Preparation method of zirconium ball carrier, and application of zirconium ball carrier to manganese-based desulfurizing agent

A technology of desulfurizer and carrier, which is applied in the field of preparation of zirconium ball carrier, can solve the problems of large air resistance and achieve the effects of high space velocity, uniform accumulation and uniform heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

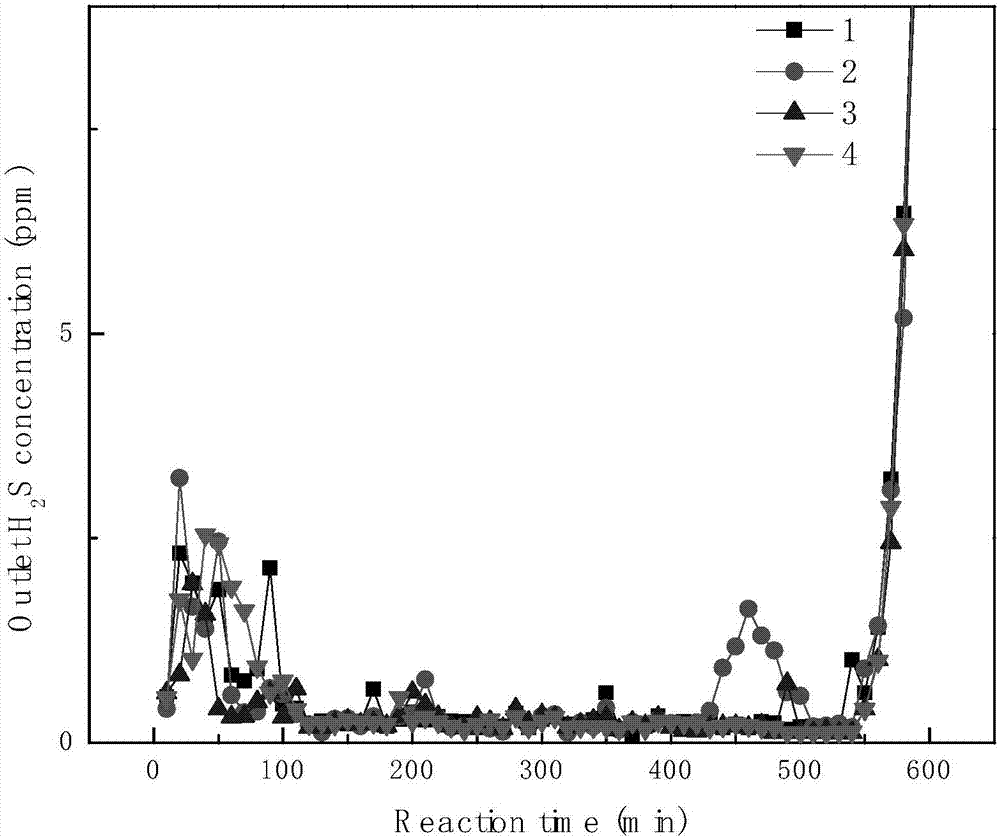

Examples

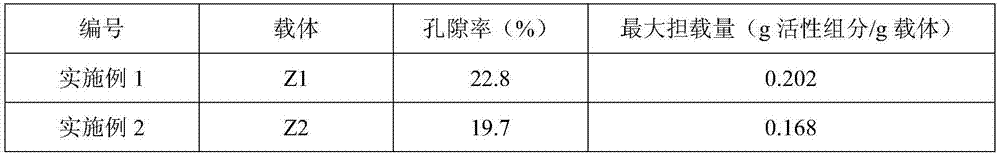

Embodiment 1

[0044] Preparation of carrier: used to illustrate the preparation method of the carrier provided by the present invention.

[0045] 1) Weigh 30g of zirconia, then take 0.525g of nitrogen-methylpyrrolidone, 1.4g of polyethersulfone, and 9.8g of polyvinylpyrrolidone, mix them into a dry and clean ball mill jar equipped with marbles, and mill the jar Fix it on the ball mill to prevent the ball mill tank from being thrown out when the ball mill is working due to loose fixation. After everything is completed, the ball mill will be milled at a speed of 400r / min for 4 hours to obtain a viscous slurry;

[0046] 2) Pour the slurry prepared in step 1) into a medical needle with a measuring range of 10ml, and use a medical needle with a measuring range of 10ml to drip out spherical bodies with a diameter of about 2mm, and drop them into a 500ml beaker filled with water. After dripping, place it in water for 12 hours to make its phase inversion complete. After the phase inversion is compl...

Embodiment 2

[0049] Preparation of carrier: used to illustrate the preparation method of the carrier provided by the present invention.

[0050] 1) Weigh 35g of zirconia, then take 0.525g of nitrogen-methylpyrrolidone, 1.4g of polyethersulfone, and 9.8g of polyvinylpyrrolidone, and mix them into a dry and clean ball mill jar equipped with marbles. Fix it on the ball mill to avoid the ball mill tank being thrown out when the ball mill is working due to loose fixation. After everything is completed, the ball mill will be milled at a speed of 400r / min for 8 hours to obtain a viscous slurry;

[0051] 2) Pour the slurry prepared in step 1) into a medical needle with a measuring range of 10ml, and use a medical needle with a measuring range of 10ml to drip out spherical bodies with a diameter of about 2mm, and drop them into a 500ml beaker filled with water. After dripping, place it in water for 18 hours to make its phase inversion complete. After the phase inversion is complete, remove excess w...

Embodiment 3

[0054] Preparation of carrier: used to illustrate the preparation method of the carrier provided by the present invention.

[0055] 1) Weigh 40g of zirconia, then take 0.525g of nitrogen-methylpyrrolidone, 1.4g of polyethersulfone, and 9.8g of polyvinylpyrrolidone, and mix them into a dry and clean ball mill jar equipped with marbles. Fix it on the ball mill to prevent the ball mill tank from being thrown out when the ball mill is working due to loose fixation. After everything is completed, the ball mill will be milled at a speed of 400r / min for 10 hours to obtain a viscous slurry;

[0056] 2) Pour the slurry prepared in step 1) into a medical needle with a measuring range of 10ml, and use a medical needle with a measuring range of 10ml to drip out spherical bodies with a diameter of about 2mm, and drop them into a 500ml beaker filled with water. After dripping, place it in water for 24 hours to make its phase inversion complete. After the phase inversion is complete, remove ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com