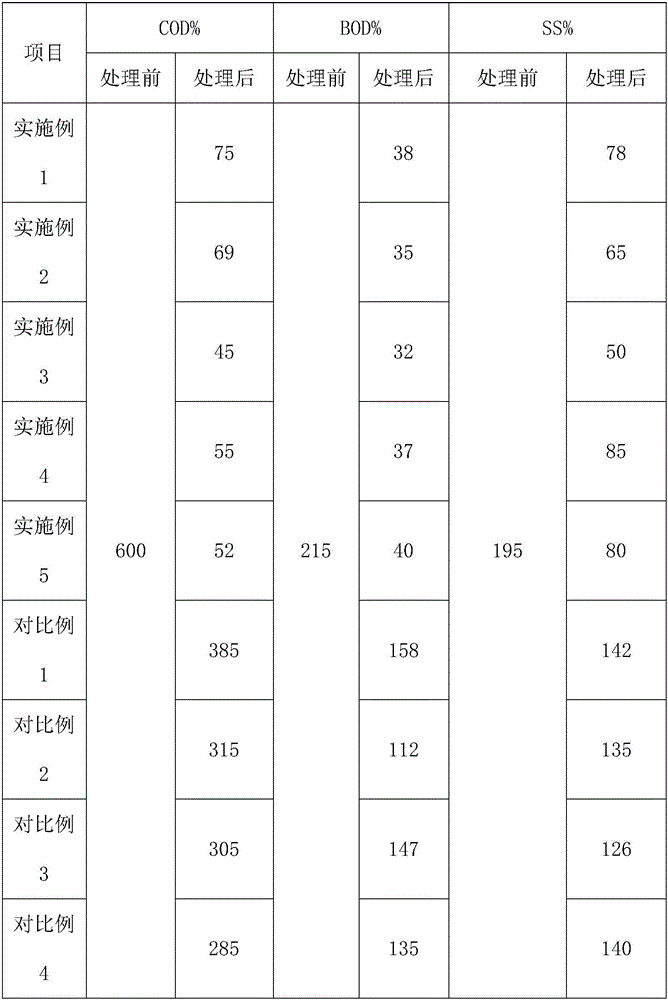

Examples

Embodiment 1

[0018] Weigh 20 parts of fly ash, 10 parts of ammonium nitrate, 5 parts of ether, 10 parts of talcum powder, 5 parts of yam, 5 parts of lactic acid bacteria, 5 parts of polysaccharide, 2 parts of sulfuric acid, and 2 parts of nano-scale alumina; wash the yam Clean and dry, then pulverize with a pulverizer, and pass through an 80-mesh sieve to obtain yam powder; mix fly ash with sulfuric acid, and use a stirrer to stir and react for 1 hour to obtain a mixture; mix yam powder with ammonium nitrate and nano-scale alumina Uniform, then add ether to obtain a mixed solution; mix the above mixture with the mixed solution, and use a microwave auxiliary instrument to stir and heat, stirring time 0.5h, reaction temperature 60°C; cool to 20°C, add talcum powder, polysaccharides and lactic acid bacteria , and stirred for 5 minutes to obtain an industrial sewage treatment agent. Wherein the mass fraction of sulfuric acid is 5%.

Embodiment 2

[0020] Weigh 30 parts of fly ash, 15 parts of ammonium nitrate, 15 parts of ether, 15 parts of talcum powder, 10 parts of yam, 10 parts of lactic acid bacteria, 10 parts of polysaccharide, 10 parts of sulfuric acid, and 5 parts of nano-scale alumina; wash the yam Clean and dry, then pulverize with a pulverizer, pass through a 100-mesh sieve to obtain yam powder; mix fly ash with sulfuric acid, and use a stirrer to stir and react for 2 hours to obtain a mixture; mix yam powder with ammonium nitrate and nano-scale alumina uniform, then add ether to obtain a mixed solution; mix the above mixture with the mixed solution, and use a microwave auxiliary instrument to stir and heat for 1 hour, and the reaction temperature is 100°C; cool to 30°C, add talcum powder, polysaccharides and lactic acid bacteria, Stir for 15 minutes to obtain the industrial sewage treatment agent. Wherein the mass fraction of sulfuric acid is 15%.

Embodiment 3

[0022] Weigh 22 parts of fly ash, 12 parts of ammonium nitrate, 10 parts of ether, 13 parts of talcum powder, 9 parts of yam, 9 parts of lactic acid bacteria, 10 parts of polysaccharide, 4 parts of sulfuric acid, and 5 parts of nano-scale alumina; wash the yam Clean and dry, then pulverize with a pulverizer, and pass through a 90-mesh sieve to obtain yam powder; mix fly ash with sulfuric acid, and use a stirrer to stir and react for 1.5h to obtain a mixture; mix yam powder with ammonium nitrate and nano-sized alumina Mix well, then add diethyl ether to obtain a mixed solution; mix the above-mentioned mixture with the mixed solution, and use a microwave auxiliary instrument to stir and heat, stirring time 0.6h, reaction temperature 80°C; cool to 25°C, add talcum powder, polysaccharide and Lactic acid bacteria, stirred for 10 minutes to obtain industrial sewage treatment agent. Wherein the mass fraction of sulfuric acid is 10%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com