Stirring apparatus for producing coatings

A technology of stirring device and coating, which is applied to mixers with rotary stirring devices, accessories of mixers, transportation and packaging, etc., can solve the problems of low stirring efficiency and long stirring time, and achieve high efficiency, large gaps, and reduced material mixing. Effects of Probability of Foreign Substances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

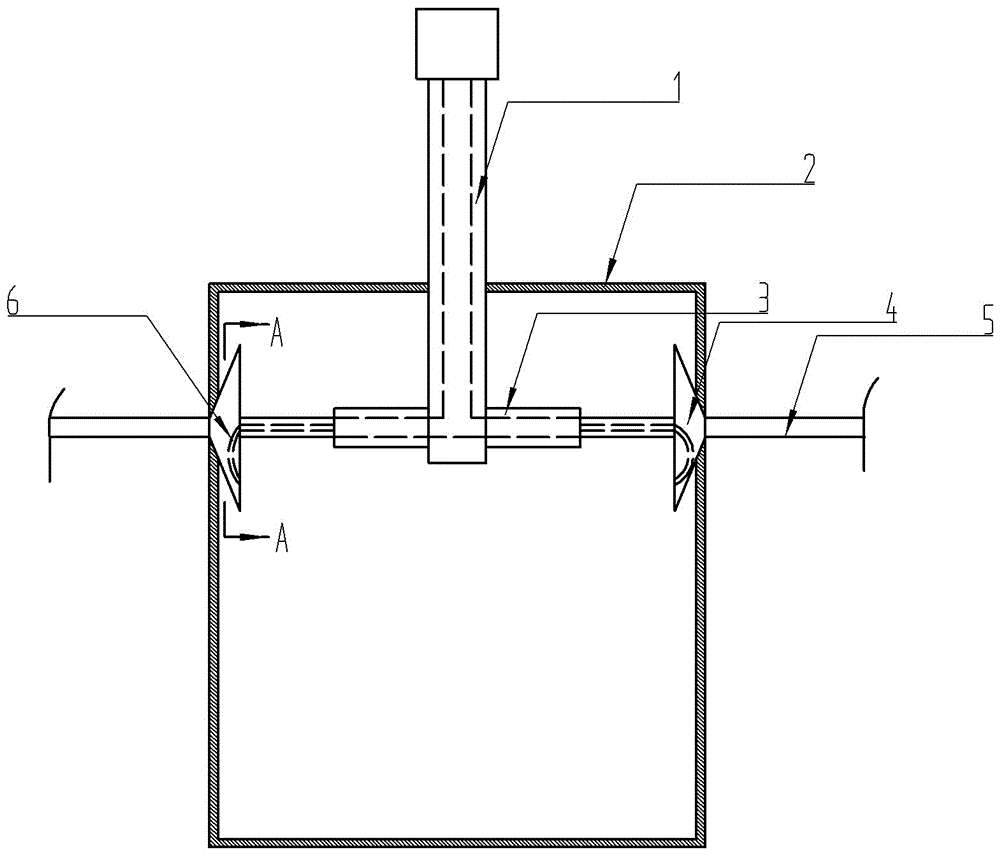

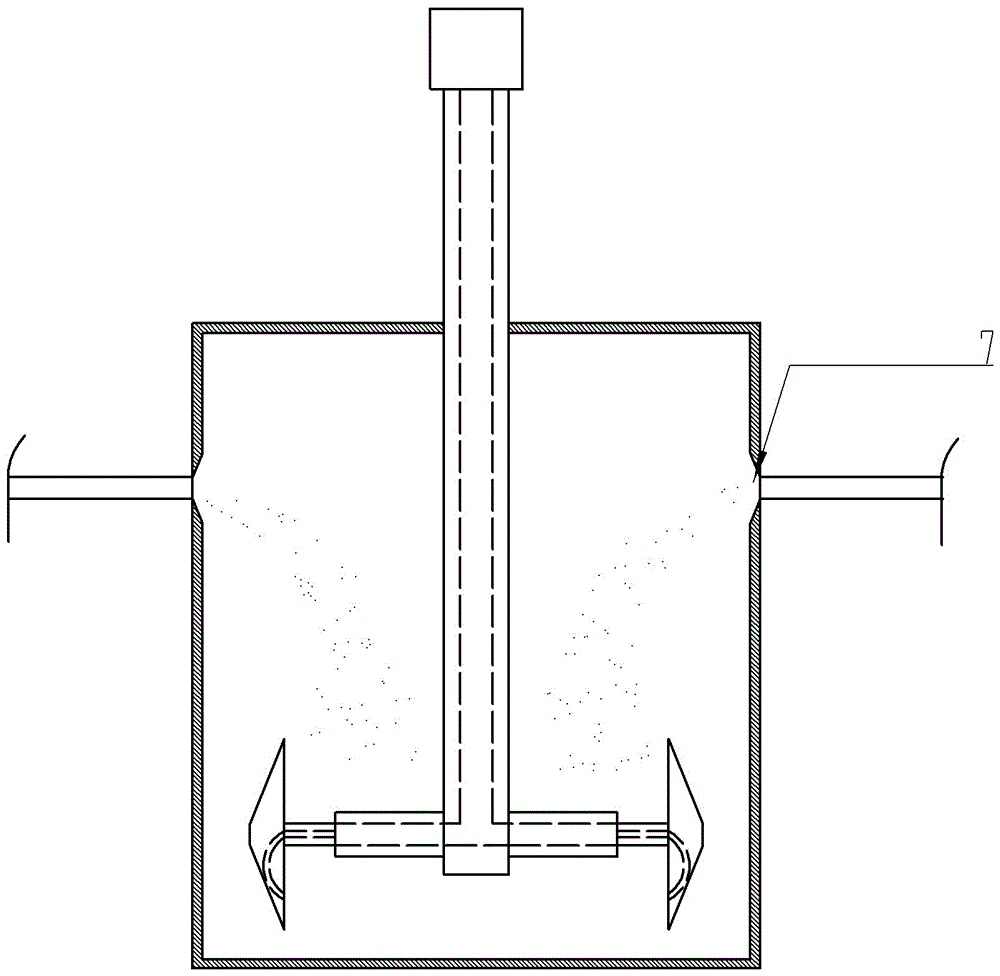

[0028] The stirring device that is used for coating production in embodiment 1, as figure 1 As shown, it includes a housing 2, a stirring shaft 1, and a stirring beam 3 vertically fixed to the stirring shaft 1. The stirring shaft 1 extends into the housing 2 and can be driven by a power mechanism to rotate and reciprocate up and down; the stirring beam 3 The middle part of the stirring shaft 1 is welded on one end of the housing 2, and the stirring beam 3 is perpendicular to the stirring shaft 1; the