Method for preparing ceramic biological material with abrasion self-remediation function in in-vivo environment

A technology of internal environment and biomaterials, applied in the field of biomedical engineering and biomedical materials, can solve problems affecting the quality of life of patients, abnormal noise of artificial organs, large friction coefficient, etc., achieve good lubrication, improve quality of life, and increase usage The effect of longevity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

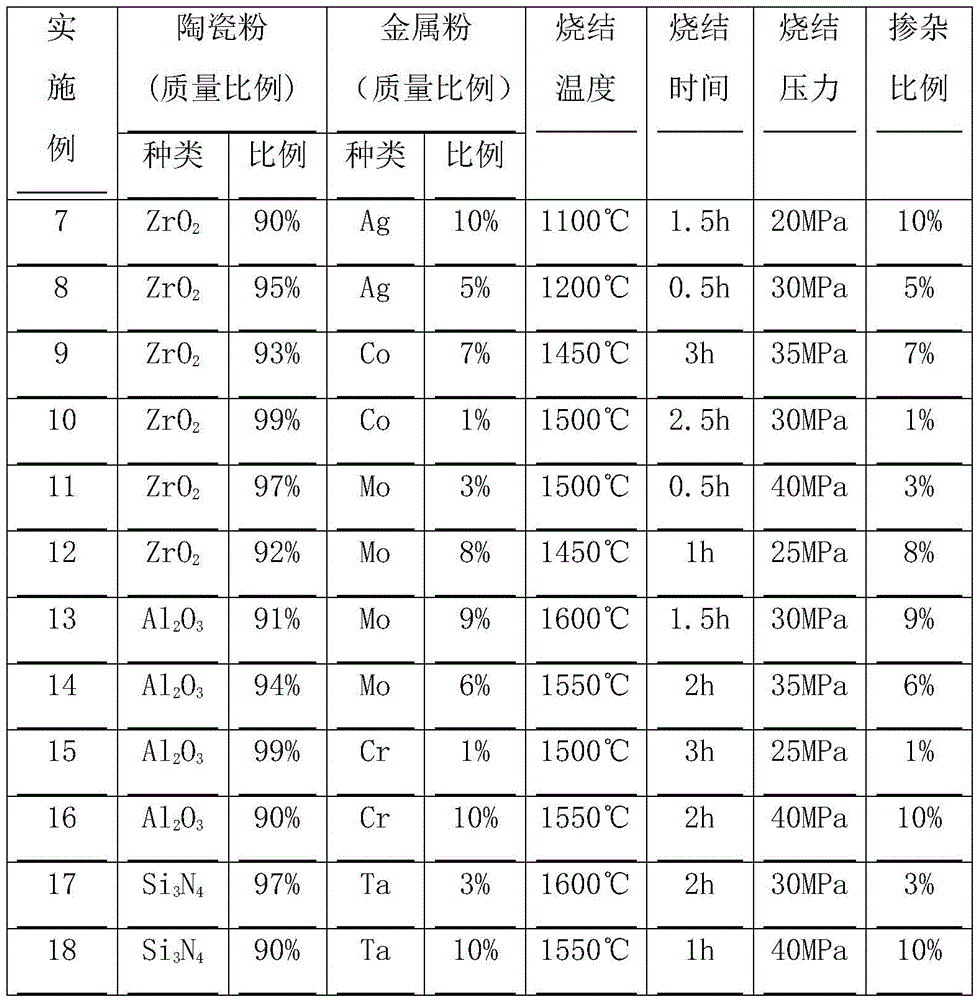

Examples

Embodiment 1

[0021] A. Raw material preparation: Copper powder and zirconia powder are used as raw materials, and the ratio is recorded as: 99% zirconia powder and 1% copper powder according to mass percentage. Mix the powder raw materials evenly in a planetary ball mill.

[0022] B. Put the dry raw material powder into a graphite mold, and carry out hot-press sintering under the protection of argon. The reaction hot-press sintering temperature is 1100°C, the hot-press sintering time is 2 hours, and the hot-press sintering pressure is 25MPa. A zirconia ceramic biomaterial doped with metal copper and capable of self-repairing wear in vivo, wherein the doping ratio of metal copper is 1%, and the ceramic density reaches more than 90%.

Embodiment 2

[0024] A. Raw material preparation: Copper powder and zirconia powder are used as raw materials, and the ratio is recorded as: 90% zirconia powder and 10% copper powder according to mass percentage. Mix the powder raw materials evenly in a planetary ball mill.

[0025] B. Put the dry raw material powder into a graphite mold, and carry out hot-press sintering under the protection of argon. The reaction hot-press sintering temperature is 1100°C, the hot-press sintering time is 3 hours, and the hot-press sintering pressure is 30MPa. A zirconia ceramic biomaterial doped with metal copper and capable of self-repairing wear in vivo, wherein the doping ratio of metal copper is 10%, and the density of the ceramic reaches more than 90%.

Embodiment 3

[0027] A. Raw material preparation: chromium powder and zirconia powder are used as raw materials, and the ratio is recorded as: 99% zirconia powder and 1% chromium powder according to mass percentage. Mix the powder raw materials evenly in a planetary ball mill.

[0028] B. Put the dry raw material powder into a graphite mold, and carry out hot-press sintering under the protection of argon. The reaction hot-press sintering temperature is 1400°C, the hot-press sintering time is 3 hours, and the hot-press sintering pressure is 25MPa. A zirconia ceramic biomaterial doped with metal chromium and capable of self-repairing wear in vivo, wherein the doping ratio of metal chromium is 1%, and the density of the ceramic reaches more than 90%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com