stirring beam 3 is a hollow sleeve that can be driven by another power mechanism to expand and contract; A stirring part 4 is respectively installed symmetrically around the stirring shaft 1;

[0029] The longitudinal section of the stirring part 4 is trapezoidal, and one side of the long side of the stirring part 4 is connected with the end of the stirring beam 3, and the housing 2 is provided with two through holes 7, which are connected with the respective ends of the two stirr...

Embodiment 2

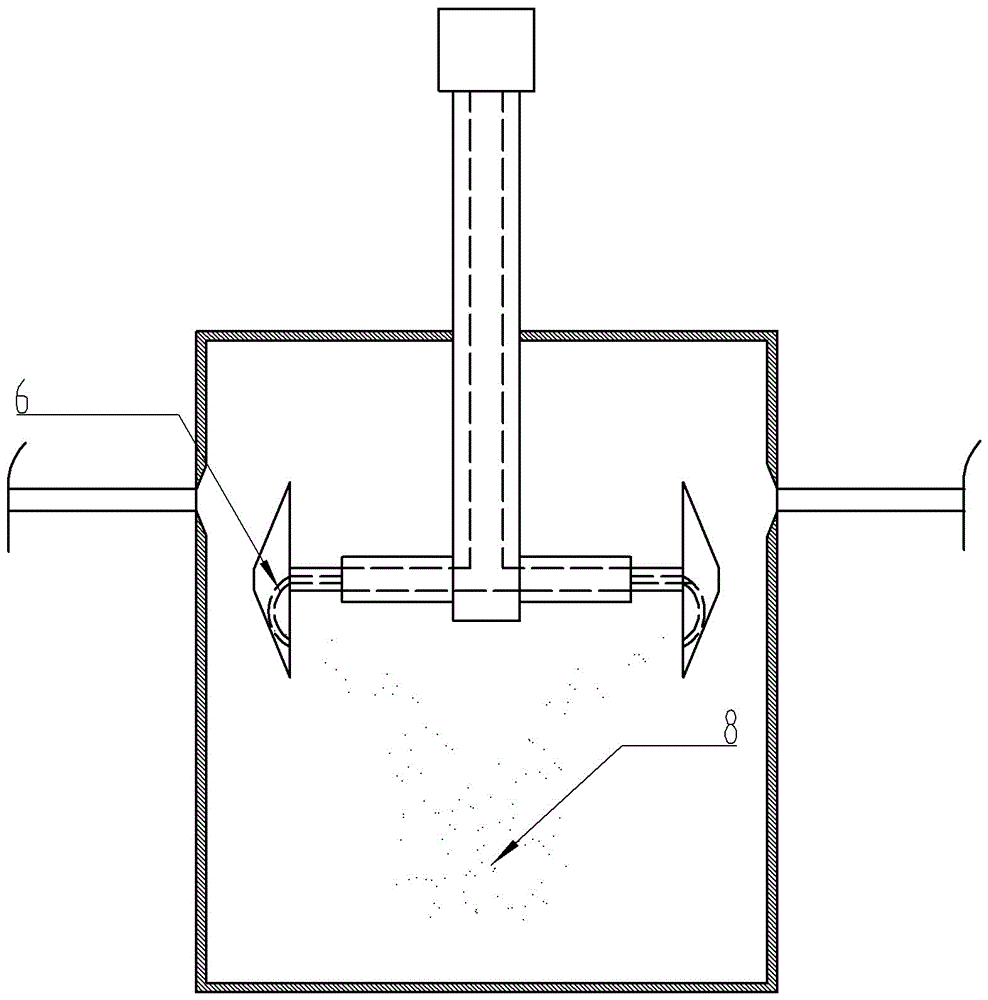

[0036]In this embodiment, the difference from Embodiment 1 is that the stirring part 6 is set as a trapezoidal cover in longitudinal section, supported on the stirring beam 3 by a bracket, and the stirring part 6 does not have an oblique through hole 9;

[0037] The material 8 is directly ejected from the stirring beam 3 and is blocked by the stirring part 6, and the material falls into the shell 2 more dispersedly under the impact.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com